Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

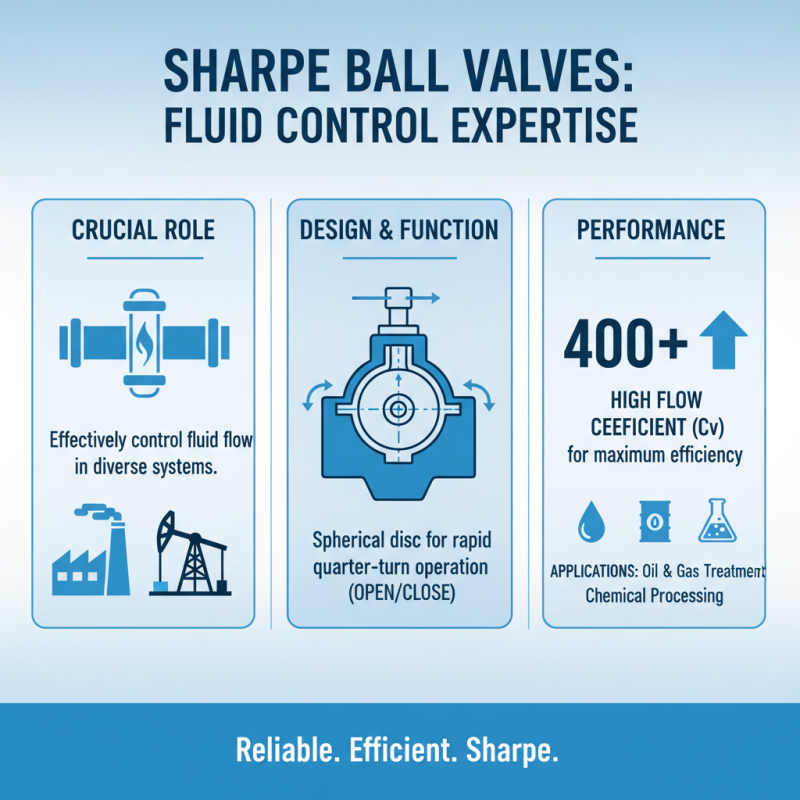

Why Are Sharpe Ball Valves Essential for Efficient Fluid Control?

In industries ranging from oil and gas to water treatment, efficient fluid control is paramount. Sharpe ball valves play a crucial role in this process. According to a recent market report, the global ball valve market is projected to grow significantly, reaching USD 15 billion by 2025. This growth reflects the increasing demand for reliable fluid management solutions.

Sharpe ball valves are known for their durability and precision in controlling flow. They can handle various fluids under different pressure and temperature conditions. For example, in the chemical processing industry, they help minimize leaks and ensure safe operations. However, not all ball valves are created equal. Some industries still struggle with valve failures, leading to downtime and costly repairs.

Choosing the right valve can be overwhelming due to the plethora of options available. Factors such as material compatibility and design specifications can complicate decisions. This highlights the need for proper evaluation and understanding of Sharpe ball valves. By improving versatility and performance, these valves can enhance operational efficiency and reduce risks associated with fluid control.

Understanding the Basics of Sharpe Ball Valves in Fluid Systems

Sharpe ball valves play a crucial role in fluid systems. These valves are designed to control the flow of fluids effectively. Their functionality hinges on a spherical disc, which allows rapid opening and closing. According to industry data, ball valves can achieve flow coefficient values over 400. This efficiency makes them suitable for various applications, from oil and gas to water treatment.

A significant advantage of Sharpe ball valves is their durability. They typically handle pressures exceeding 1000 psi. With proper maintenance, these valves can last for decades. However, inadequate maintenance may lead to sealing failures. This can compromise fluid systems and result in costly downtime. In fact, studies show that 15% of valve malfunctions stem from poor maintenance practices, highlighting the need for vigilance.

Another notable feature is their versatility. They are suitable for both high and low flow rates. Yet, choosing the right valve still requires attention to detail. Not all applications benefit from a ball valve. Sometimes, a globe valve or gate valve might be more effective. Understanding the nuances of fluid systems remains essential for optimized performance.

The Role of Sharpe Ball Valves in Regulating Flow and Pressure

Sharpe ball valves play a significant role in regulating flow and pressure within various systems. These valves provide precise control over liquids and gases, making them essential in many applications. When fluid flows through the valve, it can be easily adjusted with a simple quarter-turn action. This feature allows for rapid response to changing system demands.

In industries like oil and gas or water treatment, efficient flow regulation is crucial. Improper control can lead to leaks or pressure drops, which are both costly and dangerous. The design of the ball valve ensures minimal turbulence. This results in reduced energy loss and increased efficiency. However, achieving the perfect balance can be challenging. Sometimes, minor adjustments can lead to significant changes in system performance.

