Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

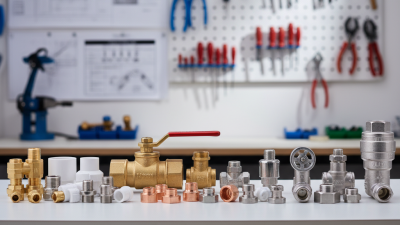

2026 How to Choose Valves Fittings for Your Project?

Choosing the right valves fittings for your project is crucial. According to John Smith, a leading expert in the valves fittings industry, “Quality fittings can prevent costly failures.” Selecting the wrong fittings may lead to leaks and equipment damage.

Consider your project’s specific needs. Are you dealing with high pressure or corrosive materials? These factors influence your choice. It's important to evaluate materials and compatibility. Sometimes, people overlook these details, resulting in poor performance.

Remember that not all valves fittings are created equal. Another expert insight is the importance of certifications. You should always check for industry standards. Even minor mistakes can cause major issues. Reflect on your choices and ensure they align with your project's goals.

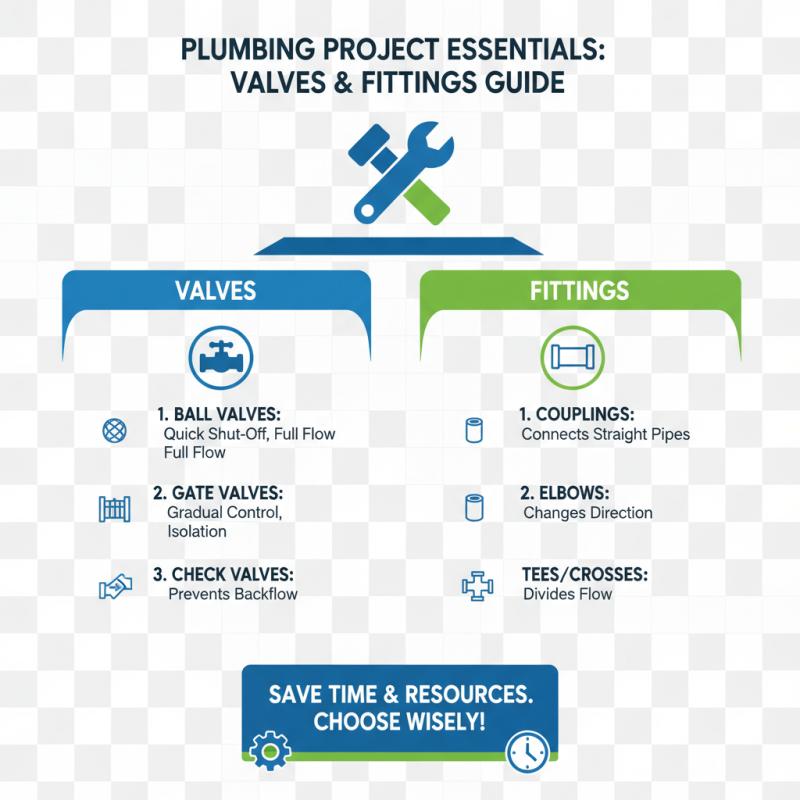

Understanding Different Types of Valves and Fittings in Plumbing Projects

Choosing the right valves and fittings is vital in any plumbing project. Each type has unique functions and features. Understanding these can save you time and resources.

There are several types of valves. Gate valves are great for on/off control. They are not for throttling. Ball valves offer excellent sealing. They work well for quick shut-offs. Check valves prevent backflow. They are essential in many systems. Don't overlook their importance.

**Tip:** Always consider the pressure requirements. Choosing valves that fit your project's needs makes a difference.

Fittings connect pipes securely. There are elbows, tees, and couplings. Each serves a specific purpose. Elbows change pipe direction, while tees create branches. Couplings connect two pipes together. Choosing the right fitting can be tricky. Sometimes, oversights happen.

**Tip:** Measure twice before cutting. This helps avoid mistakes and wasted materials. It's a simple way to improve accuracy. Using the wrong fitting can lead to leaks or burst pipes.

