Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

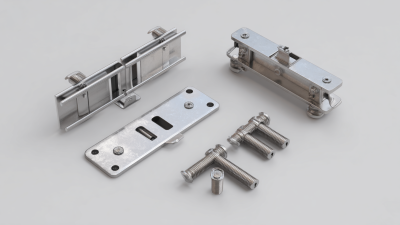

Why Stainless Steel Weld Fittings Are Essential for Modern Industrial Applications

In the contemporary industrial landscape, the significance of stainless steel weld fittings cannot be overstated. According to a recent market analysis by Research and Markets, the global stainless steel fittings market is projected to reach USD 15.2 billion by 2027, driven by the increasing demand for durable and corrosion-resistant materials across various sectors, including construction, oil and gas, and chemical processing.

Stainless steel weld fittings are pivotal in ensuring the integrity and safety of piping systems, providing superior strength and resistance to harsh environments. As industries aim to enhance operational efficiency and reduce maintenance costs, the adoption of stainless steel weld fittings stands as a critical component in modern manufacturing and infrastructure projects.

Emphasizing their essential role not only highlights the advances in material technology but also underscores their importance in meeting stringent regulatory standards, making them an indispensable asset for any industrial application.

The Importance of Stainless Steel Weld Fittings in Industrial Settings

In modern industrial settings, the integration of stainless steel weld fittings is vital for ensuring both safety and efficiency. According to a report by MarketsandMarkets, the global stainless steel market in industrial applications is expected to reach $200 billion by 2025, with a significant portion attributed to the demand for high-quality weld fittings. These fittings guarantee the integrity of piping systems, preventing leaks and minimizing the risk of contamination, which is crucial in industries such as pharmaceuticals and food processing.

Furthermore, the durability and corrosion resistance of stainless steel make it an ideal choice for various environments. A study published in the International Journal of Industrial Engineering highlights that stainless steel components can withstand extreme temperatures and harsh chemicals, reducing the need for frequent replacements. This longevity not only lowers maintenance costs but also enhances operational reliability, making stainless steel weld fittings a prudent investment for any industrial application. In essence, the choice to utilize stainless steel weld fittings is a strategic decision that aligns with the growing emphasis on safety and operational efficiency in today’s industrial landscape.

Key Characteristics of Stainless Steel for Weld Fitting Applications

Stainless steel weld fittings play a crucial role in various industrial applications due to their unique characteristics, which include exceptional corrosion resistance, high strength, and durability. According to a report by MarketsandMarkets, the global stainless steel market is projected to reach $157.3 billion by 2026, highlighting the growing reliance on stainless steel in construction, automotive, and chemical processing industries. The material's ability to withstand harsh environments makes it particularly valuable in sectors such as oil and gas, where equipment is often exposed to corrosive substances.

One of the key characteristics of stainless steel that makes it suitable for weld fitting applications is its resistance to oxidation and staining. For instance, Type 316 stainless steel contains molybdenum, which enhances its resistance to chlorides, a common cause of pitting in harsher environments. The American Welding Society (AWS) notes that proper welding techniques utilizing stainless steel fittings can achieve high joint strength while minimizing the risk of corrosion, making these fittings an integral part of maintaining the integrity of piping systems. Furthermore, the flexibility of stainless steel allows for various welding methods, ensuring compatibility with numerous industrial processes.

Common Applications of Stainless Steel Weld Fittings in Industry

Stainless steel weld fittings play a crucial role in various industrial applications due to their strength, durability, and resistance to corrosion. In sectors such as petrochemicals, food processing, and pharmaceuticals, these fittings are essential for maintaining the integrity of pipe systems. For instance, in the food and beverage industry, stainless steel fittings ensure that the transport of products is hygienic and free from contamination, while their ability to withstand high temperatures and pressures makes them ideal for chemical processing.

Additionally, the versatility of stainless steel weld fittings makes them indispensable in construction and infrastructure projects. They are commonly employed in HVAC systems and water supply networks, where their robust nature prevents leaks and failures in critical pathways. Furthermore, as industries increasingly demand sustainable materials, stainless steel's recyclability enhances the appeal of using these fittings, making them an environmentally friendly choice for modern industrial applications.

Benefits of Using Stainless Steel Over Other Materials in Welding

Stainless steel has become the material of choice for weld fittings in modern industrial applications, primarily due to its superior properties compared to alternatives such as carbon steel or plastic. According to a report by the Global Stainless Steel Market Research Institute, the demand for stainless steel in industrial applications is projected to grow at a CAGR of 6.5% through 2025. This is largely attributed to its exceptional corrosion resistance, which makes it ideal for environments that expose materials to moisture and chemicals, thus ensuring longevity and reducing maintenance costs.

In addition to corrosion resistance, stainless steel offers superior strength and durability. In a study from the American Institute of Steel Construction, it's noted that stainless steel can withstand extreme temperatures and pressures, making it suitable for high-stakes environments like oil and gas pipelines and pharmaceutical manufacturing. Furthermore, its hygienic properties make it a preferred choice in food processing industries, where cleanliness is paramount. With its resilience and reliability, stainless steel truly stands out as a leading material in welding, providing both safety and efficiency across various sectors.

Best Practices for Selecting and Installing Stainless Steel Weld Fittings

When selecting and installing stainless steel weld fittings for modern industrial applications, it's crucial to consider the material's inherent properties and the specific operational demands. Stainless steel's corrosion resistance, longevity, and cost-effectiveness make it a preferred choice across various industries, from automotive to construction. According to industry reports, nearly 70% of engineers prioritize material durability when evaluating welding fittings, which underlines the significance of incorporating high-quality stainless steel in design specifications.

When it comes to installation best practices, attention to detail is essential. Proper welding techniques are vital to ensure the integrity and longevity of the fittings. Recent advancements, such as the optimization of laser welding processes using Machine Learning, demonstrate how data-driven approaches can enhance weld quality while minimizing errors. Reports suggest that employing these cutting-edge techniques can improve process efficiency by up to 30%. Additionally, ensuring compliance with safety standards during installation helps mitigate risks associated with improper fitting, a concern echoed by experts in the field, emphasizing that workplace safety should always be prioritized.

Related Posts

-

Comparative Analysis of Steel and Fittings: Selecting the Best Options for Global Buyers

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

How to Select the Right Gate Fittings for Your Project

-

How to Choose the Right Floating Ball for Your Industrial Applications

-

The Future of PVC Parts Revolutionizing Manufacturing and Sustainability

-

How to Choose the Right Stainless Valves for Your Industrial Applications