Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Top 2025 Ball Valves Types You Need to Know for Your Projects

When embarking on any engineering or industrial project, understanding the various components is crucial for success. Among these components, ball valves stand out as essential fittings that are widely used across diverse applications. These valves are designed to control the flow of fluids and gases, offering a reliable solution for both high and low-pressure environments. As we move toward 2025, advancements in technology and materials have led to the development of different types of ball valves, each suited for specific requirements and conditions.

This article aims to explore the top ball valve types you need to know for your upcoming projects. From the classic two-piece and three-piece designs to specialized variants like trunnion-mounted ball valves, we'll delve into their features, advantages, and ideal applications. By familiarizing yourself with these types of ball valves, you will be better equipped to make informed decisions that enhance the efficiency, safety, and performance of your projects. Whether you are involved in water treatment, oil and gas, or any other sector utilizing fluid transfer, understanding the latest ball valve technologies will empower you to achieve project success.

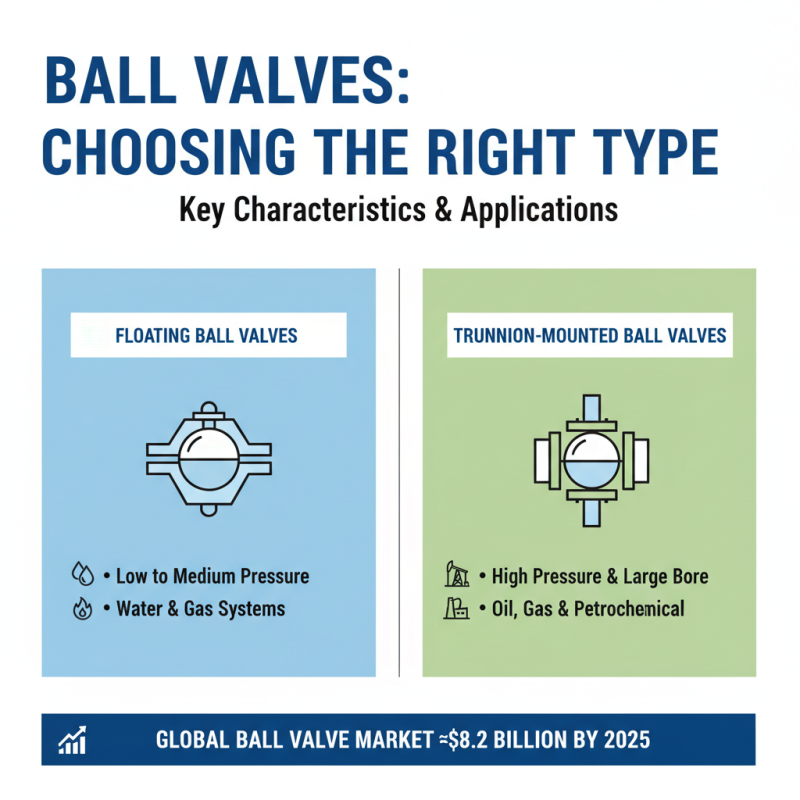

Top 2025 Ball Valve Types: Key Characteristics and Applications

When it comes to choosing the right ball valve for your projects, understanding the key characteristics and applications of different types is essential. In the industry, ball valves are categorized based on their construction, such as floating and trunnion-mounted designs. Floating ball valves are commonly used in low to medium pressure applications, making them ideal for water and gas systems. According to a recent market research report, the global ball valve market is expected to reach approximately $8.2 billion by 2025, highlighting the growing demand for efficient and reliable fluid control solutions in various sectors.

Trunnion-mounted ball valves, on the other hand, are designed for high-pressure applications and large pipeline systems. These valves offer increased stability and reduced friction, making them suitable for critical processes in oil and gas, chemical manufacturing, and power generation industries. A report from the Valve Manufacturer's Association indicates that the adoption of advanced materials and technologies in valve design is anticipated to enhance performance, further driving market growth. Moreover, understanding the specific operational demands of each application will guide engineers and project managers in selecting the most appropriate valve type, ultimately contributing to the effectiveness and safety of their projects.

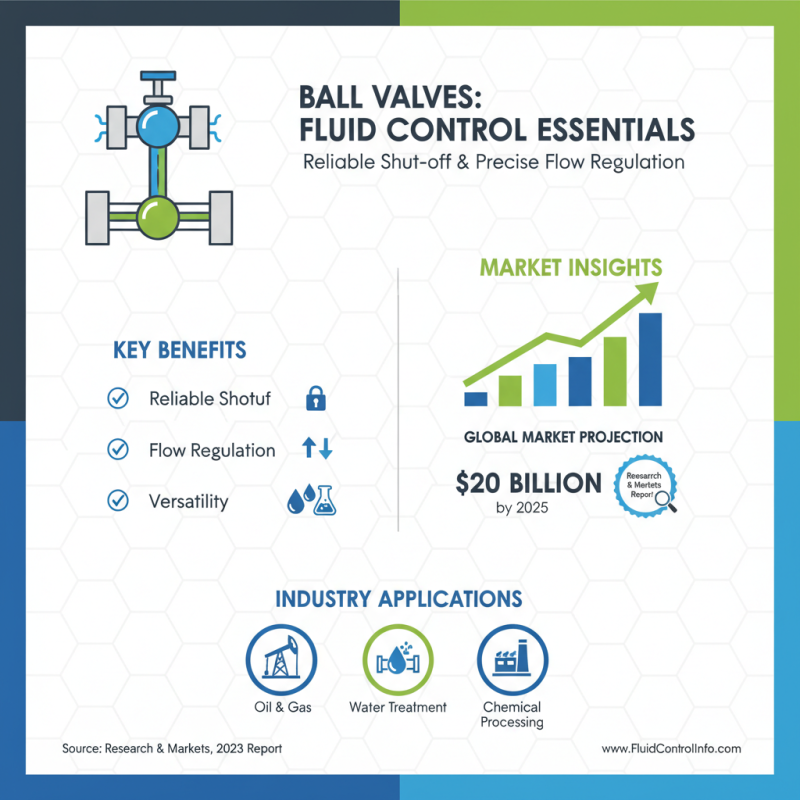

Understanding the Benefits of Different Ball Valves in Fluid Control

Ball valves are essential components in fluid control systems, renowned for their ability to provide reliable shut-off and precise flow regulation. Understanding the benefits of different types of ball valves is crucial for selecting the right one for your projects. According to a report by Research and Markets, the global ball valve market is projected to reach $20 billion by 2025, driven by increasing demand for efficient flow control in various industries, including oil and gas, water treatment, and chemical processing.

Among the various types of ball valves, trunnion-mounted designs are particularly favored for high-pressure applications. They minimize torque and provide greater stability, making them ideal for large-scale operations. A study by MarketsandMarkets found that trunnion ball valves account for approximately 40% of the total ball valve market share, reflecting their prominence in sectors requiring robust and durable solutions. On the other hand, floating ball valves are often utilized in low-pressure systems due to their simpler design and cost-effectiveness. They offer excellent sealing capabilities, making them suitable for applications in pharmaceuticals and food processing, where contamination risks need to be minimized.

In the increasingly stringent landscape of process control, the choice of ball valves can significantly impact operational efficiency and safety. The versatility and reliability of ball valves make them an indispensable choice across various applications. By understanding the unique benefits of each type, engineers and project managers can make informed decisions that enhance fluid control, leading to improved system performance and lower operational costs.

Comparative Analysis of Full-Bore vs. Reduced-Bore Ball Valves

When selecting ball valves for various projects, understanding the differences between full-bore and reduced-bore options is crucial. Full-bore ball valves feature a ball with a hole that aligns perfectly with the pipeline diameter, allowing for unrestricted flow and minimal pressure loss. This makes them particularly suitable for applications where fluid velocity and system efficiency are priorities. Industries such as oil and gas, water treatment, and chemical processing often leverage full-bore designs to optimize performance and reduce energy costs.

In contrast, reduced-bore ball valves have a smaller ball that creates a constriction in the flow path. While these valves may introduce a slight pressure drop, their compact design can be advantageous in systems where space is limited. Reduced-bore valves are often used in applications not as heavily reliant on flow capacity, such as HVAC systems or smaller pipelines. When making a choice between the two types, project requirements—including pressure, flow rate, and spatial constraints—should guide the decision, ensuring the selected valve type aligns with operational needs.

Top 2025 Ball Valves Types You Need to Know for Your Projects - Comparative Analysis of Full-Bore vs. Reduced-Bore Ball Valves

| Valve Type | Diameter (inches) | Flow Capacity (Cv) | Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Full-Bore Ball Valve | 2 | 200 | Water Supply, Gas Distribution | Minimal Pressure Drop, Un obstructed Flow | Higher Costs, Bulkier Design |

| Reduced-Bore Ball Valve | 2 | 150 | Industrial Processes, Chemical Transport | Compact Design, Cost-Effective | Higher Pressure Drop, Limited Flow Capacity |

| Full-Bore Ball Valve | 3 | 300 | Pipelines, HVAC Systems | High Flow Efficiency, Versatile Use | More Expensive, Heavier |

| Reduced-Bore Ball Valve | 3 | 220 | Oil Refining, Water Treatment | Space Saving, Cost Benefits | Reduced Flow, Less Efficiency |

Industry Trends: Innovations in Ball Valve Technology for 2025

As we approach 2025, the landscape of ball valve technology is experiencing significant innovations driven by the need for enhanced efficiency and sustainability in industrial applications. Recent industry reports estimate that the global ball valve market will reach approximately $14 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth is largely due to the increasing demand for advanced valve solutions in the oil and gas, water treatment, and chemical industries, where reliability and precision are paramount.

One of the notable trends is the development of smart ball valves that integrate IoT technology, allowing for real-time monitoring and control. According to a report by MarketsandMarkets, the adoption of smart valves is expected to increase by over 30% in the next few years, reflecting the industry's shift toward automation and data-driven decision-making. These smart systems not only improve operational efficiency but also help mitigate risks, as they can provide immediate alerts on maintenance needs or operational anomalies.

Additionally, innovations in materials are also reshaping the ball valve market. The introduction of lightweight, corrosion-resistant materials, including advanced polymers and composite materials, is leading to more durable and efficient valve solutions. A study by ResearchAndMarkets highlights that these materials reduce the overall weight of valves by up to 25%, which can significantly decrease installation costs and enhance the performance of valve systems across various applications. As we move forward, these technological advancements will be crucial for meeting the evolving demands of industries reliant on high-performance valve systems.

Top 2025 Ball Valves Types You Need to Know for Your Projects

This chart showcases the expected market share of different types of ball valves based on current industry trends and innovations in technology projected for 2025.

Selecting the Right Ball Valve Material: Insights for Optimal Performance

Selecting the right material for ball valves is crucial for ensuring optimal performance in various applications. The material affects not only the valve’s durability but also its resistance to corrosion, temperature fluctuations, and pressure variations. Common materials include stainless steel, brass, and plastic, each offering distinct advantages depending on the specific requirements of the project. Stainless steel is favored for its strength and resistance to rust, making it ideal for high-pressure and high-temperature environments. On the other hand, brass provides excellent resistance to corrosion, which is particularly useful in plumbing applications.

When considering ball valve materials, it's essential to assess the medium they will control. For instance, valves in corrosive environments will benefit from materials with higher resistance, such as specialized plastics or coated metals. Additionally, the working temperature and pressure ratings will dictate the material choice; for lower pressures and temperatures, a plastic valve might suffice, whereas extreme conditions might necessitate a robust metal option. Understanding these factors ensures that the selected ball valve will perform efficiently and have a longer service life, ultimately contributing to the reliability of the overall system.

Related Posts

-

Top 10 Ball Valves for Optimal Performance and Reliability in Your Projects

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

Exploring Innovative Alternatives to Stainless Fittings: Industry Insights and Trends