Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Top 10 Best Valves Fittings for Your Plumbing Needs

In the realm of plumbing, the importance of choosing the right valves fittings cannot be overstated. According to renowned plumbing expert James Thatcher, “The quality and compatibility of valves fittings can make or break the efficiency of a plumbing system.” This insight underscores the critical role these components play in ensuring water flow regulation and preventing leaks, which are common concerns in both residential and commercial installations.

When tackling your plumbing needs, selecting appropriate valves fittings involves understanding various types, their functionalities, and their suitability for specific applications. From ball valves to gate valves, the market offers a plethora of options, each designed to meet different requirements. With the right information, homeowners and professionals alike can navigate these choices effectively, enhancing the durability and performance of their plumbing systems.

This article delves into the top 10 best valves fittings available today, examining their features, benefits, and ideal uses. By equipping yourself with this knowledge, you empower your plumbing projects with solutions that ensure efficiency, reliability, and longevity. Let’s explore the best options in the industry to meet your unique plumbing needs.

Types of Valves and Fittings Commonly Used in Plumbing

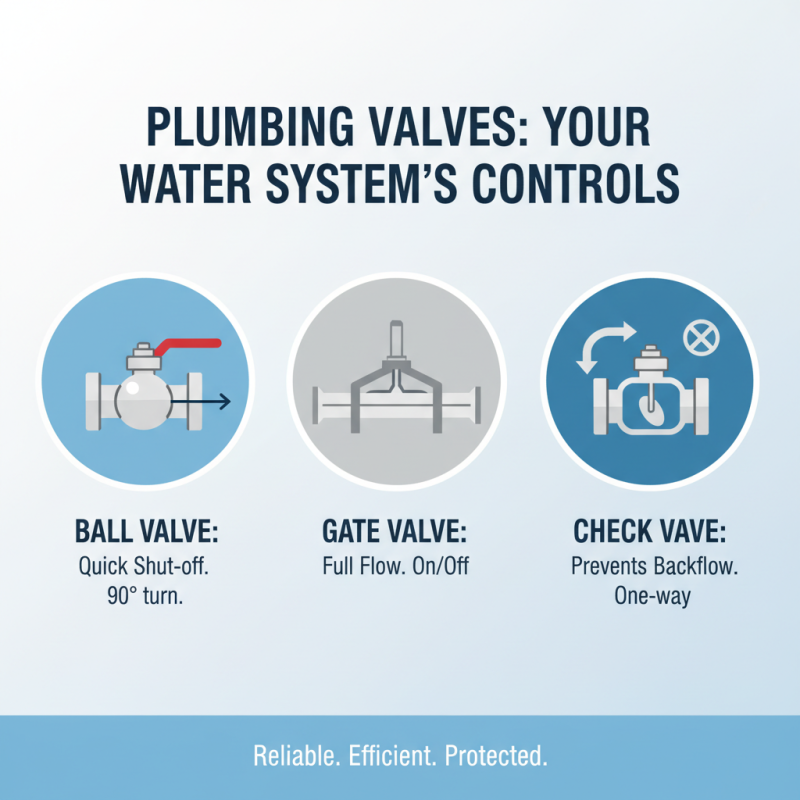

When it comes to plumbing, understanding the different types of valves and fittings is essential for ensuring a reliable and efficient water system. Valves serve as control devices that manage the flow of water through pipes, and they come in various types suited for different applications. Common types include ball valves, which offer quick shut-off, and gate valves, which allow full flow when open. There are also check valves designed to prevent backflow, ensuring that water flows in a single direction, thus protecting your plumbing from potential damage.

Fittings, on the other hand, are crucial for connecting different sections of pipe and altering the direction of flow. Common fittings include elbows, which enable changes in direction, and tees, which allow for the branching out of piping systems. Couplings and reducers serve as connectors, enabling seamless transitions between pipes of different diameters. Together, these valves and fittings form the backbone of any plumbing system, helping to maintain effective water distribution and preventing leaks or other issues. Understanding these components and their functions can greatly simplify plumbing projects and repairs.

Key Features to Consider When Choosing Plumbing Valves

When selecting plumbing valves, understanding key features is crucial for ensuring efficiency and durability. One of the primary factors to consider is the material of the valve. According to a report from the Worldwide Pipe and Valve Marketplace, materials such as brass, stainless steel, and PVC offer varying degrees of corrosion resistance and pressure handling capabilities. Brass valves typically excel in applications where water temperature fluctuates, while stainless steel is preferred for high-pressure settings due to its strength and longevity. PVC, on the other hand, is ideal for non-potable water systems, being cost-effective and resistant to chemical damage.

Another critical feature is the valve’s type and function. The American Society of Plumbing Engineers indicates that different valves serve specific purposes, such as gate valves for on/off control, ball valves for quick shut-off, and check valves to prevent backflow. Each type plays a significant role in maintaining the efficiency of a plumbing system. Additionally, functionalities like pressure rating and temperature tolerance are essential, as they ensure that the selected valve can handle the specific conditions of your plumbing network. Valves not adhering to the required specifications may lead to failures, resulting in costly repairs and potential safety hazards. Therefore, examining these parameters should be a priority when choosing the right fittings for your plumbing needs.

Top 10 Best Valves Fittings for Your Plumbing Needs

Top 10 Recommended Valves for Residential Plumbing Applications

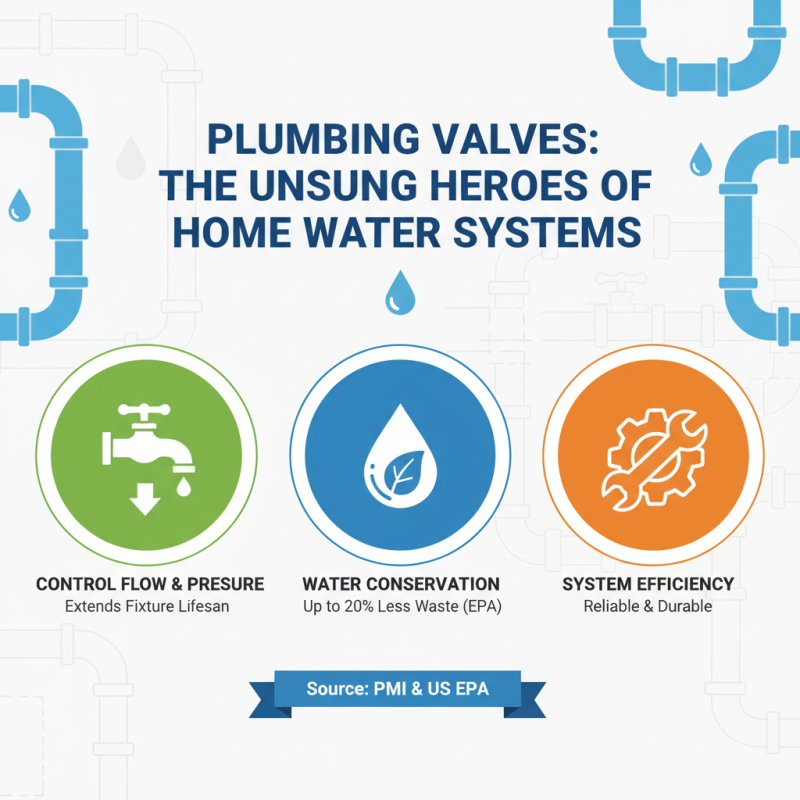

When it comes to ensuring an efficient and functional plumbing system in a residential setting, selecting the right valves is crucial. According to a report by the Plumbing Manufacturers International (PMI), valves are vital components that control the flow and pressure of water in plumbing systems. Their proper functioning not only enhances the lifespan of plumbing fixtures but also contributes significantly to water conservation efforts. In fact, the U.S. Environmental Protection Agency (EPA) estimates that proper valve installation can reduce water waste by up to 20%.

Among the various types of valves available, gate valves, ball valves, and globe valves stand out as top recommendations for residential plumbing applications. Gate valves are prized for their minimal flow resistance when fully opened, making them ideal for main water lines. Ball valves are highly regarded for their durability and ability to provide a tight seal, which makes them perfect for shut-off applications. Globe valves, with their unique design, are excellent for regulating flow and are often used in systems requiring throttling. Research shows that using high-quality valves can lead to a notable decrease in maintenance costs, with some studies indicating savings of over 30% in long-term operations. Thus, selecting the right valves can greatly enhance the efficiency and reliability of your plumbing system.

Best Fittings for Efficient and Leak-Free Plumbing Systems

When it comes to establishing an efficient and leak-free plumbing system, selecting the right valves and fittings is essential. Studies in the plumbing industry reveal that improper fittings can lead to significant water loss, resulting in increased utility bills and potential structural damage. According to a report by the Environmental Protection Agency (EPA), leaks in home plumbing systems can waste over 10,000 gallons of water per year, emphasizing the importance of quality fittings that ensure tight seals and durability under pressure.

To enhance the efficiency of your plumbing system, consider investing in fittings made from materials like brass or CPVC, which are known for their resilience and corrosion resistance. Additionally, the correct sizing and compatibility of fittings with existing pipework are crucial. A mismatch can not only lead to leaks but may also compromise the entire system's integrity. Regular inspections and maintenance can help in identifying wear and tear early, preventing any costly surprises down the road.

Tips: Always measure your pipes before purchasing fittings to avoid sizing issues. Additionally, applying thread sealant can provide extra protection against leaks in threaded connections. When installing valves, ensure they are easily accessible for future repairs, while also maintaining efficiency in the plumbing layout. Consistent checks for signs of moisture around fittings can help you catch leaks before they escalate.

Tips for Maintaining and Installing Valves and Fittings Properly

When it comes to maintaining and installing valves and fittings in your plumbing system, proper techniques are essential for ensuring longevity and functionality. According to a report by the American Society of Plumbing Engineers, improper installation and maintenance can lead to a 30% increase in repair costs over time. This highlights the importance of understanding both the materials and the methods used in valve and fitting installation. Always ensure that you utilize the appropriate tools and techniques, such as using thread sealant on threaded connections and verifying proper torque specifications, which can significantly reduce the risk of leaks.

Regular maintenance is equally crucial. The National Association of Plumbing Contractors recommends periodic inspections and maintenance every 6-12 months, depending on usage and water quality. During these inspections, check for signs of wear, corrosion, or leaks in fittings, and ensure that all connections remain tight. Cleaning valves regularly and ensuring that any moving parts operate freely can also prevent costly failures. By following these guidelines and utilizing proper installation techniques, you can enhance the durability and reliability of your plumbing system, ultimately avoiding unexpected disruptions and expenses.

Related Posts

-

Top Strategies for Sourcing High Quality Steel Fittings

-

How to Choose the Right Flange Valves for Your Plumbing System

-

What is Steel and Fittings A Comprehensive Guide to Types and Uses

-

How to Choose the Right Flange Valves for Your Industrial Needs

-

How to Choose the Right Valves Fittings for Your Plumbing Needs

-

Top 10 Globe Valves: Essential Choices for Optimal Flow Control Solutions