Key Factors to Consider: Material Compatibility and Pressure Ratings

Choosing the right valves and fittings for your project requires careful thought. Material compatibility is crucial. Each material interacts differently with fluids. For example, corrosive substances can damage certain metals. Choosing the wrong material could lead to leaks or failures. Thermoplastics often work well with harsh chemicals. But high temperatures can be an issue.

Pressure ratings are also vital. Each fitting has a maximum pressure limit. Exceeding this can be dangerous. It can cause bursts or other failures. Consider the operating conditions. Think about the worst-case scenarios. Will the system handle fluctuations? Understanding how pressure affects your fittings is essential. It’s easy to overlook these details.

Remember, every project is unique. Strive for the best combination of materials and pressure ratings. Some trial and error may happen. Learn from past mistakes. Aim for reliability over cost. Making the right choices now can save headaches later.

Analyzing Flow Control Needs and Selecting the Right Valve Type

Choosing the right valves and fittings for your project starts with understanding flow control needs. Different applications require specific valve types to ensure optimal performance. Research indicates that improper selection can lead to a 20% increase in operational costs. This emphasizes the importance of careful analysis.

When assessing flow characteristics, consider factors like pressure, temperature, and fluid type. For instance, high-pressure systems often require heavy-duty control valves. A 2021 industry report indicated that ball valves accounted for 30% of the market due to their versatility. However, they might not be ideal for all scenarios.

Remember, not every valve type fits all applications. Sometimes, a butterfly valve could provide better flow rates and less space. Yet, these require critical evaluation to avoid installation errors. Reflect on the specific demands of your project. Balancing functionality with cost can be challenging. Thoughtful choices make a significant impact on efficiency.

Evaluating Industry Standards and Certifications for Quality Assurance

When it comes to selecting valves and fittings, industry standards play a crucial role. Adhering to established certifications can significantly impact the quality of your project. According to a recent industry report, nearly 45% of failures in piping systems arise from non-compliance with these standards. Many manufacturers provide documentation that proves their products meet or exceed required specifications. Without this, the risk of failure increases dramatically.

Moreover, the mismatch in material standards can lead to severe issues. For example, a study indicated that 30% of system failures were due to inappropriate material selection. When selecting products, it’s essential to verify if they adhere to standards such as ASME, API, or ASTM. This helps ensure their longevity and functionality under pressure. Project managers often overlook this, leading to costly rework and safety hazards.

Beyond specifications, industry certifications also signify a commitment to quality. However, many buyers may find the abundance of certifications overwhelming. Not all certifications guarantee the same level of quality assurance. Engaging with professionals who understand these nuances can provide clarity. This vigilance is not just a best practice; it’s a necessity in ensuring project success.

Cost-Benefit Analysis: Budgeting for Valves and Fittings in Your Project

When budgeting for valves and fittings, understanding the cost-benefit analysis is crucial. According to a report by the Valve Manufacturers Association, valves and fittings can account for 20-30% of a project’s total cost. This percentage highlights the importance of selecting the right components to balance quality and budget.

Evaluating different valve materials is essential. For instance, stainless steel might have a higher upfront cost but offers durability. This can reduce long-term maintenance costs. In contrast, plastic fittings may be cheaper, but they might not withstand high-pressure systems. Such choices can lead to unexpected expenses down the line.

Moreover, labor costs associated with installation should not be overlooked. Selecting the right fittings can streamline operations. For example, improper fittings can require additional modifications during installation. This often results in project delays and higher labor costs. Prioritizing quality over initial savings can influence a project’s success. It’s vital to consider both upfront costs and long-term value for a wiser investment.

Cost-Benefit Analysis of Valves and Fittings in Your Project

Related Posts

-

5 Key Factors for Sourcing the Best Flanges and Fittings in Today's Global Market

-

Ultimate Checklist for Choosing the Right Flanges and Fittings for Your Project

-

Exploring Innovative Alternatives to Stainless Fittings: Industry Insights and Trends

-

How to Choose the Right Flanges and Fittings for Your Project

-

Top 10 Essential Fittings and Valves You Need for Your Plumbing Projects

-

Why Are Plug Valves Essential for Industrial Applications?