Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

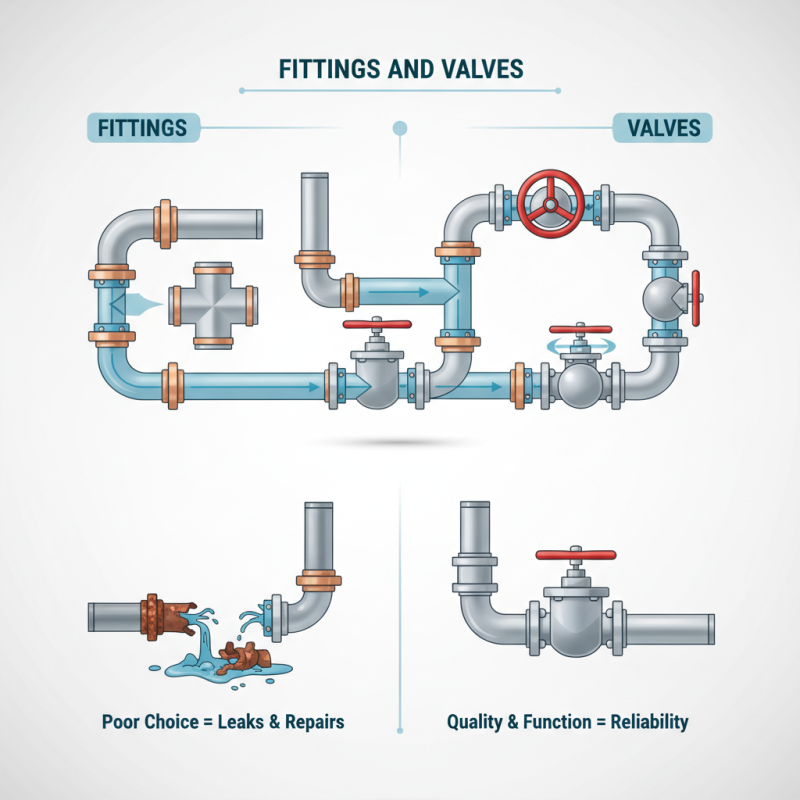

What are Fittings and Valves and How are They Used?

Fittings and valves play a crucial role in various industries, from plumbing to oil and gas. These components control the flow of fluids and gases. They connect pipes and regulate pressure. Understanding their functions is essential for anyone working with fluid systems.

Fittings are the connectors, enabling easy assembly and disassembly. They come in various shapes, such as elbows and tees. Valves, on the other hand, control flow by opening and closing. They can be manual or automatic and are vital for system safety. Without proper fittings and valves, leaks and pressure problems may occur.

Often, people overlook the importance of quality in fittings and valves. A poor choice can lead to failures and costly repairs. It’s necessary to consider not just the price but the functionality. The selection process should involve careful thought and analysis of specific needs. Balancing quality and cost is challenging but crucial for long-term reliability.

Definition of Fittings and Valves in Plumbing Systems

Fittings and valves play a crucial role in plumbing systems. They connect various pipes, directing the flow of fluids. Fittings come in different shapes, such as elbows, tees, and couplings. Each shape serves a specific purpose, allowing for flexibility in installation. Valves control the flow and pressure of water or gas. They can be turned on or off, making them essential for managing plumbing systems.

In plumbing, fittings and valves must work together efficiently. For instance, a leaky fitting might cause water damage over time. Similarly, a malfunctioning valve can disrupt the entire system. It’s essential to regularly inspect these components. Many homeowners overlook this aspect of maintenance. Frequent checks can prevent costly repairs down the line.

Choosing the right fittings and valves is vital. The materials and sizes must match the plumbing layout. Often, mistakes happen in this area. Using the wrong component can lead to issues like leaks or low pressure. Understanding these parts helps ensure a well-functioning plumbing system.

Types of Fittings and Valves and Their Specific Uses

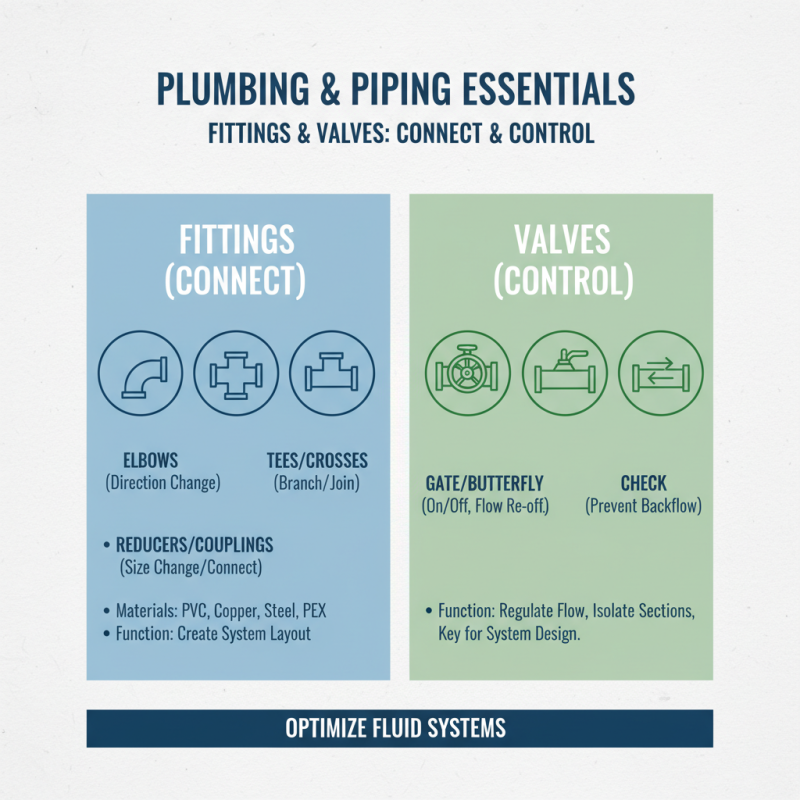

Fittings and valves are essential components in plumbing and piping systems. They connect various segments of pipes and regulate fluid flow. Understanding their types and uses is crucial for effective system design.

There are several types of fittings, including elbows, tees, and couplings. Elbows change the direction of a pipe, allowing for flexible installations. Tees branch off a pipe, enabling multiple outlets. Couplings connect two pipe ends, ensuring a secure fit. Each fitting plays a critical role in maintaining the integrity of a fluid system.

Valves control the flow of liquids and gases. Common types include gate valves, ball valves, and globe valves. Gate valves are excellent for on/off control. Ball valves provide quick shut-off with minimal pressure drop. Globe valves are better for regulating flow, albeit with more resistance. Choosing the right valve is essential to improve system efficiency.

Tips: Always ensure fittings are compatible with your piping material. Regularly inspect fittings and valves for leaks. A minor leak can lead to significant issues later. Furthermore, consider the specific application when choosing between valve types. Each has its characteristics that can affect performance. Making the right choice requires attention to detail.

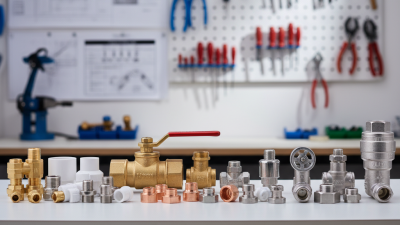

Material Composition of Fittings and Valves

Fittings and valves play crucial roles in various piping systems. Understanding their material composition helps in selecting the right components for a project. Common materials include metal, plastic, and rubber. Each material has its advantages and limitations.

Metal fittings and valves, often made from brass or stainless steel, are durable and suitable for high-pressure applications. However, they can corrode over time. Plastic options are lightweight and resistant to corrosion, perfect for chemical applications. Yet, they may not withstand high temperatures. Rubber gaskets help with sealing but wear out quickly.

Tips: Consider the specific requirements of your project. Temperature, pressure, and the type of fluid matter. Always check compatibility with selected materials. Using mismatched materials can lead to failures. Don’t forget to account for environmental factors. They can influence material performance. Keeping a detailed inventory of materials can avoid future issues.

Installation and Maintenance Procedures for Fittings and Valves

Installing and maintaining fittings and valves is crucial in various industries. According to a recent industry report, improper installation can lead to a 30% increase in leaks and failures. These fixtures are essential for controlling fluid flow and pressure in pipelines. Without proper procedures, the risk of costly downtimes escalates.

When installing fittings and valves, it’s important to follow specific guidelines. Ensure all surfaces are clean and free from debris. Misalignment during installation can cause stress on connections. In some cases, incorrect torque can even result in valve failure. A study showed that nearly 25% of valve issues stem from flawed installation practices. This highlights the need for thorough training and adherence to standards.

Maintenance practices are equally vital. Regular inspections can prevent unexpected breakdowns. A routine check-up can catch wear and tear before it becomes a major problem. Reports indicate that frequent monitoring can reduce operational costs by up to 20%. Neglecting these checks can create a false sense of security, leading to failures that could be easily avoided.

What are Fittings and Valves and How are They Used? - Installation and Maintenance Procedures for Fittings and Valves

| Component Type | Function | Installation Procedure | Maintenance Tips |

|---|---|---|---|

| Pipe Fittings | Connect different sections of piping | Ensure proper alignment; use appropriate seals | Check for leaks; replace wear parts regularly |

| Ball Valves | Regulate fluid flow | Install in line with flow direction; use Teflon tape | Test operation; lubricate stem if necessary |

| Check Valves | Prevent backflow in piping systems | Install with correct orientation to allow unidirectional flow | Inspect for debris; clean if necessary |

| Gate Valves | Fully open or close flow | Use wrench for tight installation; check alignment | Regularly exercise the valve to avoid sticking |

| Elbow Fittings | Change direction of piping | Ensure adequate space for fitting; use solvent cement | Inspect joints; reinforcement may be required for large pipes |

Common Applications of Fittings and Valves in Various Industries

Fittings and valves play crucial roles in many industries. In plumbing, they connect pipes and control water flow. A simple elbow fitting allows for directional changes in piping systems. Valves, like ball valves, can shut off flow entirely or limit it. These tools enable efficient water management and minimize leaks.

In the HVAC industry, fittings and valves help regulate airflow and temperature. Duct fittings are essential for directing air within buildings. They can become a source of inefficiency if not properly sealed. Valves in heating systems allow for better temperature control but require regular maintenance. Failing to do so can lead to uncomfortable environments.

Manufacturing processes also rely on these components. Fittings connect different systems, ensuring smooth operation. In chemical industries, specialized valves prevent hazardous leaks. However, improper installation can result in serious issues. Regular inspections of fittings and valves are necessary to avoid costly downtime and safety risks.

Related Posts

-

How to Choose the Right Valves Fittings for Your Plumbing Needs

-

2025 Top 5 Globe Valves You Need to Consider for Your Projects

-

Top 10 Essential Fittings and Valves You Need for Your Plumbing Projects

-

2025 How to Choose the Right Globe Valves for Your Projects Effectively

-

5 Key Benefits of Choosing the Right Fittings and Valves for Your Projects

-

Top Strategies for Sourcing High Quality Steel Fittings