Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

The Essential Guide to Understanding Check Valves: Types, Applications, and Maintenance Tips

Check valves play a crucial role in various fluid systems, ensuring that flow only moves in one direction while preventing backflow. This essential guide aims to demystify check valves by exploring the different types available, their specific applications, and key maintenance tips to ensure optimal performance. Understanding the functionality of check valves is vital for engineers and technicians alike, as these components are integral to the efficiency and safety of many industrial operations.

Check valves play a crucial role in various fluid systems, ensuring that flow only moves in one direction while preventing backflow. This essential guide aims to demystify check valves by exploring the different types available, their specific applications, and key maintenance tips to ensure optimal performance. Understanding the functionality of check valves is vital for engineers and technicians alike, as these components are integral to the efficiency and safety of many industrial operations.

Through this comprehensive overview, readers will gain insights into how to select the right check valve for their needs, recognize the signs of wear and tear, and implement best practices for maintenance. By enhancing your knowledge of check valves, you can safeguard your systems, minimize downtime, and extend the lifespan of your equipment.

Types of Check Valves: An Overview of Common Variants

Check valves are crucial components in various fluid systems, ensuring that flow occurs in one direction while preventing backflow. There are several common types of check valves, each designed to address specific applications and operational environments. The most frequently used variants include ball check valves, swing check valves, and diaphragm check valves.

Ball check valves are designed with a spherical ball that blocks reverse flow when the fluid pressure drops. This type is particularly effective in applications involving slurries or fluids with solids, as the spherical design minimizes blockage.

Swing check valves, on the other hand, feature a hinged disc that swings open with forward flow and swings closed when the flow reverses. They are ideal for applications where space is limited and can handle larger flow rates effectively.

Lastly, diaphragm check valves utilize a flexible diaphragm that opens and closes with pressure changes, making them suitable for sensitive applications, such as in water treatment or food processing.

Each type of check valve has its unique benefits that cater to specific needs, making it essential to select the right one for your application. Understanding these types can enhance the efficiency and reliability of fluid systems, ensuring optimal performance over time.

Common Materials Used in Check Valve Construction

Check valves are critical components in various fluid systems, and their construction materials significantly influence performance and durability. Commonly, check valves are made from metals like stainless steel and brass, which are favored for their strength and resistance to corrosion. Stainless steel, in particular, is ideal for applications involving aggressive fluids or high temperatures, while brass offers a good balance of affordability and mechanical properties for less demanding environments.

In addition to metals, thermoplastics such as PVC and CPVC are also widely used in check valve construction, especially in chemical processing and drainage applications. These materials are lightweight, resistant to chemical damage, and can handle a wide range of temperatures. When selecting a check valve, it is crucial to consider the material's compatibility with the fluid, pressure requirements, and potential environmental factors, ensuring optimal performance and longevity in the intended application.

Applications of Check Valves in Various Industries

Check valves play a crucial role in various industries by preventing backflow and ensuring the smooth operation of fluid systems. In the water and wastewater sector, check valves are essential for protecting pumps and maintaining system integrity. They allow water to flow in one direction while preventing reverse flow that could lead to contamination or system failures. This application is vital in municipal water supply systems, where the quality and reliability of water delivery are paramount.

In the oil and gas industry, check valves are used to safeguard pipelines and processing equipment. They help maintain pressure and keep crude oil or natural gas flowing in the desired direction during transportation. This is particularly important in offshore drilling operations, where the risk of backflow can result in serious leaks and operational hazards.

Additionally, check valves find applications in manufacturing processes, such as chemical production, where they ensure that toxic substances do not accidentally flow back into the supply lines, enhancing safety and compliance with regulatory standards.

Key Considerations for Check Valve Selection and Installation

When selecting and installing check valves, it's essential to consider factors such as application requirements, pressure ratings, and material compatibility. Check valves, crucial in directing flow within piping systems, must be chosen based on the specific conditions they will face. This includes evaluating the system's pressure and temperature, as well as understanding if the fluid is corrosive. With the growing trend of refineries retooling for sustainable aviation fuel production, it becomes even more vital to ensure that check valves can handle novel processes and materials without compromising functionality.

Installation is equally important; improper fitting can lead to failures or leaks, particularly in high-pressure environments. Before installation, ensure that the valve orientation matches the flow direction, and utilize proper sealing methods to avoid leaks. Regular maintenance, such as inspections for wear and deposits, is necessary to prolong the lifespan of check valves and ensure their continued effectiveness in various applications, including those in energy-intensive systems. By paying close attention to these considerations, engineers can optimize system performance and enhance safety across various industries.

The Essential Guide to Understanding Check Valves

This chart illustrates the distribution of various types of check valves used in different applications. It highlights the prevalence of each type based on industry requirements, aiding in the selection process for users.

Maintenance Best Practices for Prolonging Check Valve Lifespan

Proper maintenance of check valves is crucial for ensuring their longevity and optimal performance in various applications. According to a report by the American Society of Mechanical Engineers (ASME), regular maintenance can extend the lifespan of check valves by up to 50%. This involves periodic inspections to detect signs of wear, corrosion, or any mechanical failures that could compromise their function. Operators should employ a maintenance schedule that includes cleaning, lubrication, and the replacement of worn parts to maintain efficiency and prevent unexpected failures.

In addition, employing best practices such as proper installation techniques and monitoring for backflow conditions can significantly enhance the reliability of check valves. Data from the Hydraulic Institute indicates that about 30% of valve failures stem from improper installation or system pressure anomalies. Ensuring that the check valve is appropriately sized and installed at the correct angle will mitigate such risks. By adhering to these maintenance tips and utilizing data-driven approaches, industries can effectively prolong check valve lifespan, ensuring smooth operation within their systems.

Related Posts

-

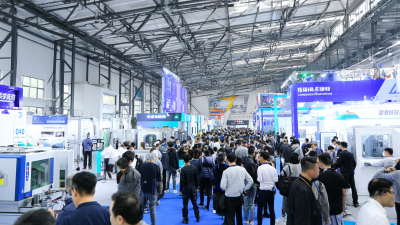

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025

-

7 Best Flange Gasket Options You Didn't Know Existed

-

How to Choose the Right Stainless Steel Ball Valves for Your Application

-

The Future of PVC Parts Revolutionizing Manufacturing and Sustainability

-

The Role of Butterfly Valves in Modern Industry: A Comprehensive Overview

-

5 Key Benefits of Choosing the Right Fittings and Valves for Your Projects