Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

2025 How to Choose the Right Globe Valves for Your Projects Effectively

In the intricate world of industrial piping systems, the selection of the right components is crucial for ensuring efficiency and reliability. Globe valves, known for their ability to regulate flow effectively, play a critical role in various applications across multiple sectors. According to industry expert John Smith, a leading authority on valve technologies, “Choosing the right globe valves can significantly enhance system performance and reduce maintenance costs.” This highlights the importance of making informed decisions when selecting these vital components for your projects.

As we delve into the nuances of globe valves, it becomes essential to understand the different types, materials, and design considerations that influence performance and suitability for specific applications. A well-chosen globe valve not only aids in flow control but also contributes to the longevity of the piping system. The following guide aims to provide insights and practical advice on how to effectively choose the right globe valves for your projects, ensuring optimal functionality and compliance with industry standards. With the right approach, you can navigate the complexities of valve selection and make decisions that yield lasting benefits for your operations.

Understanding Globe Valves: Types and Applications in Various Industries

Globe valves are essential components in various industries, primarily used for regulating fluid flow. Their unique design, characterized by a globular body shape, allows for significant throttling capability, making them suitable for applications requiring precise control of flow rates. Commonly found in oil and gas, chemical processing, and water treatment sectors, globe valves provide reliable performance and durability under high-pressure conditions.

When selecting globe valves for your project, consider the material construction based on the fluid being handled. Common materials include brass, stainless steel, and cast iron, each offering specific benefits depending on the industry's requirements, such as corrosion resistance or temperature tolerance. Additionally, pay attention to the valve size and pressure ratings to ensure optimal performance.

**Tips**: Always assess the application’s operating conditions and choose a valve that meets those specific demands. This includes evaluating temperature ranges and compatibility with the fluid type. Furthermore, consulting with industry professionals can offer valuable insights into selecting the best globe valve for your needs. Always keep maintenance considerations in mind; valves that are easier to inspect and maintain can save time and costs over the lifecycle of the project.

Key Factors to Consider When Selecting Globe Valves for Your Project

When selecting globe valves for your projects, several key factors must be considered to ensure optimal performance and reliability. One of the primary aspects is the valve's material. According to industry data from the Global Valve Market Report, stainless steel and cast iron are among the most commonly used materials due to their durability and resistance to various fluids. Additionally, the specific application—whether for high-pressure steam systems or corrosive chemical processes—will dictate the appropriate material choice.

Another crucial factor is the sizing of the globe valve. Proper sizing directly influences the valve’s flow characteristics and overall system efficiency. The valve must be selected based on the pressure drop, maximum flow rate, and the characteristics of the medium being controlled. Research suggests that an incorrectly sized valve can lead to increased energy consumption and maintenance costs, emphasizing the importance of accurate calculations and specifications during the selection process.

Tips: Always refer to industry standards and guidelines when choosing a valve. The American National Standards Institute (ANSI) provides detailed resources that can help in making informed decisions. Additionally, consulting with experienced engineers can provide insight into best practices that align with your specific project needs. Don't overlook the importance of testing the valves in your system to verify performance before full-scale implementation.

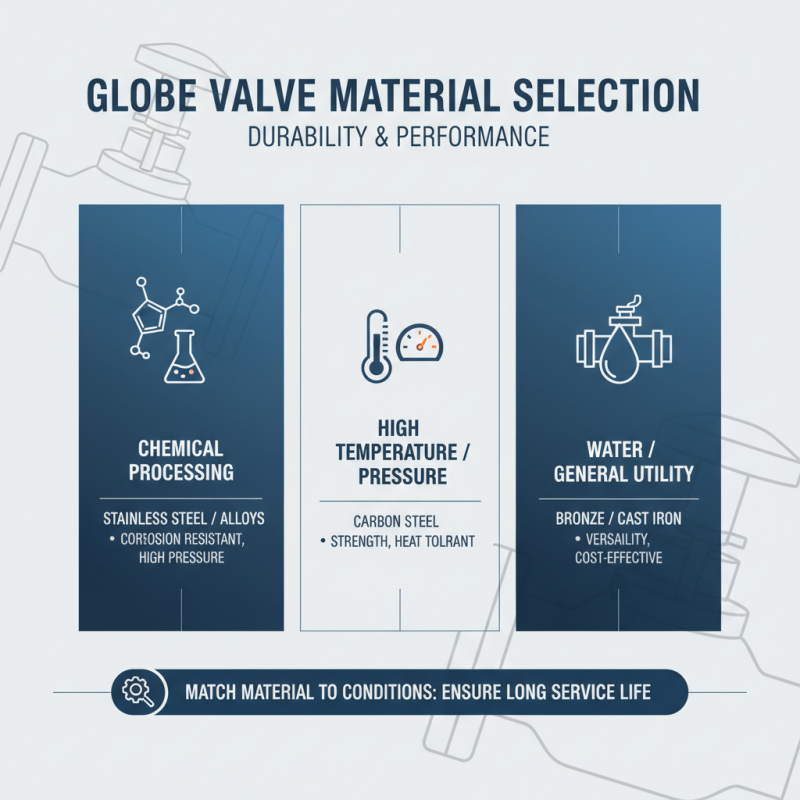

Material Compatibility: Choosing the Right Globe Valve Material for Durability

When selecting globe valves for your projects, material compatibility is paramount to ensuring durability and performance. Different applications require specific materials that can withstand environmental factors, pressures, and temperatures. For instance, in chemical processing plants, valves made from stainless steel or alloys might be essential due to their resistance to corrosion and strength under high pressure. Understanding the chemicals and conditions the valve will be exposed to is crucial; this knowledge guides engineers in choosing the right material that can provide a long service life and minimize maintenance costs.

Another key factor to consider is the temperature range of the application. Materials such as brass or PVC may be suitable for lower temperature applications, while high-temperature systems may necessitate the use of special materials like carbon steel or titanium. Additionally, the physical properties of the fluid, such as viscosity and potential for crystallization or sludging, can affect the choice of valve material. By paying close attention to these aspects, you can select globe valve materials that not only meet operational requirements but also enhance the overall reliability and longevity of your system.

Pressure and Temperature Ratings: Ensuring Safety and Efficiency in Selection

When selecting globe valves for your projects, understanding the pressure and temperature ratings is crucial to ensure both safety and efficiency. The pressure rating indicates the maximum pressure the valve can handle without risk of failure, while the temperature rating defines the limits of thermal stability under operational conditions. These parameters directly affect the valve’s performance and longevity, making them essential considerations in your selection process.

Tips: Always consult the manufacturer’s specifications to determine the appropriate pressure and temperature ratings for your specific application. It’s advisable to factor in safety margins to accommodate potential fluctuations in operating conditions, thereby avoiding premature valve degradation.

It’s also important to match the valve's materials with the intended service conditions. For instance, if your project involves corrosive fluids or extreme temperatures, ensure that the selected globe valve can withstand those specific conditions. Include a thorough review of the operating environment and the physical properties of the media when making your choice, as this will enhance operational efficiency and minimize downtime.

Cost-Benefit Analysis: Evaluating Price vs. Performance in Globe Valve Choices

When selecting globe valves for a project, a thorough cost-benefit analysis is crucial. The initial price of a globe valve often plays a significant role in decision-making; however, it is essential to weigh this against long-term performance and reliability. In some cases, opting for a valve with a higher upfront cost may lead to greater savings over time if it results in lower maintenance requirements, longer service life, and improved operational efficiency. Evaluating these factors can help ensure that the valve selected will meet not just immediate budget considerations, but also the demands of long-term performance.

Furthermore, assessing the performance characteristics of globe valves, such as flow capacity, pressure drop, and resistance to wear and corrosion, is vital in making an informed choice. While less expensive options may seem attractive, they can often compromise efficiency or lead to frequent replacements, ultimately increasing total ownership costs. By conducting a systematic evaluation of both price and performance, project managers can make better selections that optimize their budgets while still ensuring the reliability and effectiveness of their systems. This balanced approach will ultimately contribute to the success of any project where globe valves are utilized.

2025 How to Choose the Right Globe Valves for Your Projects Effectively - Cost-Benefit Analysis

| Valve Type | Price ($) | Pressure Rating (psi) | Flow Coefficient (Cv) | Material | Applicable Temperature (°F) | Warranty (Years) |

|---|---|---|---|---|---|---|

| Standard Globe Valve | 150 | 300 | 80 | Cast Iron | -20 to 150 | 2 |

| Stainless Steel Globe Valve | 250 | 600 | 120 | Stainless Steel | -50 to 400 | 5 |

| Bronze Globe Valve | 200 | 450 | 100 | Bronze | 0 to 250 | 3 |

| PVC Globe Valve | 80 | 150 | 50 | PVC | -20 to 140 | 1 |

Related Posts

-

2025 Top 5 Globe Valves You Need to Consider for Your Projects

-

5 Key Benefits of Choosing the Right Fittings and Valves for Your Projects

-

How to Choose the Right Valves Fittings for Your Plumbing Needs

-

Top 10 Essential Fittings and Valves You Need for Your Plumbing Projects

-

How to Choose the Right Floating Ball for Your Industrial Applications

-

10 Essential Tips for Choosing the Right Needle Valves for Your Projects