Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

What is a Gate Valve and How Does It Work?

Gate valves are essential components in many industrial applications, controlling fluid flow and pressure. According to the Global Gate Valve Market Report, the industry is projected to grow at a CAGR of 4.5% from 2021 to 2026. This growth is driven by increased demand in sectors such as oil and gas, water treatment, and power generation.

Expert in valve technology, Dr. Emily Carter, notes, “Gate valves offer an ideal solution for applications where minimal pressure drop is required.” This highlights the importance of gate valves in maintaining efficiency in fluid systems. However, it is crucial to consider the limitations of gate valves. They are not designed for throttling and can lead to turbulence if misused.

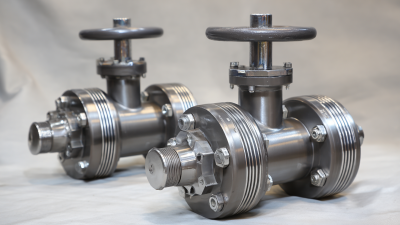

The versatility of gate valves is notable. They can handle high pressures and are often made from durable materials like stainless steel. Still, operators should not overlook maintenance. Neglect can lead to performance issues. Overall, understanding how gate valves function is vital for effective system design and operation.

Understanding the Basics of Gate Valves and Their Applications

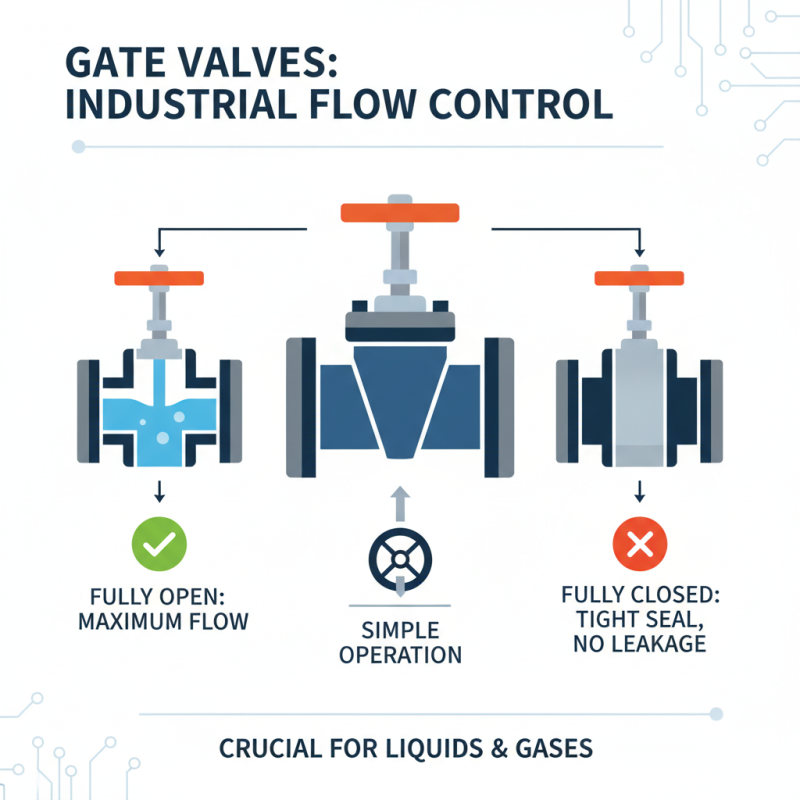

Gate valves are crucial components in various industrial applications. They are designed to control the flow of liquids and gases. The operation is simple yet effective. When the valve is fully open, it allows for maximum flow. When closed, it creates a tight seal, preventing any leakage.

These valves are often used in pipelines for water, sewage, and oil. Their straightforward design makes them easy to operate. However, they are not ideal for regulating flow. If you need precise control, consider other types of valves. Gate valves work best when they are either fully open or fully closed. This can lead to potential inefficiencies in some systems.

In many cases, maintenance is important. Regular inspections can prevent issues. Sometimes, gate valves can suffer from wear and tear. This might lead to difficulties in operation. A stuck gate valve can disrupt a whole process. It’s essential to understand these challenges to use gate valves effectively.

The Mechanism of Gate Valves: How They Operate

Gate valves are crucial in controlling fluid flow. They operate using a simple mechanism. When the valve is opened, a flat gate, or disc, is lifted away from the flow path. This allows liquid or gas to pass through unobstructed. When closed, the gate seals tightly against the seat, preventing leakage.

The operation of gate valves can be quite straightforward. A rotating wheel or lever is usually the operator. As you turn it, the gate moves up or down. This action can be slow, requiring patience. Sometimes, it does not fully open or close. This can lead to inefficiencies. Understanding this mechanism is essential for maintenance and troubleshooting.

Gate valves work best when fully open or fully closed. They are not designed for throttling flow. Operating them partially can cause damage over time. Some users may forget this critical point. Regular checks can prevent issues and extend the valve's lifespan. Familiarity with their operation leads to safer system management.

Gate Valve Performance Characteristics

This chart illustrates key performance characteristics of a gate valve, including pressure drop, flow rate, operation speed, and leakage rate. Gate valves are designed to provide minimal resistance to flow when fully open and are commonly used in applications requiring on/off control.

Types of Gate Valves: A Comprehensive Overview

Gate valves are essential components in various piping systems. They serve a critical role in controlling fluid flow. Understanding the types of gate valves is vital for choosing the right one.

There are several types of gate valves to consider.

Wedge gate valves are the most common type. They feature a wedge-shaped disk. This design provides a tight seal when closed. Another type is the parallel slide gate valve. These valves have two parallel disks. They allow for smooth operation in high-pressure applications.

Lastly, the rising stem gate valve features a stem that moves upward when the valve opens. This design makes it easy to see the valve’s position.

Each type has its advantages and disadvantages. Wedge valves can be prone to corrosion. Parallel slide valves may require precise alignment. The rising stem valve might take up more vertical space. Choosing the right valve involves careful consideration. It’s not just about functionality; understanding the specific needs of your system is crucial.

Advantages and Disadvantages of Using Gate Valves

Gate valves are commonly used in industrial applications due to their design. They provide a reliable method to start or stop fluid flow. However, there are both advantages and disadvantages to consider.

On the positive side, gate valves offer minimal pressure loss when fully opened. This can be crucial in processes where flow rate matters. According to a report by the American Society of Mechanical Engineers, gate valves can handle high pressure and temperature, making them suitable for various environments. They also seal well when closed, preventing leaks. But it's essential to note that they are not suitable for throttling. If used in that manner, they can cause erosion of the discs and seats.

Despite their strengths, gate valves have some drawbacks. They require significant space for installation. This can be problematic in tighter spaces. Maintenance can also be more challenging than other valve types. Some users report difficulties in replacing them. It's vital to evaluate your system's layout and maintenance capabilities before deciding.

Tips: Regular inspections can help identify early signs of wear. This could save time and money. Always consider operational requirements. Some systems may benefit from a different valve type.

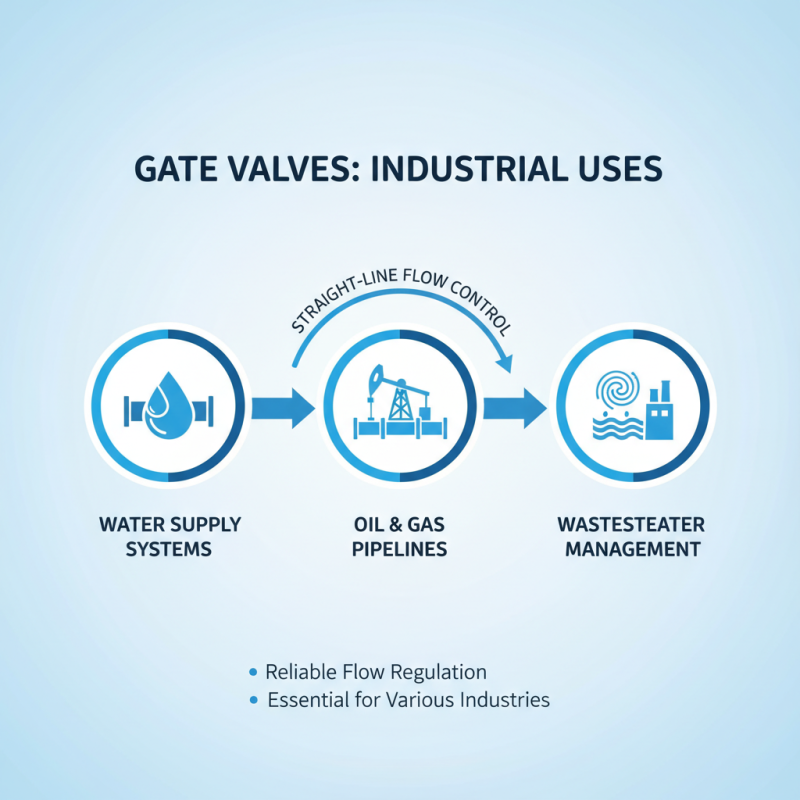

Common Applications and Industries Utilizing Gate Valves

Gate valves find their purpose across various industries. They are crucial in water supply systems, oil and gas pipelines, and wastewater management. Whether it’s controlling the flow of water or oil, gate valves are reliable. They are often used in applications where a straight-line flow is essential.

In the manufacturing sector, gate valves play an important role too. They facilitate the operation of chemical processes. Many factories rely on gate valves for their efficiency. However, improper installation can lead to leaks and failures. Maintenance is key in these situations.

**Tips:** Regular inspections help in preventing problems. Always check for wear and tear in older valves. Upgrade where necessary to maintain system integrity.

Gate valves are also utilized in firefighting systems. They can quickly shut off water supply in emergencies. Still, training is needed for personnel to operate them effectively. Mistakes can be costly in critical moments.

**Tips:** Ensure all staff are properly trained. Hold regular drills to practice valve operation. Being prepared is vital for safety.

Related Posts

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

What Are Gate Valves and How Do They Work?

-

Top Stainless Steel Valves Types and Their Applications?

-

Ultimate Checklist for Choosing the Right Flanges and Fittings for Your Project