Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

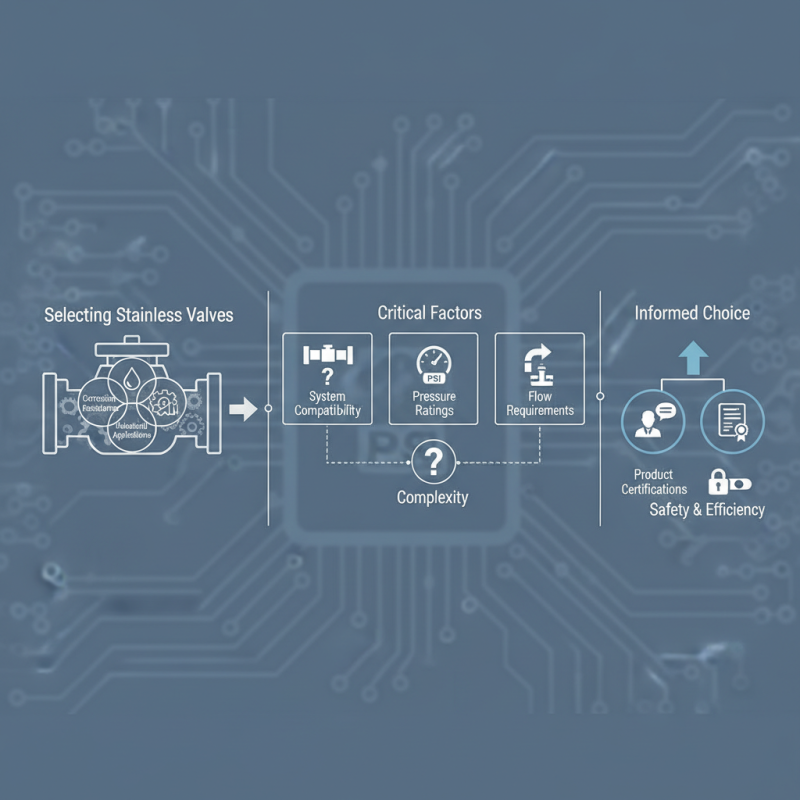

How to Choose the Best Stainless Valves for Your Needs?

Choosing the right stainless valves can significantly impact your project's success. With the global valve market projected to reach $94.89 billion by 2026, the importance of quality is clear. Stainless valves, known for their durability and resistance to corrosion, are essential in various industries, including oil and gas and food processing.

However, selecting stainless valves is often complex. Different materials and specifications affect performance and longevity. According to a recent industry report, nearly 30% of valve failures stem from improper selection. This statistic highlights the need for research and understanding before making a purchase. Compatibility with the system, pressure ratings, and flow requirements are critical factors.

It's easy to overlook these details. Decisions based on cost alone may result in higher expenses later. A well-informed choice can save time and resources. Stainless valves are not just components; they ensure safety and efficiency. Engaging with industry experts and reviewing product certifications can further guide your decision.

Understanding Stainless Steel Valves and Their Applications

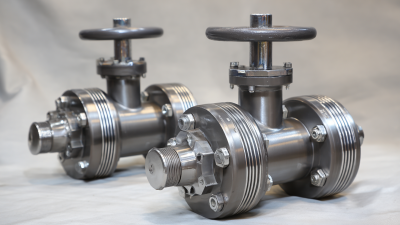

Stainless steel valves are crucial in various industries. They control the flow of liquids and gases. These valves come in different types, including ball, gate, and globe valves. Each type serves a unique purpose in specific applications. Understanding their uses is vital when selecting the right one.

In chemical processing, stainless steel valves resist corrosion. This is essential for handling aggressive substances. In water treatment, these valves offer durability and reliability. They withstand harsh conditions, ensuring long-term performance. However, not all stainless steel grades are equal. Choosing the wrong grade may lead to premature failure.

Proper maintenance of stainless steel valves is often overlooked. Regular checks can prevent operational issues. Minor leaks can escalate into significant problems. Remember, the right choice enhances system efficiency. Yet, the decision process can be challenging. Balancing cost, durability, and application may require careful analysis.

How to Choose the Best Stainless Valves for Your Needs?

| Valve Type | Material Grade | Size (inches) | Pressure Rating (psi) | Temperature Rating (°F) | Application |

|---|---|---|---|---|---|

| Ball Valve | 304 Stainless Steel | 1/2" | 150 | 200 | Water, Oil |

| Gate Valve | 316 Stainless Steel | 2" | 300 | 400 | Steam, Gas |

| Check Valve | 304 Stainless Steel | 1" | 150 | 250 | Wastewater |

| Globe Valve | 316L Stainless Steel | 3/4" | 150 | 300 | Cooling Systems |

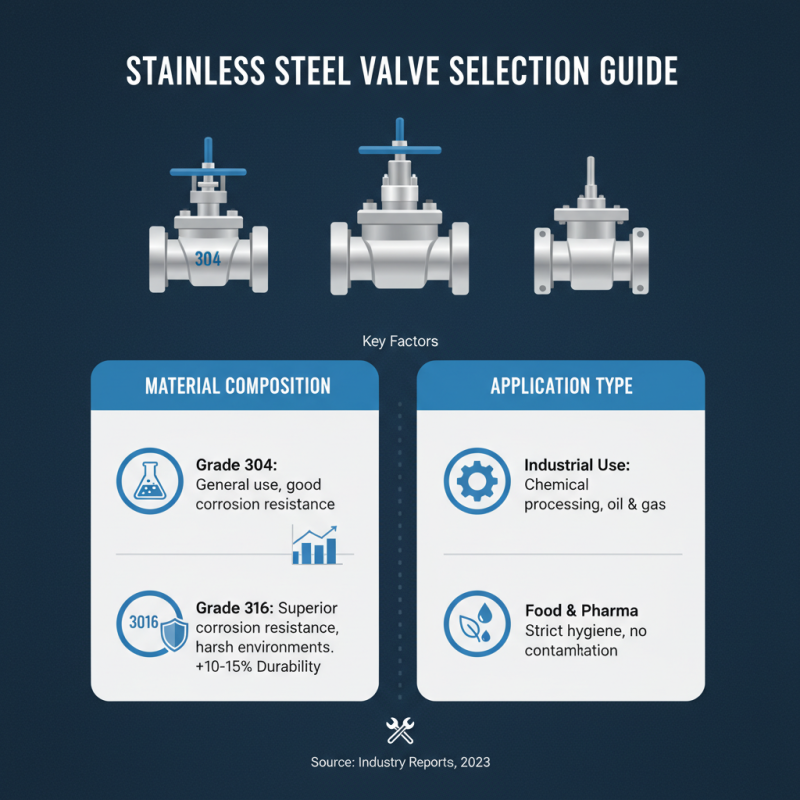

Factors to Consider When Choosing Stainless Steel Valves

When selecting stainless steel valves, several critical factors come into play. Material composition is paramount. Grades like 304 and 316 stainless steel have varying corrosion resistance. Reports indicate that 316 offers better protection in harsh environments, with a 10-15% increase in durability. Consider the type of application as well. Different industries require specific specifications. For instance, food processing demands strict hygiene standards.

Size is another essential factor. A valve that is too small may lead to inadequate flow, while an oversized valve can create unnecessary pressure drops. The industry average shows that up to 25% of inefficiencies stem from improper valve sizing. Additionally, pressure ratings must match your system. Miscalculating pressure tolerances can lead to catastrophic failures.

Don’t overlook the importance of maintenance. Some valves require more frequent checks than others. A study suggests that up to 30% of system failures could be traced back to overlooked maintenance issues. It's vital to understand the longevity of the valve in your specific environment. Reflections on performance can lead to valuable insights that aid in future selections.

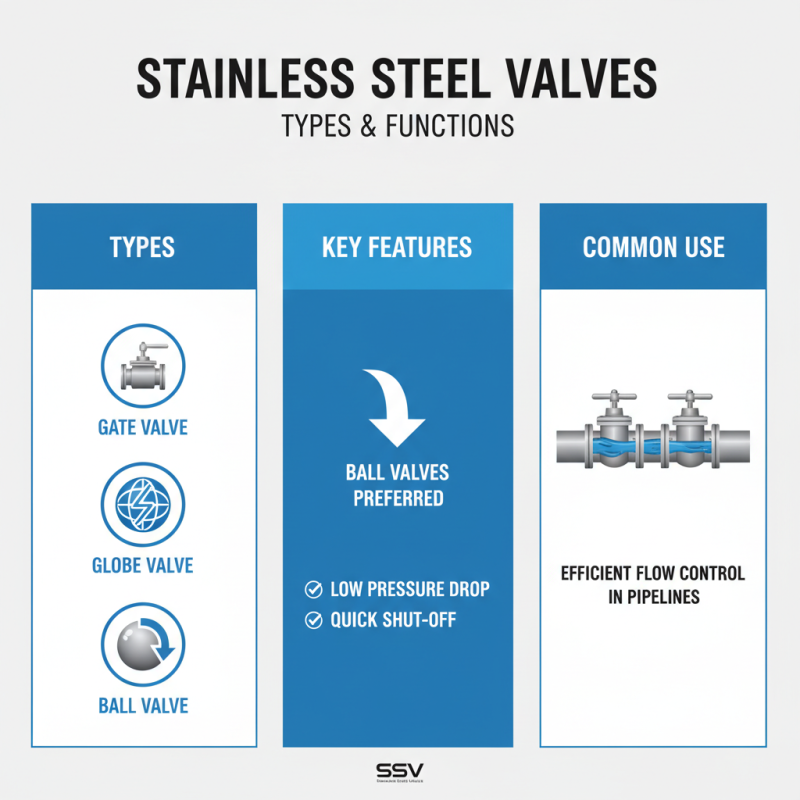

Types of Stainless Steel Valves and Their Functions

When choosing the right stainless steel valves, understanding their types and functions is crucial. Stainless steel valves come in various forms, such as gate, globe, and ball valves. According to industry reports, ball valves are often favored for their low-pressure drop and quick shut-off capabilities. They're widely used in pipelines where efficient flow control is necessary.

Gate valves are another common type. They excel in fully on or off applications. However, they may not be suitable for throttling applications. Studies indicate their performance can decline over time, especially in corrosive environments. Globe valves, on the other hand, are ideal for regulating flow, making them essential in many applications. Their ability to provide precise control is well documented.

Yet, details can be overlooked. For example, some users may not consider the valve's pressure rating or temperature limits. Not all stainless steel grades are equal, and choosing the wrong grade can lead to premature failure. The decision should also factor in the environment. Is it outdoors or indoors? Is there a risk of corrosion? It's vital to reflect on these elements to avoid costly mistakes in valve selection.

Evaluating Material Grades for Optimal Performance

When selecting stainless valves, one crucial aspect is evaluating the material grades. Stainless steel is categorized into various grades, each offering unique benefits. For example, 304 stainless steel is commonly used due to its good corrosion resistance and formability. However, it may not withstand high temperatures as well as 316 stainless steel, which contains molybdenum for better performance in corrosive environments. The difference in alloy composition significantly impacts valve longevity and reliability.

Tip: Always consider the specific environment where the valve will be used. If your application involves aggressive chemicals or extreme temperatures, a higher grade like 317 may be necessary. On the other hand, for standard conditions, 304 might suffice.

Understanding the nuances between grades is essential. Many users may overlook this, leading to premature valve failure. Industry data suggests that valves made from suitable grades have a failure rate significantly lower than those made from lower-quality materials. It’s vital to weigh your specific needs against the material grade’s capabilities. Don’t forget to check certifications and compliance with industry standards. This can prevent costly issues down the line.

Tip: Consult with experts before making a decision. They can help identify the best material grade based on actual use cases. Remember, investing time now can save money later.

Maintenance Tips for Prolonging the Life of Stainless Valves

Maintaining stainless valves is crucial for their durability and efficiency. Regular inspections can identify wear and tear before issues escalate. Checking for leaks or corrosion can save time and money in the long run. Even small signs may indicate larger problems.

Cleaning the valves is key to prolonging their life. Use a soft cloth and a non-abrasive cleaner. Harsh chemicals can damage stainless steel. Rinsing thoroughly after cleaning helps remove residues. Another simple yet effective tip is lubricating moving parts. Proper lubrication prevents sticking and reduces wear.

It’s easy to overlook small details, like the valve seating. Damaged seats can lead to leaks. Addressing these issues early can improve performance. Additionally, storing valves in dry, cool conditions is important. Moisture can lead to rust, even on stainless steel. Ignoring these factors might result in costly replacements later.

Related Posts

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top Stainless Steel Valves Types and Their Applications?

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

How to Choose the Right Stainless Valves for Your Industrial Applications

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications