Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

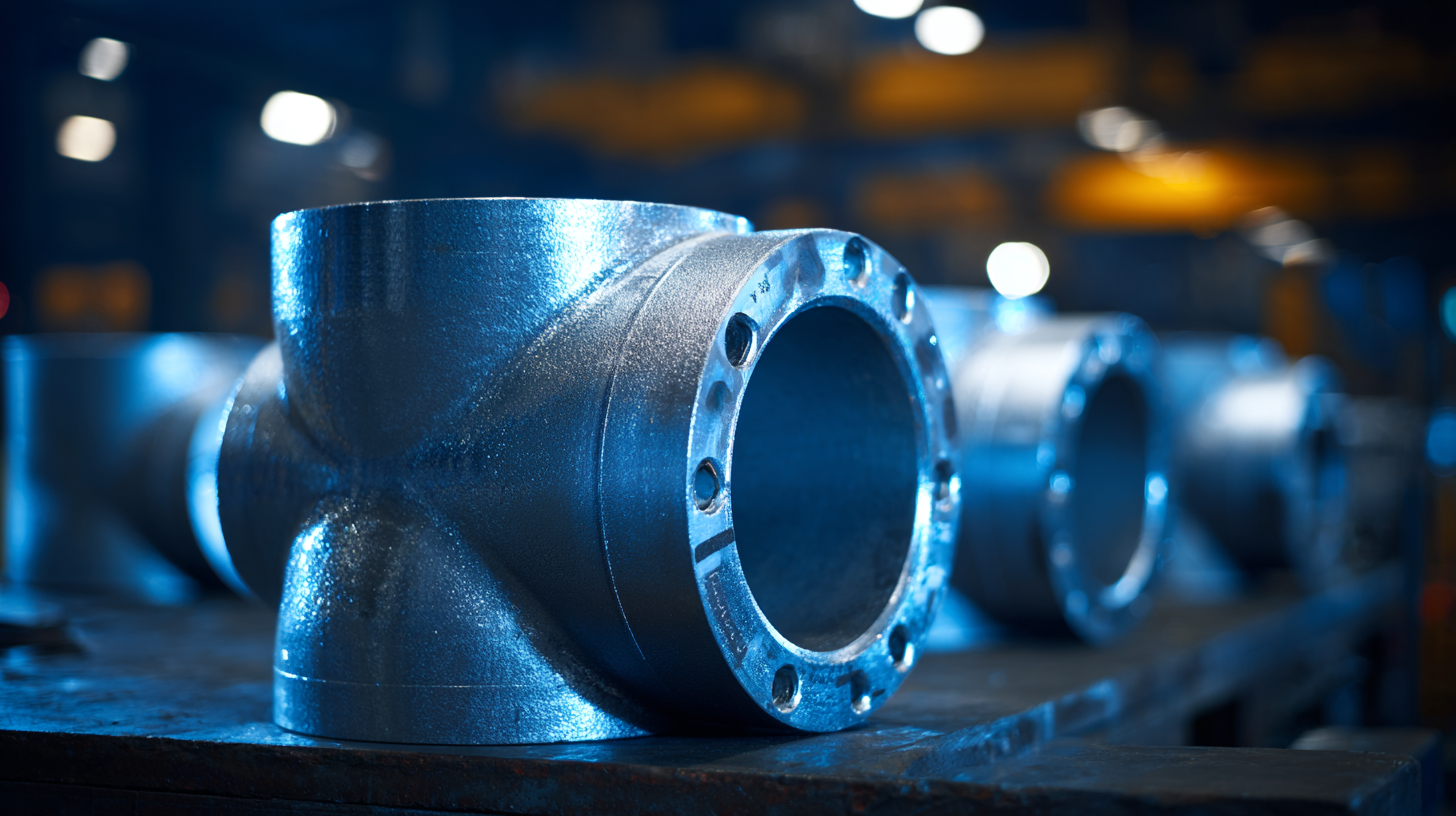

What Are Weld Fittings? Exploring Their Types and Industry Applications with Key Data Insights

Weld fittings are essential components in various piping systems, serving as critical junctions that connect pipes, valves, and other equipment in industries such as oil and gas, construction, and manufacturing.

According to a report by Markets and Markets, the global welded fittings market is projected to reach USD 4.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.2% from 2020 to 2025.

This growth reflects the increasing demand for durable and robust piping solutions that can withstand high pressure and extreme temperatures.

In this blog, we will explore the different types of weld fittings available, their unique properties, and their diverse applications across various industries.

Understanding these components is key for professionals looking to enhance the efficiency and safety of their piping systems while being informed by key data insights that influence market trends and innovations.

Weld fittings are essential components in various piping systems, serving as critical junctions that connect pipes, valves, and other equipment in industries such as oil and gas, construction, and manufacturing.

According to a report by Markets and Markets, the global welded fittings market is projected to reach USD 4.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.2% from 2020 to 2025.

This growth reflects the increasing demand for durable and robust piping solutions that can withstand high pressure and extreme temperatures.

In this blog, we will explore the different types of weld fittings available, their unique properties, and their diverse applications across various industries.

Understanding these components is key for professionals looking to enhance the efficiency and safety of their piping systems while being informed by key data insights that influence market trends and innovations.

The Importance of Weld Fittings in Modern Construction and Manufacturing

Weld fittings play a crucial role in modern construction and manufacturing, serving as essential components that ensure the integrity and durability of various systems. These fittings, which are welded to pipes and structures, provide robust connections that can withstand high pressure and extreme conditions. The importance of weld fittings cannot be overstated, as they contribute significantly to the structural reliability of buildings, bridges, and industrial facilities. By using different types of weld fittings, engineers can tailor systems for optimal performance while ensuring safety standards are met.

Weld fittings play a crucial role in modern construction and manufacturing, serving as essential components that ensure the integrity and durability of various systems. These fittings, which are welded to pipes and structures, provide robust connections that can withstand high pressure and extreme conditions. The importance of weld fittings cannot be overstated, as they contribute significantly to the structural reliability of buildings, bridges, and industrial facilities. By using different types of weld fittings, engineers can tailor systems for optimal performance while ensuring safety standards are met.

In parallel, the need for specialized equipment, such as personal protective equipment (PPE), emphasizes the importance of safety in construction and manufacturing environments. Designing PPE that accommodates the unique needs of women enhances comfort and effectiveness, much like how well-designed weld fittings enhance system performance. Both weld fittings and appropriately designed PPE are vital for fostering a safe and efficient workplace, ultimately resulting in better outcomes and reducing the risk of accidents and failures in construction projects. Attention to detail in both areas ensures that industries can operate smoothly while prioritizing the well-being of their workforce.

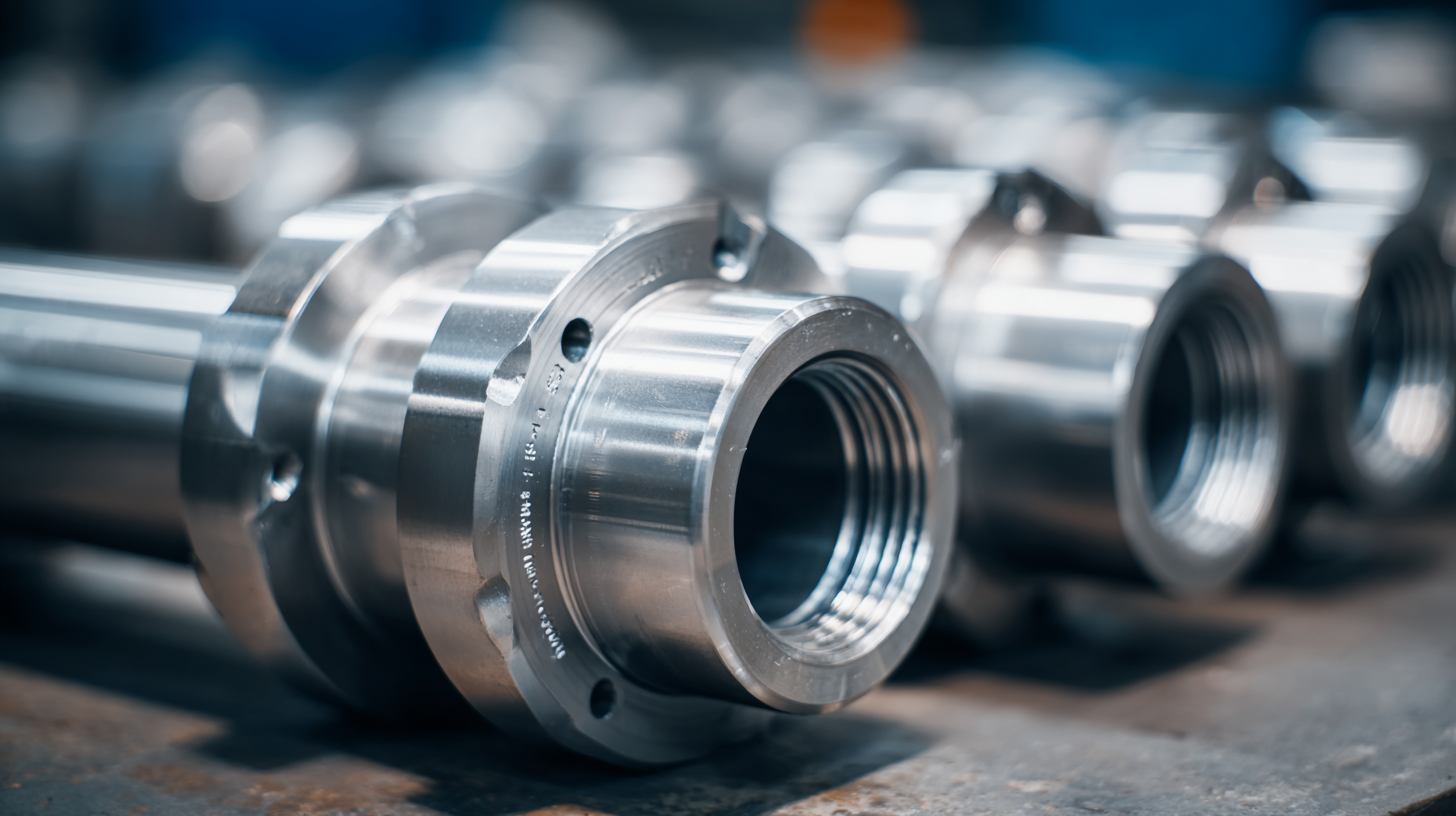

Types of Weld Fittings: A Comprehensive Overview and Their Unique Characteristics

Weld fittings are critical components in various industries, aiding in the seamless joining of pipes and equipment. These fittings come in various types, including elbows, tees, reducers, and caps, each serving unique functions dictated by their structural characteristics. For example, the strength of a weld fitting is often influenced by its design and the materials used; recent studies have highlighted that components fabricated from composite materials can significantly enhance performance due to their superior mechanical properties compared to traditional metal fittings. Specific data suggests that the use of advanced composite materials in automotive applications can reduce weight by 30% while maintaining robustness, showcasing the potential for innovation in weld fitting technologies.

In sectors like nuclear engineering, understanding the microstructures and mechanical properties of welds in reactor pressure vessels (RPVs) is paramount. A comprehensive review revealed that variations in welding techniques can lead to significant differences in the performance and longevity of these critical components, especially under irradiation effects. This research underscores the importance of continuous monitoring and classification of weld types, reflecting a broader trend within the industry toward enhanced safety protocols and improved performance metrics. As technologies evolve, integrating modern manufacturing techniques, such as laser welding and metal additive manufacturing, also presents opportunities for creating weld fittings with better precision and durability, further pushing the boundaries of traditional welding practices.

