Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

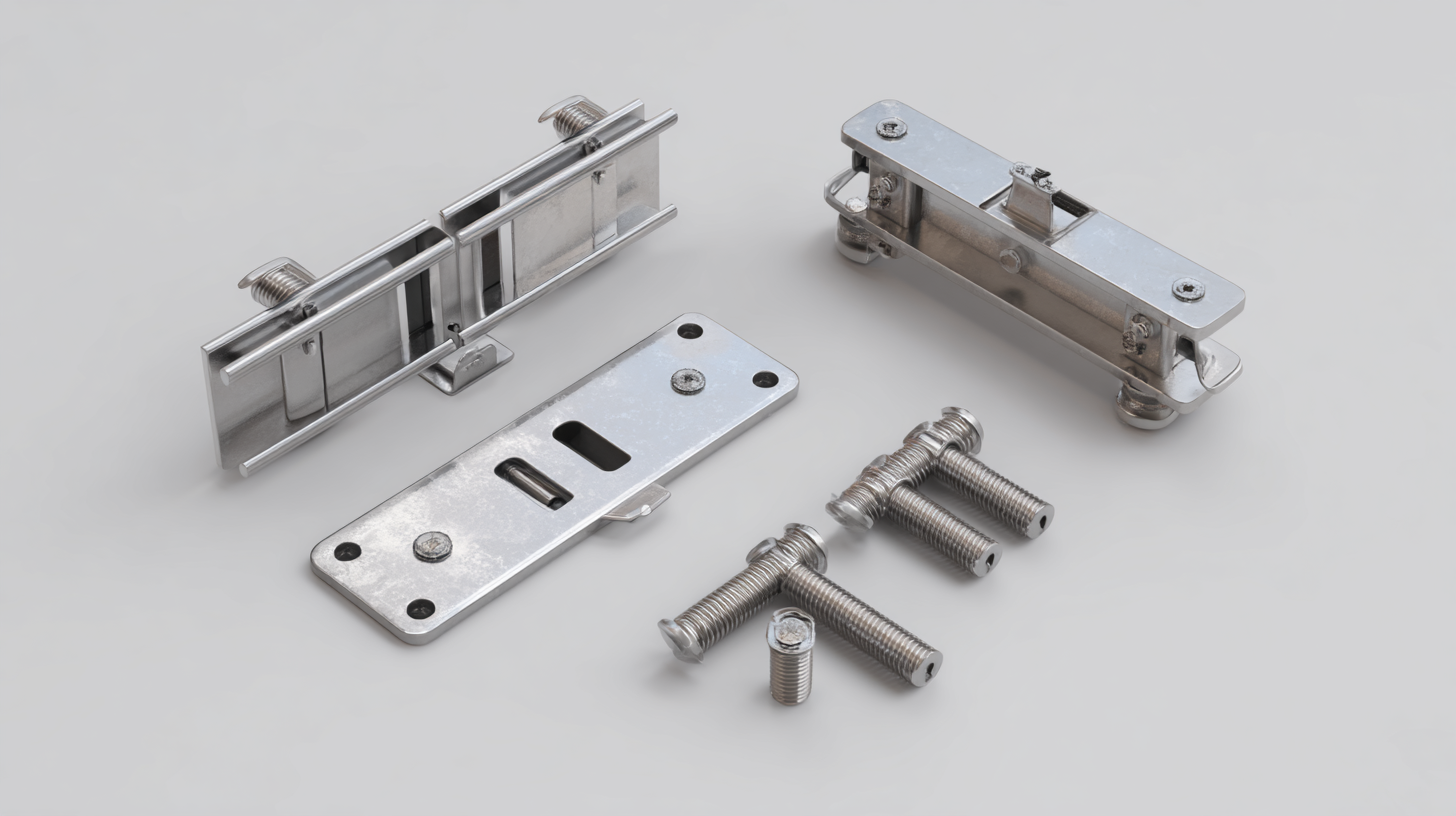

How to Select the Right Gate Fittings for Your Project

Selecting the right gate fittings for your project is crucial to ensure both functionality and aesthetic appeal. Gate fittings are essential components that not only enhance the performance of gates but also contribute to the overall safety and security of a property. With a multitude of options available on the market, from hinges and latches to locks and decorative elements, making the right choice can be daunting. Understanding the specific requirements of your gate, such as size, weight, and intended use, is key to selecting the appropriate fittings. Additionally, considering factors like material compatibility, weather resistance, and design style will help you achieve a cohesive look while ensuring durability. In this guide, we will explore the critical aspects to contemplate when choosing gate fittings for your project, enabling you to make informed decisions and elevate your gate’s functionality and charm.

Evaluating Material Durability: Choosing Between Steel, Aluminum, and Vinyl Fittings

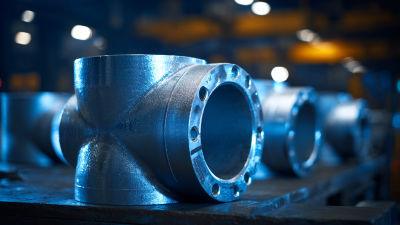

When selecting gate fittings for your project, it is crucial to evaluate the durability of the materials at your disposal. Steel fittings are renowned for their strength and resilience. According to a report by the American Iron and Steel Institute, steel can withstand extreme weather conditions and heavy loads, making it an ideal choice for security gates and high-traffic areas. However, it is prone to rust if not properly coated or maintained, which can be a significant consideration in particularly humid or coastal environments.

On the other hand, aluminum fittings offer a lightweight alternative without sacrificing durability. The Aluminum Association notes that aluminum naturally develops a protective oxide layer, making it resistant to corrosion and reducing maintenance costs significantly over time. This makes aluminum a preferred choice for decorative gates or residential applications where aesthetics matter. Vinyl fittings, while offering excellent resistance to fading and moisture, may lack the strength required in more demanding applications. According to the Vinyl Siding Institute, vinyl is ideal for low-maintenance projects but may not withstand heavy impacts compared to steel or aluminum options. Thus, understanding the specific demands of your project will guide you in selecting the most appropriate material for gate fittings.

Understanding Load-Bearing Capacities: Selecting Fittings for Heavy vs. Light Gates

When selecting gate fittings, understanding load-bearing capacities is crucial, especially when distinguishing between fittings for heavy and light gates. Heavy gates require fittings that can withstand greater stress and weight, ensuring stability and longevity. Typically, robust materials such as stainless steel or heavy-duty galvanized components are recommended. These fittings should be designed to handle the dynamic forces that come into play when the gate is in use, which includes factors like wind resistance and frequent operation.

On the other hand, light gates, such as those made from aluminum or vinyl, necessitate different considerations. The fittings for these gates should be lightweight yet durable enough to provide adequate support without over-engineering the system. Choosing fittings that offer easy installation and allow for some flexibility can significantly enhance the functionality of a light gate while maintaining aesthetic appeal. Understanding the specific requirements of your gates based on their weight and usage will help ensure you select the appropriate fittings for a successful installation.

Assessing Corrosion Resistance: Importance of Coatings and Material Selection

When selecting gate fittings for your project, assessing corrosion resistance is crucial. Corrosion can significantly shorten the lifespan of fittings and negatively affect their functionality. According to a study conducted by the National Association of Corrosion Engineers (NACE), corrosion costs the U.S. economy an estimated $276 billion annually, highlighting the importance of choosing materials and coatings that offer robust protection.

Selecting the right materials involves evaluating the environment in which the fittings will be used. For outdoor applications frequently exposed to moisture and salts, stainless steels with higher alloy content or specialized coatings such as galvanization are often preferable. The American Galvanizers Association reports that hot-dip galvanizing can provide up to 70 years of protection for steel in certain environments. Similarly, powder coatings can enhance both aesthetic qualities and resistance to environmental factors, with their lifespan often exceeding that of traditional liquid coatings. Making informed decisions about material selection and protective coatings not only ensures the durability of gate fittings but also enhances the overall integrity of your project.

Corrosion Resistance of Different Gate Fittings Materials

This chart presents the corrosion resistance levels of various materials typically used in gate fittings. Understanding these materials' performance is crucial for selecting the right fittings for your project.

Identifying Key Fitting Types: Hinges, Latches, and Locks for Optimal Functionality

When selecting gate fittings for your project, understanding the key fitting types—hinges, latches, and locks—is essential for ensuring optimal functionality. Hinges come in various styles, including strap, tee, and continuous hinges, each designed for different types of gates and environments. The choice of hinge affects the gate's weight distribution and ease of movement. For instance, a heavy wooden gate may require robust strap hinges to prevent sagging, while lighter gates might use simple butt hinges for a smooth operation.

When selecting gate fittings for your project, understanding the key fitting types—hinges, latches, and locks—is essential for ensuring optimal functionality. Hinges come in various styles, including strap, tee, and continuous hinges, each designed for different types of gates and environments. The choice of hinge affects the gate's weight distribution and ease of movement. For instance, a heavy wooden gate may require robust strap hinges to prevent sagging, while lighter gates might use simple butt hinges for a smooth operation.

Latches and locks play crucial roles in the gate's security and usability. A reliable latch not only keeps the gate closed but also allows for easy operation from either side. There are various types of latches, such as sliding, bar, and spring-loaded options, each suited for specific functionalities and accessibility needs. Locks, on the other hand, provide an additional layer of security, with choices ranging from padlocks to more sophisticated electronic locking systems. By carefully considering these key fitting types, you can create a gate system that meets both practical needs and enhances the aesthetic appeal of your project.

Matching Aesthetics and Functionality: Integrating Design with Gate Fitting Choice

When selecting gate fittings for a project, balancing aesthetics and functionality is crucial. According to a report by Statista, the global market for gates and gate fittings is projected to reach approximately $12 billion by 2025, indicating a growing demand for both visually appealing and durable options. The design of the gate fittings can significantly enhance the overall appearance of a property while ensuring security and ease of use. For example, decorative hinges and latches can add character to a modern design without sacrificing sturdiness or reliability.

Functional aspects should not be overlooked in the pursuit of aesthetic appeal. A study by IBISWorld highlights that the right fittings can reduce maintenance costs by up to 20% over time. Choosing materials that withstand weather elements not only improves durability but also supports long-term investment. For instance, selecting stainless steel or aluminum fittings can offer corrosion resistance, making them ideal for outdoor gates in various climates. By integrating thoughtful design with robust functionality, gate fittings can ultimately align with the project's goals, transforming outdoor spaces into both visually striking and practical areas.

Related Posts

-

Comparative Analysis of Steel and Fittings: Selecting the Best Options for Global Buyers

-

Exploring Innovative Alternatives to Stainless Fittings: Industry Insights and Trends

-

Common Issues Faced When Sourcing Globe Valves for Your Industrial Needs

-

7 Best Flange Gasket Options You Didn't Know Existed

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

What Are Weld Fittings? Exploring Their Types and Industry Applications with Key Data Insights