Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

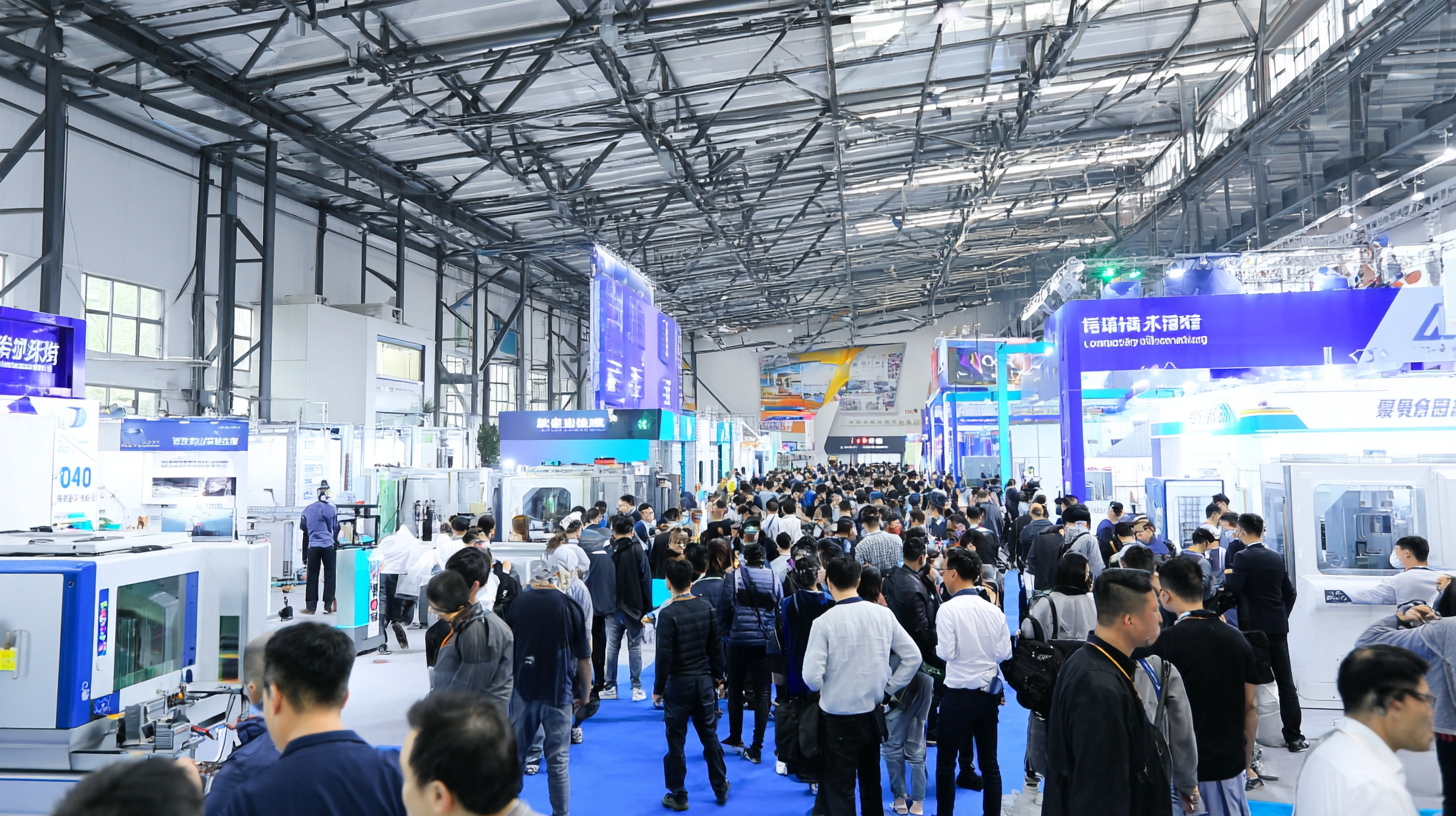

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025

The 138th China Import and Export Fair in 2025 presents a pivotal platform for showcasing cutting-edge innovations and trends in various industries, with a particular spotlight on weld bend technologies. As manufacturers and suppliers converge to explore emerging market demands, the significance of weld bend solutions is set to take center stage, reflecting advancements in welding techniques and material applications. This event not only underscores the evolution of manufacturing processes but also highlights how weld bend innovations contribute to enhanced durability, efficiency, and sustainability in production.

With a diverse array of exhibitors and participants, the fair offers an invaluable opportunity for industry professionals to exchange insights and identify potential collaborations, ensuring that weld bend technologies remain at the forefront of industrial progress. As we delve into this dynamic environment, we will explore the latest developments and industry trends that are shaping the future of weld bend practices.

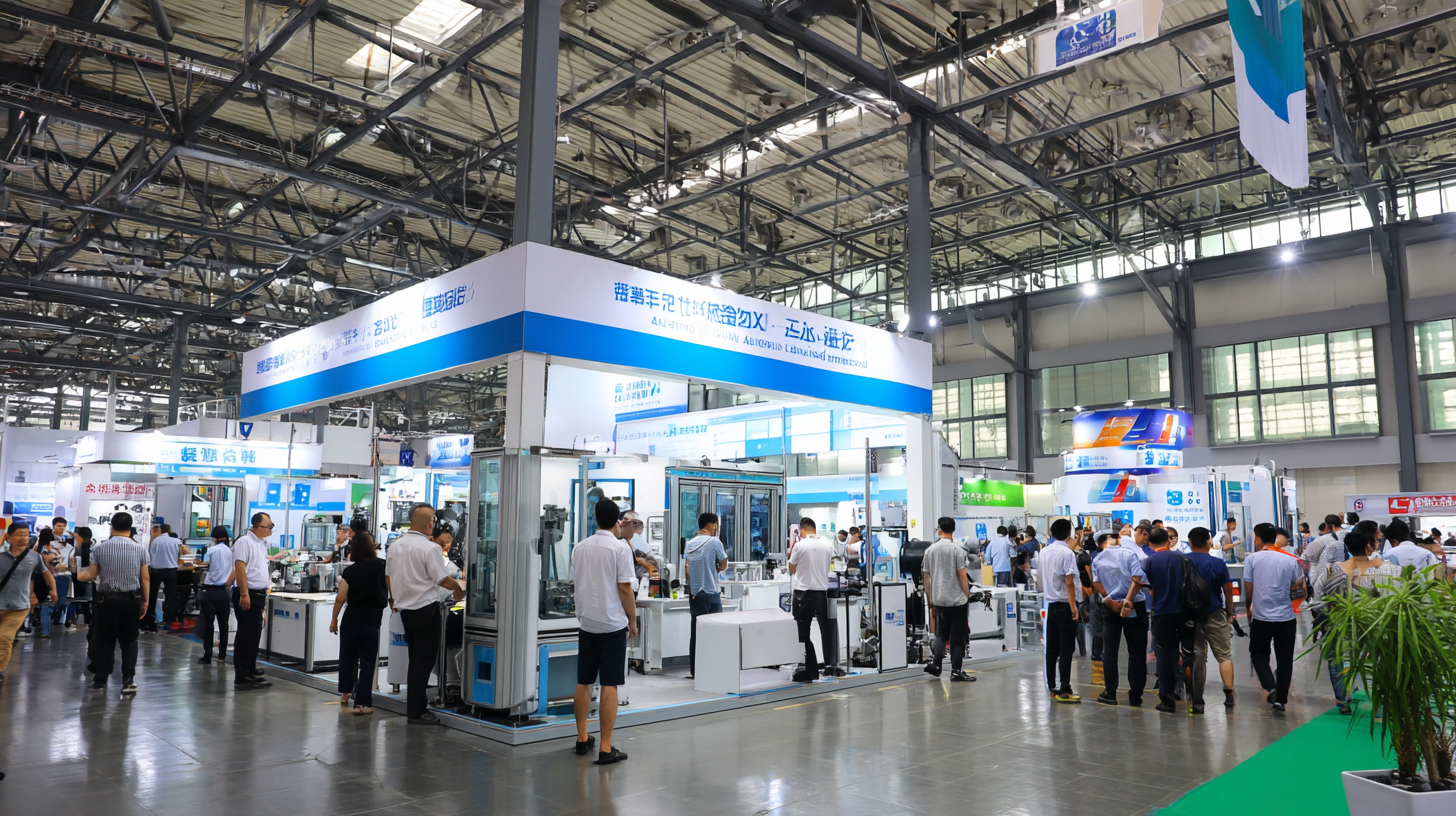

Weld Bend Innovations: Key Highlights from the 138th China Import and Export Fair

At the 138th China Import and Export Fair, the spotlight shone brightly on the latest innovations in weld bend technology, showcasing how this sector is evolving to meet the demands of modern manufacturing. Industry reports highlight that the global welding equipment market is projected to reach $21.89 billion by 2027, reflecting a CAGR of 5.4%. Such growth underscores the importance of advancements in welding techniques, particularly with the increasing emphasis on efficiency and quality in production processes.

One of the key highlights from the fair was the introduction of automated weld bending solutions. Companies are increasingly turning to robotics to enhance precision in welding, which is crucial for industries like automotive and aerospace, where even the slightest imperfections can lead to significant safety concerns. For instance, a recent study indicated that automated welding systems can enhance throughput by up to 30%, benefiting manufacturers looking to optimize their processes.

**Tips:** When exploring welding innovations, consider investing in training for your workforce to ensure they are up-to-date with the latest technologies. Additionally, look into integrating smart technology into your operations, as it not only improves efficiency but also contributes to data-driven decision-making. Keeping an eye on industry trends will help you stay ahead in a competitive market.

Emerging Trends in Welding Technology Showcased at the 2025 Canton Fair

The 138th China Import and Export Fair in 2025 is set to highlight significant advancements in welding technology, a sector poised for rapid growth. According to a recent report by Markets and Markets, the global welding market is projected to reach $28.6 billion by 2027, growing at a CAGR of 6.2% from 2022. This growth is attributed to the increasing demand for advanced welding processes to improve productivity and efficiency in manufacturing, particularly in sectors such as automotive and construction.

At the Canton Fair, several emerging trends in welding technology will be on display, including the adoption of automation and robotics. Industry professionals have noted that automated welding solutions can increase precision and reduce waste, which is critical in today’s environmentally conscious market. Additionally, the integration of AI in welding processes is becoming more prevalent, with a report from Mordor Intelligence predicting that the AI in welding market will expand significantly, driven by the need for smart manufacturing solutions. These innovations not only enhance the quality of welds but also optimize overall production timelines, marking a transformative shift in the welding landscape.

Emerging Trends in Welding Technology at the 138th China Import and Export Fair 2025

Impact of Industry 4.0 on Weld Bend Products at the China Import and Export Fair

The 138th China Import and Export Fair in 2025 will serve as a significant platform for showcasing the latest innovations in weld bend products, highlighting the profound impact of Industry 4.0 on this sector. As the manufacturing landscape evolves, the integration of smart technologies—such as the Internet of Things (IoT), artificial intelligence, and advanced robotics—has revolutionized traditional welding practices. These advancements not only enhance the precision and efficiency of weld bending processes but also facilitate real-time monitoring and predictive maintenance, ultimately resulting in superior product quality and reduced operational costs.

In this transformative environment, manufacturers are increasingly adopting automated solutions that streamline production workflows and minimize human error. The fair will feature discussions and presentations focusing on how data-driven insights are reshaping product development and customer engagement in the weld bend industry. Key players will demonstrate their commitment to sustainability by showcasing eco-friendly welding materials and processes, underscoring the industry's shift toward greener manufacturing practices while aligning with global sustainability goals. Attendees can expect to witness firsthand the synergy between innovation and sustainability as they explore new products and technologies that promise to define the future of weld bending.

Networking Opportunities for Weld Bend Industry Leaders at the 138th Fair

At the upcoming 138th China Import and Export Fair in 2025, industry leaders from the Weld Bend sector will have unparalleled networking opportunities to connect, share insights, and foster collaborations. This event will serve as a melting pot for innovators and seasoned professionals alike, where the latest advancements in welding technology and market trends will take center stage. Attendees can expect to engage in dynamic discussions and collaborative workshops that will elevate their understanding of the industry.

In addition to planned seminars and keynote speeches, the fair will also facilitate pre-arranged matchmaking sessions to streamline interactions between participants. These networking efforts not only benefit established companies but also provide a platform for new players in the market to showcase their ideas and products. Such interactions can lead to partnerships that help drive innovation and growth within the Weld Bend industry, making the fair a vital event for anyone looking to stay ahead in this rapidly evolving market.

Sustainability and Efficiency: The Future of Weld Bend Practices in 2025

As the world moves towards sustainability, the welding and bending industry is set to undergo significant transformations by 2025. The integration of green technologies into weld bend practices focuses on reducing waste and energy consumption. Innovations in metal sheet bending machines, expected to grow substantially, emphasize efficiency while maintaining quality. The projected increase in market size reflects the industry's adaptation to more sustainable practices, which align with global environmental goals.

In the realm of modular construction, structural steel plays a pivotal role in enhancing both sustainability and efficiency. By utilizing advanced bending and welding techniques, manufacturers can create prefabricated components that reduce material wastage and optimize production timelines. This shift not only meets the rising demand for environmentally friendly construction solutions but also supports the industry's transition towards a circular economy. As these trends unfold at events like the 138th China Import and Export Fair, industry stakeholders will gain valuable insights into shaping a more sustainable future in weld bend practices.

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025

| Innovation/Trend | Description | Impact on Sustainability | Efficiency Improvement | Year of Implementation |

|---|---|---|---|---|

| Advanced Welding Materials | Utilization of lighter and stronger materials for welding processes. | Reduces waste and enhances durability. | Increases overall weld strength and performance. | 2025 |

| Robotic Welding Automation | Incorporating robotics for precision welding tasks. | Minimizes human error and ensures consistent quality. | Reduces cycle times significantly. | 2025 |

| Eco-Friendly Welding Techniques | Processes that minimize emissions and energy consumption. | Promotes environmental sustainability. | Improves energy efficiency. | 2025 |

| Smart Welding Solutions | Integration of IoT and AI in monitoring welding processes. | Enhances tracking of material use and waste. | Increases productivity through data analytics. | 2025 |

| Training and Skill Development | Programs focused on improving welding skills. | Encourages responsible material practices. | Reduces rework and increases overall quality. | 2025 |

Related Posts

-

Exploring Alternative Weld Fittings: Innovative Solutions for Global Procurement Needs

-

How to Choose the Right Flange Valves for Your Industrial Needs

-

How to Choose the Right Needle Valve for Global Industrial Applications

-

5 Key Factors for Sourcing the Best Flanges and Fittings in Today's Global Market

-

Maximizing Efficiency and Longevity with Titan Valves in Industrial Applications

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications