Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

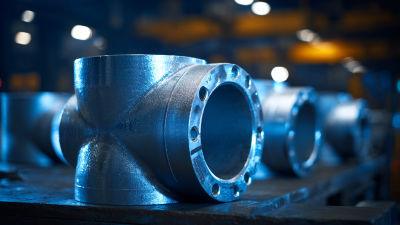

Understanding Flange Fittings: Essential Guide for Efficient Piping Systems

Flange fittings are critical components in modern piping systems, serving to connect various piping segments and facilitate the efficient flow of liquids and gases. According to a report by the Global Flanges Market, the demand for flange fittings is projected to grow at a CAGR of 4.5% from 2021 to 2028, driven by the increasing investments in infrastructure and industrial projects worldwide. These fittings play a pivotal role in maintaining system integrity and ensuring tight seals, which are essential to prevent leaks and enhance operational safety. As industries such as oil and gas, water treatment, and pharmaceuticals continue to expand, understanding the types and applications of flange fittings becomes imperative for engineers and project managers alike. This guide aims to provide an in-depth exploration of flange fittings, highlighting their significance in achieving efficient and reliable piping systems.

Types of Flange Fittings: An Overview of Common Variants in Piping Systems

Flange fittings are crucial components in piping systems, serving as connectors that facilitate the flow of various fluids. Among the most common types of flange fittings are weld neck, slip-on, blind, and threaded flanges, each designed for specific applications. For instance, weld neck flanges are commonly used in high-pressure environments due to their robustness and ability to distribute stress evenly, making them ideal for industries like oil and gas. According to a report by ResearchAndMarkets, the global flanges market is projected to reach USD 8.9 billion by 2025, driven by increasing demand in infrastructure and manufacturing sectors.

Slip-on flanges, on the other hand, are popular for their ease of installation and cost-effectiveness. They are often used in low-pressure systems, offering convenience without compromising on performance. A recent study indicated that over 40% of piping systems utilize slip-on flanges due to their versatility across diverse industries. Additionally, blind flanges play a vital role in maintenance, providing a convenient way to seal off ends of piping systems when required, thus ensuring safety and operational efficiency. As these fittings continue to evolve, understanding their differences and applications becomes essential for optimizing piping systems.

Material Specifications: Understanding the Impact of Steel, PVC, and Other Components

When selecting materials for flange fittings in piping systems, understanding the implications of using Steel versus PVC is essential. Recent studies have highlighted the mechanical properties of various polymers, such as PLA, ABS, and epoxy resin, which are increasingly being used in 3D printing technologies for creating efficient parts. The ongoing concern regarding PVC, particularly in drinking water applications, raises significant health considerations, with reports indicating that chemicals from PVC can leach into water systems. This indicates a pressing need to explore alternatives like stainless steel, which offer both durability and safety for potable water systems.

When selecting materials for flange fittings in piping systems, understanding the implications of using Steel versus PVC is essential. Recent studies have highlighted the mechanical properties of various polymers, such as PLA, ABS, and epoxy resin, which are increasingly being used in 3D printing technologies for creating efficient parts. The ongoing concern regarding PVC, particularly in drinking water applications, raises significant health considerations, with reports indicating that chemicals from PVC can leach into water systems. This indicates a pressing need to explore alternatives like stainless steel, which offer both durability and safety for potable water systems.

Tip: When deciding on flange fittings, consider the type of application and whether the material can withstand the operational conditions without compromising health safety. For example, stainless steel is not only strong but also resistant to corrosion and leaching.

In the context of sustainability, the blending of PVC with biocompatible PCL showcases innovative advances in material science, potentially enhancing mechanical properties while addressing health concerns. However, sustainability assessments demonstrate that while PVC has been a staple in urban water systems, its classification as hazardous waste could hinder progress towards zero-waste goals. This makes it increasingly vital for industries to rethink material choices, leaning towards safer alternatives without sacrificing performance.

Tip: Stay informed about evolving material technologies and consider products that meet safety standards and sustainability goals, ensuring that your piping systems are both efficient and environmentally friendly.

Flange Size and Pressure Ratings: Ensuring Compatibility and Safety in Design

When designing piping systems, understanding flange size and pressure ratings is crucial for ensuring compatibility and safety. Different applications require specific flange dimensions, which are determined by the pipeline's diameter and the fluid's properties. Standardized flange sizes, defined by organizations like ASME and ANSI, facilitate seamless integration between various components. Using the correct flange size not only ensures a proper fit but also minimizes the risk of leaks and failures under pressure.

In addition to size, pressure ratings are essential for safe operation. Flanges come with distinct pressure ratings that indicate the maximum pressure they can withstand at a given temperature. These ratings, expressed in psi or bar, help engineers select appropriate materials and designs based on operating conditions. Failing to account for pressure ratings can lead to catastrophic failures, posing risks to both personnel and equipment. Therefore, it is vital to match flange ratings with system pressure requirements to maintain the structural integrity and safety of piping systems.

Flange Size and Pressure Ratings Comparison

This chart illustrates the compatibility between flange sizes and their respective pressure ratings, which is crucial for ensuring safety in piping system designs.

Installation Techniques: Best Practices for Secure Flange Connections

When it comes to installing flange fittings in piping systems, adhering to best practices is crucial for ensuring secure connections. One effective technique is to always inspect the surfaces of the flanges for any debris or irregularities before installation. Clean, flat surfaces promote a better seal and reduce the risk of leaks. When assembling the flanges, evenly tighten the bolts in a crisscross pattern to distribute pressure uniformly, which helps maintain the integrity of the connection.

Additionally, using the right tools is paramount in achieving a successful installation. Ensure that you have the appropriate torque wrench to tighten bolts to the manufacturer’s specifications, as improper torque can lead to joint failure. Taking safety precautions, such as wearing gloves and eye protection, is also essential to prevent injuries during the installation process. By following these techniques, you can significantly enhance the reliability of your piping systems while minimizing potential hazards.

Common Applications: Flange Fittings in Oil, Gas, and Water Distribution Systems

Flange fittings play a critical role in the efficient transport of fluids in various industries, particularly in oil, gas, and water distribution systems. According to the Global Flange Market Report, the demand for flange fittings is expected to grow at a CAGR of 5.4% through 2026, primarily driven by the increasing need for enhanced infrastructure and advancements in technology within these sectors. Flanges provide a robust solution for creating leak-proof connections, allowing for easy assembly and disassembly, which is essential in maintenance operations across pipeline networks.

Flange fittings play a critical role in the efficient transport of fluids in various industries, particularly in oil, gas, and water distribution systems. According to the Global Flange Market Report, the demand for flange fittings is expected to grow at a CAGR of 5.4% through 2026, primarily driven by the increasing need for enhanced infrastructure and advancements in technology within these sectors. Flanges provide a robust solution for creating leak-proof connections, allowing for easy assembly and disassembly, which is essential in maintenance operations across pipeline networks.

In oil and gas distribution, flanges are indispensable for ensuring high-pressure and high-temperature operations. The International Energy Agency (IEA) reports that global oil demand is projected to reach 106 million barrels per day by 2028, which intensifies the need for reliable piping systems that employ robust flange fittings to handle such pressures. Similarly, in water distribution, the Environmental Protection Agency highlights that approximately 20% of treated water is lost due to leakage in aging infrastructure, emphasizing the importance of effective flanged connections that can withstand varying conditions to minimize water loss. Thus, understanding the applications and benefits of flange fittings is crucial for achieving operational efficiency in these vital industries.

Related Posts

-

What Are Weld Fittings? Exploring Their Types and Industry Applications with Key Data Insights

-

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry with Key Market Insights

-

10 Essential Tips for Choosing the Right Flanges and Fittings

-

Top Strategies for Sourcing High Quality Steel Fittings

-

The Future of Steel and Fittings Innovation Trends Data and Best Practices

-

How to Choose the Right Flange Valves for Your Industrial Needs