Types of Weld Fittings and Their Industry Applications

Industry Applications of Weld Fittings: From Oil & Gas to HVAC Systems

Weld fittings play a crucial role across various industries, particularly in oil and gas, HVAC systems, and construction. For instance, the Americas pipe fittings market is expanding rapidly due to increased demand driven by energy and construction sectors. Recent reports project significant growth in the mechanical tube and pipe market, with a focus on welded steel tubes and their applications within these sectors. This evolving landscape opens numerous opportunities for businesses that rely on robust piping systems to support critical infrastructure.

In the oil and gas sector, welded fittings are essential for ensuring leak-proof connections under high pressure. The global carbon steel pipe fittings market, projected to grow substantially by 2030, highlights the importance of these components in managing the complexities of modern piping systems. Similarly, HVAC systems benefit from advanced welding techniques, ensuring efficient operation and longevity of installations, particularly in copper piping applications.

Tips: When selecting weld fittings, prioritize those made with high-quality materials to enhance durability and resist corrosion. Additionally, consider investing in advanced welding technologies, such as hydraulic pressing tools, which can significantly improve installation efficiency and reliability. Lastly, staying informed about industry trends and emerging technologies can provide a competitive edge in an evolving market.

Key Data Insights: Market Trends and Growth Forecast for Weld Fittings

The market for weld fittings is witnessing significant growth, driven by increasing demand across various industries, including oil and gas, construction, and water treatment. Key data insights indicate that the global weld fittings market is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is fueled by the rising need for durable and efficient piping solutions capable of withstanding high pressures and temperatures.

To navigate this evolving market, industry players must keep an eye on emerging trends such as the integration of advanced materials and technologies. For instance, the increasing adoption of corrosion-resistant fittings is crucial, especially in harsh environments.

**Tip:** When selecting weld fittings, consider not only the material but also the specific application requirements. This ensures optimal performance and longevity. Moreover, staying updated on regulatory changes can help manufacturers align their production processes with the latest industry standards, ensuring compliance and fostering trust among clients.

Choosing the Right Weld Fitting: Factors and Standards in Various Industries

When selecting the right weld fitting for a specific application, it is vital to consider various factors that affect performance and safety across different industries. The choice of material, connection type, and industry standards play a crucial role. For instance, in the case of piping systems, adherence to standards like ASME B31.3 ensures that the fittings used will withstand operational stresses and environmental conditions, thus enhancing safety and technical performance.

Moreover, advancements in welding technology, such as the optimization of ultrasonic welding parameters, illustrate the importance of precise techniques in manufacturing. This research highlights the necessity of tailored approaches to process settings to achieve superior wire terminations, particularly in critical applications like automotive electrical systems. As industries evolve, staying informed about the latest safety regulations and technological innovations will empower professionals to make informed choices about weld fittings, ensuring both functionality and compliance with safety standards.

What Are Weld Fittings? Exploring Their Types and Industry Applications with Key Data Insights

| Type of Weld Fitting | Material | Industry Applications | Standard Compliance | Connection Size (inches) |

|---|---|---|---|---|

| Elbow | Carbon Steel | Oil & Gas, Plumbing | ASME, ASTM | 1/2 - 24 |

| Tee | Stainless Steel | Food Processing, Chemical | ISO, ANSI | 1/2 - 16 |

| Cross | PVC | Irrigation, Water Supply | ASTM D1784 | 1 - 4 |

| Reducer | Alloy Steel | Power Generation, HVAC | MSS, ASME | 1/2 - 12 |

| Cap | Copper | Electrical, Plumbing | IEC, UL | 1/2 - 10 |

Related Posts

-

A Comprehensive Guide to Choosing the Right Weld Fittings for Your Projects

-

Exploring Alternative Weld Fittings: Innovative Solutions for Global Procurement Needs

-

The Role of Butterfly Valves in Modern Industry: A Comprehensive Overview

-

Comparative Analysis of Steel Flanges: Key Specifications & Market Trends for Global Buyers

-

Maximizing Efficiency and Longevity with Titan Valves in Industrial Applications

-

How to Choose the Right Stainless Valves for Your Industrial Applications