Maintenance and monitoring are vital for optimal functioning. A neglected valve might not perform as expected. This can create inefficiencies or unexpected failures. Operators must regularly check for wear and tear. Even the slightest degradation can impact flow control. Understanding the valve's role can enhance overall system reliability and efficiency.

Flow Rate and Pressure Regulation with Sharpe Ball Valves

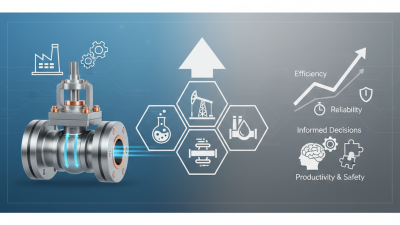

Key Benefits of Using Sharpe Ball Valves for Industrial Applications

Sharpe ball valves play a crucial role in efficient fluid control for industrial systems. These valves are designed to minimize pressure drop, ensuring optimal flow rates. According to a recent industry report, facilities using high-performance ball valves can reduce energy consumption by up to 30%. This significant savings can lead to lower operational costs over time, making them a smart investment for many businesses.

One key benefit of Sharpe ball valves is their excellent durability. They can handle high pressure and temperature fluctuations common in industrial environments. These valves require less maintenance than traditional counterparts. A study revealed that regular maintenance schedules could be extended by up to 20% when using ball valves. Fewer breakdowns mean more uptime, contributing to overall efficiency.

Tip: Always consider the material compatibility. Choosing the right valve material can prevent costly failures. Pay attention to the fluid's chemical properties. Evaluate your specific application needs before purchasing. A well-informed decision can save money and enhance performance. Keep in mind that while ball valves excel at many tasks, they may not be suitable for all applications. Assess your situation carefully to avoid potential issues later.

Comparing Sharpe Ball Valves with Other Valve Types for Fluid Control

When it comes to fluid control, different valve types present unique advantages. Sharpe ball valves stand out for their efficiency and reliability. Unlike gate or globe valves, which can create flow restrictions, ball valves provide a direct flow path. This characteristic minimizes pressure drops and ensures smoother fluid transport.

In a comparison with butterfly valves, ball valves generally offer a tighter seal. This prevents leakage, which is crucial in critical applications. However, the initial investment in ball valves can be higher. Some users might find the upfront costs daunting. Yet, over time, the maintenance savings and reduced energy usage can outweigh those initial expenses.

Additionally, operational simplicity is another dimension. Ball valves can be easily operated by a simple quarter turn. This feature allows for quick shut-off and is especially valuable in emergency situations. On the flip side, selecting the wrong size or type can lead to inefficiencies. It’s essential to consider the specific application to avoid costly mistakes that might arise from improper choices. Each valve type has a purpose—it’s about finding the right fit.

Comparison of Sharpe Ball Valves with Other Valve Types for Fluid Control

| Valve Type | Flow Efficiency | Pressure Rating | Maintenance | Cost Effectiveness |

|---|---|---|---|---|

| Sharpe Ball Valve | High | 1500 PSI | Low, minimal upkeep | Moderate |

| Gate Valve | Medium | 2000 PSI | Moderate, regularly requires service | Low |

| Globe Valve | Medium | 1500 PSI | High, frequent maintenance | High |

| Butterfly Valve | Low | 100 PSI | Low, simple design | Very low |

Maintenance Practices to Ensure Optimal Performance of Sharpe Ball Valves

Maintaining Sharpe ball valves is crucial for fluid control efficiency. Regular inspection is a must. It reduces the risk of leaks and failures. According to industry reports, improper maintenance can lead to efficiency drops of up to 30%. This can severely impact operational costs.

Cleaning is essential. Dust and debris accumulate over time. This buildup can hinder valve operation. Consider implementing a routine cleaning schedule. Inspect seals and gaskets during each check. Reported failures often stem from worn components. In fact, a study revealed that over 40% of valve failures result from these minor issues.

Monitoring valve performance is equally important. Installing pressure gauges provides real-time data. This helps identify irregularities early. A lack of awareness can cost businesses significantly. The financial impact of valve failure is estimated at $1 million annually in some industries. Regular training for maintenance staff can help. Diverse challenges exist in fluid control, but addressing them can ensure optimal performance.

Related Posts

-

Why Choose Sharpe Ball Valves for Your Industrial Applications and Needs

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

How to Choose the Right Sharpe Ball Valves for Your Needs?

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

Discover the Benefits of Using Sharpe Ball Valves for Your Industrial Applications

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs