Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

Top Stainless Steel Valves Types and Their Applications?

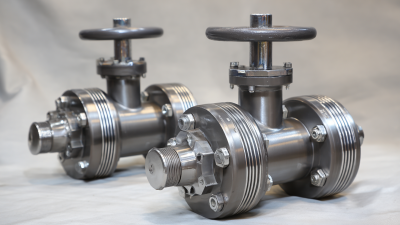

Stainless steel valves are crucial in various industries. They are known for their durability and corrosion resistance. According to a recent market report by Grand View Research, the global stainless steel valves market is expected to reach USD 11.4 billion by 2025. This growth highlights the increasing demand in sectors such as oil and gas, water treatment, and food processing.

Different types of stainless steel valves serve distinct purposes. Gate, ball, and check valves are commonly used across industries. Each type has unique benefits, yet their selection can be challenging. For example, while gate valves provide low friction loss, they may not be ideal for applications requiring quick shut-off. This complexity demands careful consideration.

The variety of stainless steel valves reflects the complexities in industrial applications. They must meet specific standards and regulations. Balancing performance and compliance can be difficult. Selecting the right type of valve requires understanding both technical specs and operational needs. There is still much to learn about optimizing stainless steel valves for various environments.

Types of Stainless Steel Valves and Their Key Characteristics

Stainless steel valves come in several types, each with unique characteristics suited for various applications.

Ball valves are popular for their excellent sealing abilities and quick operation. They are often used in oil and gas applications.

Gate valves, on the other hand, offer minimal flow resistance. They are widely found in water supply systems.

The durability of stainless steel valves is a major advantage. They resist corrosion and maintain reliability even in extreme conditions. However, users should note that not all stainless steel grades are the same.

Some may not withstand highly acidic environments. It is important to choose the right grade based on the specific application.

Tip: Always consider the operating pressure and temperature when selecting a valve. A mismatch could lead to premature failure.

Another type, check valves, allow flow in one direction only. They prevent backflow, making them essential in many industrial processes.

However, the installation position matters; improper setup can hinder performance.

Tip: Regular maintenance can extend the life of stainless steel valves. Inspect seals and connections to avoid leaks.

Applications of Stainless Steel Valves in Various Industries

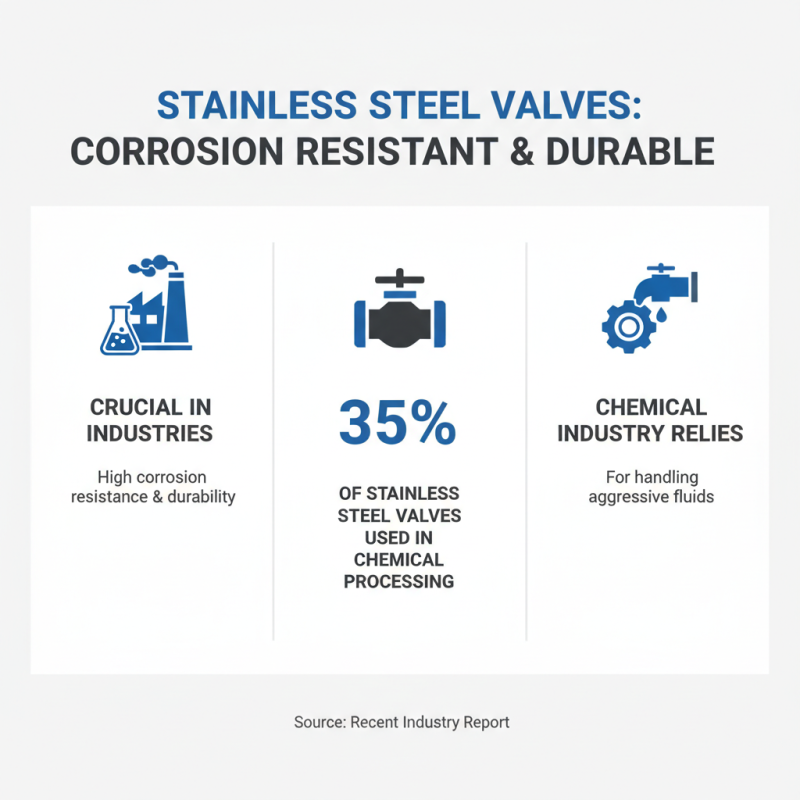

Stainless steel valves are crucial in multiple industries. They excel in environments that require high corrosion resistance and durability. The chemical industry often relies on these valves for handling aggressive fluids. In fact, a recent industry report indicated that about 35% of stainless steel valves are used in chemical processing plants.

In the oil and gas sector, their applications are equally significant. Stainless steel valves can withstand extreme pressures and temperatures. Research shows that more than 60% of pipelines utilize these valves to maintain safety and efficiency. However, their cost can be a barrier for smaller operations. This creates a gap in accessibility for essential maintenance.

Water treatment facilities also heavily utilize stainless steel valves. They ensure clean water supply and management. Studies suggest that these valves can extend the lifecycle of treatment plants by 20%. Yet, installation mistakes can lead to costly leaks. Such errors highlight the importance of proper training and inspection in this field.

Comparative Analysis of Common Stainless Steel Valve Designs

When considering stainless steel valves, various designs cater to diverse applications.

Gate valves

are known for their durability and strength. They work well in on/off applications. Often used in industries,

they may struggle with throttling. Proper installation can mitigate common issues.

Ball valves offer quick shut-off capabilities.

They are versatile and widely used across sectors. However, their sealing surfaces can wear out over time.

Regular maintenance is vital to ensure longevity.

Butterfly valves are lightweight and easy to install. They are often chosen for large volume applications.

Yet, they may not provide tight sealing in low-pressure situations.

Check valves prevent backflow and are crucial in plumbing. These valves can fail if debris accumulates.

Routine checks can help avoid complications. Overall, each type of stainless steel valve has unique strengths and weaknesses.

Understanding these differences is key to application success.

Impact of Stainless Steel Grades on Valve Performance

The choice of stainless steel grades significantly impacts valve performance. Different grades exhibit varying strengths, corrosion resistance, and temperature tolerances. For instance, 304 stainless steel is popular for its good corrosion resistance but may not withstand extreme temperatures. Meanwhile, 316 stainless steel is preferred in environments exposed to corrosive agents. This can be critical in applications like chemical processing where safety is paramount.

Also, the composition of stainless steel affects durability. Variations in nickel, chromium, and molybdenum content alter performance characteristics. Higher nickel content can enhance ductility, while molybdenum improves resistance to pitting corrosion. However, the cost of high-grade steel can be a drawback for many projects. Balancing durability and budget is often a challenge.

Ultimately, the right grade must align with specific operational needs. Engineers should evaluate environmental factors and the intended application before making a selection. Sometimes, compromises are necessary. A less expensive grade may suffice, yet could lead to unforeseen maintenance issues later. It's crucial to weigh these decisions carefully.

Top Stainless Steel Valves Types and Their Applications

| Valve Type | Applications | Stainless Steel Grade | Performance Characteristics |

|---|---|---|---|

| Ball Valve | Oil and Gas, Water Supply | 304, 316 | Low torque, excellent sealing |

| Gate Valve | Pipeline Isolation | 304, 316L | Minimal pressure drop, good corrosion resistance |

| Globe Valve | Flow Regulation | 316, 321 | Good throttling capability, high strength |

| Check Valve | Preventing Backflow | 304L, 316Ti | Automatic operation, reliable sealing |

| Butterfly Valve | Large Volume Flow Control | CF8M, CF3M | Quick operation, lightweight design |

Future Trends in Stainless Steel Valve Technology and Usage

The future of stainless steel valve technology is promising. Industry reports indicate a shift towards smart valves, integrating IoT technology. This allows for real-time monitoring and predictive maintenance. As per a market analysis, the smart valve market is expected to grow by over 10% annually. Manufacturers are focusing on enhancing durability and efficiency, aiming for longer life spans than current models.

Applications in the water treatment and oil and gas industries are expanding. Smart valves can optimize flow control, reducing energy costs. However, there are challenges. Integration with existing systems can be complex. Training staff to use new technologies also poses difficulties. Some companies are still hesitant to adopt these advancements, fearing high upfront costs.

Sustainability is another key trend. Manufacturers are now exploring eco-friendly materials alongside stainless steel. The goal is to minimize environmental impact. In a recent study, around 30% of companies reported investing in sustainable valve solutions. This indicates a shift in focus, though many still rely on traditional materials. Challenges in balancing cost with sustainability remain. The industry must address these issues to fully embrace future trends.

Top Stainless Steel Valves Types and Their Applications

This chart displays the application percentages of various types of stainless steel valves, highlighting their relevance in different industries.

Related Posts

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

-

The Essential Guide to Understanding Check Valves: Types, Applications, and Maintenance Tips

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

What Are Gate Valves and How Do They Work?