Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

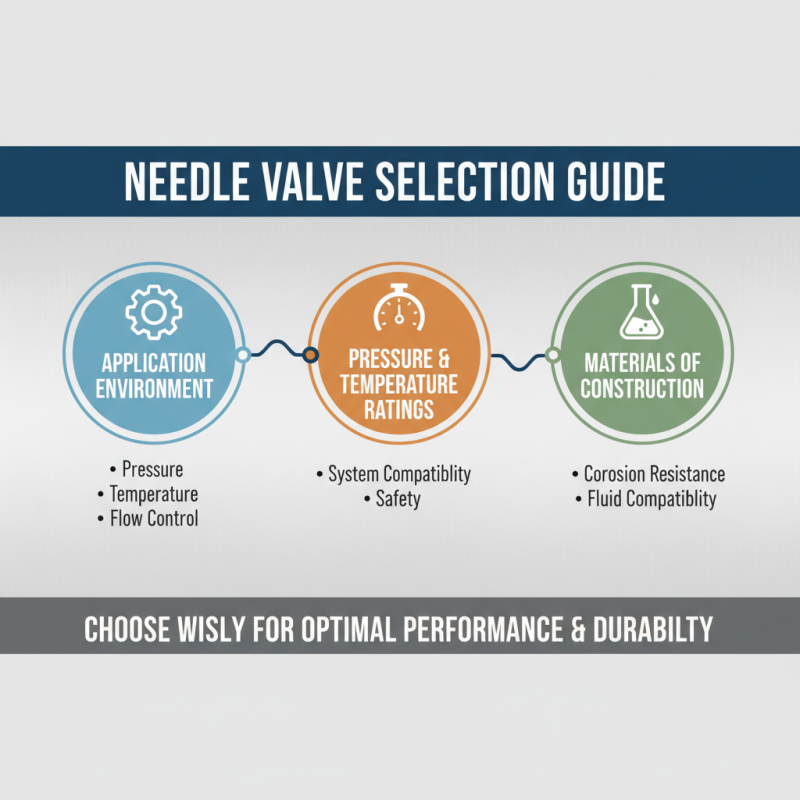

10 Essential Tips for Choosing the Right Needle Valves for Your Projects

Choosing the right needle valves for your projects can significantly impact the efficiency and effectiveness of your systems. As experts in the field stress, the importance of selecting quality needle valves cannot be overstated. Michael Thompson, a renowned expert in fluid dynamics, emphasizes, "The right needle valve can make all the difference in ensuring precise flow control and system reliability." This statement underlines the critical role these components play in various applications, from industrial operations to intricate laboratory experiments.

In this article, we will explore ten essential tips to guide you in your selection process. Understanding the characteristics and specifications of needle valves is vital for achieving optimal performance. The intricacy involved in choosing the appropriate materials, sizes, and types can often be daunting, but these tips are designed to simplify that journey. Whether you are a seasoned professional or a newcomer to working with needle valves, our insights will help you make informed decisions that ultimately enhance the quality and safety of your projects.

Understanding the Basics of Needle Valves and Their Applications

Needle valves are precision instruments designed for the regulation of fluid flow within a system. Characterized by their slender needle-like component, these valves allow for fine adjustments, making them ideal for applications that require precise flow control. They are commonly used in hydraulic systems, gas applications, and various industrial processes where the ability to manage flow rate effectively is crucial. Understanding the operating principles of needle valves is essential for selecting the right type for your project.

The application of needle valves spans across diverse industries, from chemical processing to water treatment facilities. Their ability to withstand high pressures and maintain accurate flow rates makes them indispensable for laboratory setups where precise measurements can significantly impact outcomes. Additionally, needle valves are often employed in systems where a gradual increase or decrease of flow is required, which is vital in preventing sudden pressure surges and ensuring system stability. When choosing needle valves, it’s important to consider factors such as the type of fluid, temperature, and pressure conditions to ensure optimal performance in your specific application.

Key Factors to Consider When Selecting Needle Valves for Your Project

When selecting needle valves for your project, one of the key factors to consider is the application environment. Different applications may require valves that can withstand varying pressures and temperatures. For example, if you are working in a high-pressure system, you must ensure that the needle valve is rated for the appropriate pressure levels. Additionally, the materials of construction are crucial; stainless steel might be ideal for corrosive environments, whereas brass could suffice for less demanding conditions.

Another important consideration is the valve size and flow characteristics. The sizing of the valve should match the system requirements to maintain optimal flow rates and avoid unnecessary pressure drops. Furthermore, understanding the flow coefficient (Cv) of the needle valve can help you select a valve that meets your flow needs efficiently. It's also valuable to assess the configuration of the valve, including the type of connections and whether the design allows for easy maintenance and operation. By thoughtfully considering these factors, you can ensure that the selected needle valves will perform reliably and effectively throughout your project's lifecycle.

Materials and Construction: Choosing Durable Needle Valves

When selecting needle valves for any project, understanding the materials and construction is paramount to ensure durability and performance. Needle valves are commonly constructed from various materials like stainless steel, brass, and plastic, each offering unique benefits. According to industry reports from the Valve Manufacturers Association, stainless steel is noted for its superior corrosion resistance and strength, making it ideal for high-pressure applications and harsh environments. In contrast, brass valves are often chosen for their affordability and good thermal conductivity, making them versatile for various fluid control scenarios.

Furthermore, the construction quality of needle valves plays a critical role in their longevity and reliability. A study published in the Journal of Fluids Engineering indicates that valves with precision-machined components demonstrate a significant reduction in leakage and operational failures. This highlights the importance of investing in well-constructed valves that feature high-quality seals and robust bodies. Factors such as temperature tolerance and chemical compatibility should also be considered in material selection, as these elements can directly impact the valve's lifespan and effectiveness in specific applications. Ultimately, choosing durable needle valves crafted from suitable materials is essential for optimizing performance and ensuring project success.

Material Strength Comparison for Needle Valves

Sizing and Flow Rate: Ensuring Compatibility with Your System

When selecting needle valves for your project, understanding the sizing and flow rate is crucial to ensure compatibility with your system. Needle valves are designed to control flow rates with precision, making it imperative to match the valve size to the specific requirements of your application. If the valve is too small, it may restrict flow, causing pressure buildup and inefficiencies in your system. Conversely, an oversized valve can lead to excessive flow rates, which may affect the overall performance and effectiveness of your operation.

To accurately determine the appropriate size for your needle valve, assess the flow rate needed for your system. Calculate the maximum and minimum flow requirements, and consider the specific characteristics of the fluid being controlled—such as viscosity, temperature, and pressure. This information will guide you in selecting a valve that offers optimal control while maintaining safety and functionality. Additionally, pay attention to the connection size and type to ensure seamless integration with existing piping systems, minimizing any potential leaks or weak points.

10 Essential Tips for Choosing the Right Needle Valves for Your Projects - Sizing and Flow Rate: Ensuring Compatibility with Your System

| Tip Number | Tip Description | Sizing Consideration | Flow Rate (GPM) |

|---|---|---|---|

| 1 | Identify the Purpose of the Needle Valve | Pressure and Temperature Requirements | 0.1 - 5 |

| 2 | Select Appropriate Materials | Corrosion Resistance | 0.5 - 10 |

| 3 | Consider Flow Direction | Inlet and Outlet Design | 1 - 15 |

| 4 | Evaluate the Operating Conditions | Ambient Conditions and Fluid Properties | 2 - 20 |

| 5 | Determine Required Port Size | Matching with Piping System | 3 - 25 |

| 6 | Choose the Right Seal Type | Seal Material Compatibility | 4 - 30 |

| 7 | Account for Required Flow Control | Precision Control vs. General Use | 1 - 50 |

| 8 | Analyze System Compatibility | Complete System Design Review | 5 - 40 |

| 9 | Assess Maintenance Requirements | Ease of Access for Repairs | 3 - 35 |

| 10 | Seek Expert Advice if Necessary | Professional Recommendations | Variable |

Maintenance Tips for Long-lasting Performance of Needle Valves

To ensure the long-lasting performance of needle valves in various applications, regular maintenance is crucial. One of the primary maintenance tips is to perform routine inspections for signs of wear or damage. This involves checking for leaks, ensuring that the valve opens and closes smoothly, and looking for any corrosion on the valve body and connections. If any issues are detected, it is important to address them promptly to prevent further complications.

Another vital aspect of maintaining needle valves is proper lubrication. Maintaining the valve's moving parts with suitable lubricants can significantly extend their lifespan and improve performance. It's also essential to keep the valve clean, removing any debris or build-up that might interfere with its operation. Regular cleaning helps to avoid blockages and ensures consistent flow rates, essential for precise applications. By implementing these maintenance strategies, one can enhance the reliability and longevity of needle valves in any project.

Related Posts

-

How to Choose the Right Needle Valve for Global Industrial Applications

-

Understanding Needle Valves and Their Key Role in Fluid Control Systems

-

How to Choose the Right Flanges and Fittings for Your Project

-

How to Choose the Right Globe Valve for Your Industrial Applications

-

Exploring Weld Bend Innovations and Industry Trends at the 138th China Import and Export Fair 2025

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity