Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

What is Steel Flanges and Their Uses in Industrial Applications?

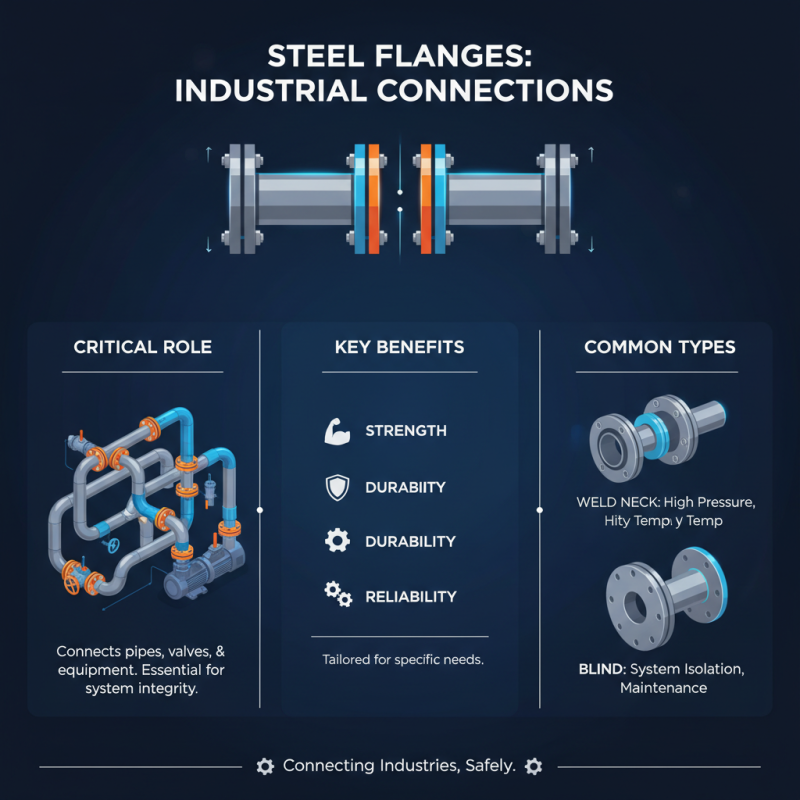

Steel flanges play a crucial role in industrial applications. They enable the connection of pipes, valves, and other equipment. Understanding their significance is vital for anyone involved in manufacturing or construction.

These components are circular pieces of steel, designed to fit onto the ends of pipes. They help create a tight seal, preventing leaks and ensuring system integrity. Different types of steel flanges are available, each serving unique purposes.

In many industries, flanges are essential for maintaining safety and efficiency. Yet, their improper use can lead to serious issues. Choosing the right flange for an application is not always straightforward. Companies must assess their needs carefully. A wrong choice may lead to costly repairs or operational delays. It’s important to reflect on these factors.

Definition and Composition of Steel Flanges

Steel flanges are an essential component in piping systems. They act as connection points for pipes, valves, and other equipment. Generally made from carbon steel or stainless steel, they provide strength and durability. The composition of steel flanges often includes elements like carbon, manganese, and chromium, which enhance their mechanical properties.

In industrial applications, flanges are used in various sectors, such as oil and gas, chemical processing, and water treatment. According to recent market reports, the steel flange market is anticipated to grow by over 5.8% annually from 2021 to 2026. This rise is attributed to increased infrastructure development and industrial activities worldwide.

Tips: Always inspect flanges for quality issues. Consider the pressure ratings when selecting flanges. They must meet specific industry standards.

Flanges can be prone to defects like imperfections or corrosion. Overlooking these flaws can lead to failures. Make sure to prioritize quality control. Proper installation and maintenance are crucial for flanges to perform effectively. Regular checks can prevent costly downtime.

What is Steel Flanges and Their Uses in Industrial Applications? - Definition and Composition of Steel Flanges

| Flange Type | Material Composition | Common Uses | Pressure Ratings | Standards |

|---|---|---|---|---|

| Weld Neck Flange | Carbon Steel, Stainless Steel | Pipelines, Pressure Vessels | Class 150 to Class 2500 | ASME B16.5, ASTM A105 |

| Slip-On Flange | Carbon Steel, Alloy Steel | General Piping | Class 150 to Class 600 | ASME B16.5, ASTM A105 |

| Blind Flange | Carbon Steel, Stainless Steel | End of Piping, Pipe Closures | Class 150 to Class 2500 | ASME B16.5, ASTM A182 |

| Socket Weld Flange | Carbon Steel, Stainless Steel | High-Pressure Applications | Class 300 to Class 600 | ASME B16.5, ASTM A105 |

| Lap Joint Flange | Stainless Steel, Alloy Steel | Vegetable Oil Transport, Pharmaceutical | Class 150 to Class 300 | ASME B16.5 |

Types of Steel Flanges Used in Industry

Steel flanges play a critical role in various industrial applications. They are used to connect pipes, valves, and other equipment in a system. Different types of steel flanges are designed for specific needs, offering unique characteristics and advantages in strength and durability.

Weld neck flanges are common in high-pressure applications. They provide excellent resistance to bending and are often used in sectors like oil and gas. Slip-on flanges are easier to install, making them a popular choice for many industries, despite being less robust than weld neck options. According to industry reports, the demand for weld neck flanges is projected to grow by 7% annually.

Another type is blind flanges, which are used to seal pipe ends. They can withstand high temperatures and pressures. The global market for blind flanges is estimated to be worth over $1 billion as industries seek efficient sealing solutions. However, the installation process can sometimes lead to misalignment issues, raising concerns about potential leaks.

Finally, threaded flanges offer flexibility in installations. They are often used in low-pressure applications. While they are simple to use, their reliability can be lower compared to welded models. It's essential for industries to evaluate their specific needs before selecting the appropriate flange type.

Common Applications of Steel Flanges in Various Sectors

Steel flanges play a crucial role across various industrial sectors. In construction, they connect pipes and valves, ensuring structural integrity. The global flange market reached an estimated value of $8 billion in 2022, with a projected growth rate of 5% annually through 2027. Yet, manufacturers often overlook quality control. This can lead to failures when flanges do not meet necessary standards, resulting in costly downtime.

In the oil and gas sector, reliable flanges facilitate safe transportation of materials. A report by Research and Markets highlighted the importance of flanges in high-pressure systems. Many projects still encounter leaks due to improper installation practices. Such failures can be detrimental, exposing workers to hazardous conditions. Around 20% of accidents in this field are linked to equipment failures, often tied to flange issues.

The chemical industry also relies heavily on steel flanges. They secure pipelines that transport corrosive substances. Industry data shows that improper material selection can lead to severe consequences, including chemical spills. More than 30% of these incidents stem from flange fatigue or corrosion. Despite advancements, regular inspections are frequently neglected, raising safety and environmental concerns.

Common Applications of Steel Flanges in Various Sectors

Advantages of Using Steel Flanges in Industrial Settings

Steel flanges play a vital role in various industrial applications. They create secure connections between pipes, valves, and other equipment. This reliability is crucial in maintaining the integrity of piping systems.

One significant advantage of using steel flanges is their strength. They can withstand high pressures and temperatures. This robustness is essential for industries such as oil and gas, where the stakes are high. Corrosion resistance is another key benefit. When properly coated, steel flanges resist rust and degradation. This durability extends their lifecycle, saving costs on replacements.

However, it's important to consider some challenges. Proper installation is critical. Misaligned flanges can lead to leaks. Regular inspections are necessary to avoid potential failures. Making good choices about materials and coatings is essential. While steel flanges offer many benefits, they require thoughtful implementation in any industrial setting.

Maintenance and Safety Considerations for Steel Flanges

Steel flanges play a crucial role in many industrial systems. However, their maintenance is often overlooked. Regular inspections are essential. They help identify wear, corrosion, and other potential issues. These inspections can prevent unexpected failures. Using proper cleaning methods is important. Residue and contaminants can cause serious problems.

Safety is another key consideration when working with steel flanges. Ensure that connections are tight and secure. Loose flanges can lead to leakage and pressure loss. Always check the torque specifications outlined during installation. This helps maintain the integrity of the system. It is wise to conduct regular training for staff. Familiarizing workers with safety procedures can reduce accidents.

In some cases, flanges may need replacement. Choosing the right type is critical. Not all flanges fit every application. Size, material, and pressure ratings must be considered. When in doubt, consult with experts. This can save time and costs in the long run. Unconsidered decisions may lead to system failures. Reflecting on past experiences is crucial for continual improvement.

Related Posts

-

Comparative Analysis of Steel Flanges: Key Specifications & Market Trends for Global Buyers

-

The Ultimate Guide to Understanding Steel Flanges: Types, Uses, and Industry Insights

-

Unlocking the Advantages of Custom Steel Flanges for Your Next Project: A Comprehensive Guide

-

Ultimate Checklist for Choosing the Right Flanges and Fittings for Your Project

-

Exploring the Rise of Steel Flanges in 2025 China Import Export Trends at the 138th Canton Fair

-

Top Stainless Steel Weld Fittings: A Comprehensive Buying Guide