Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

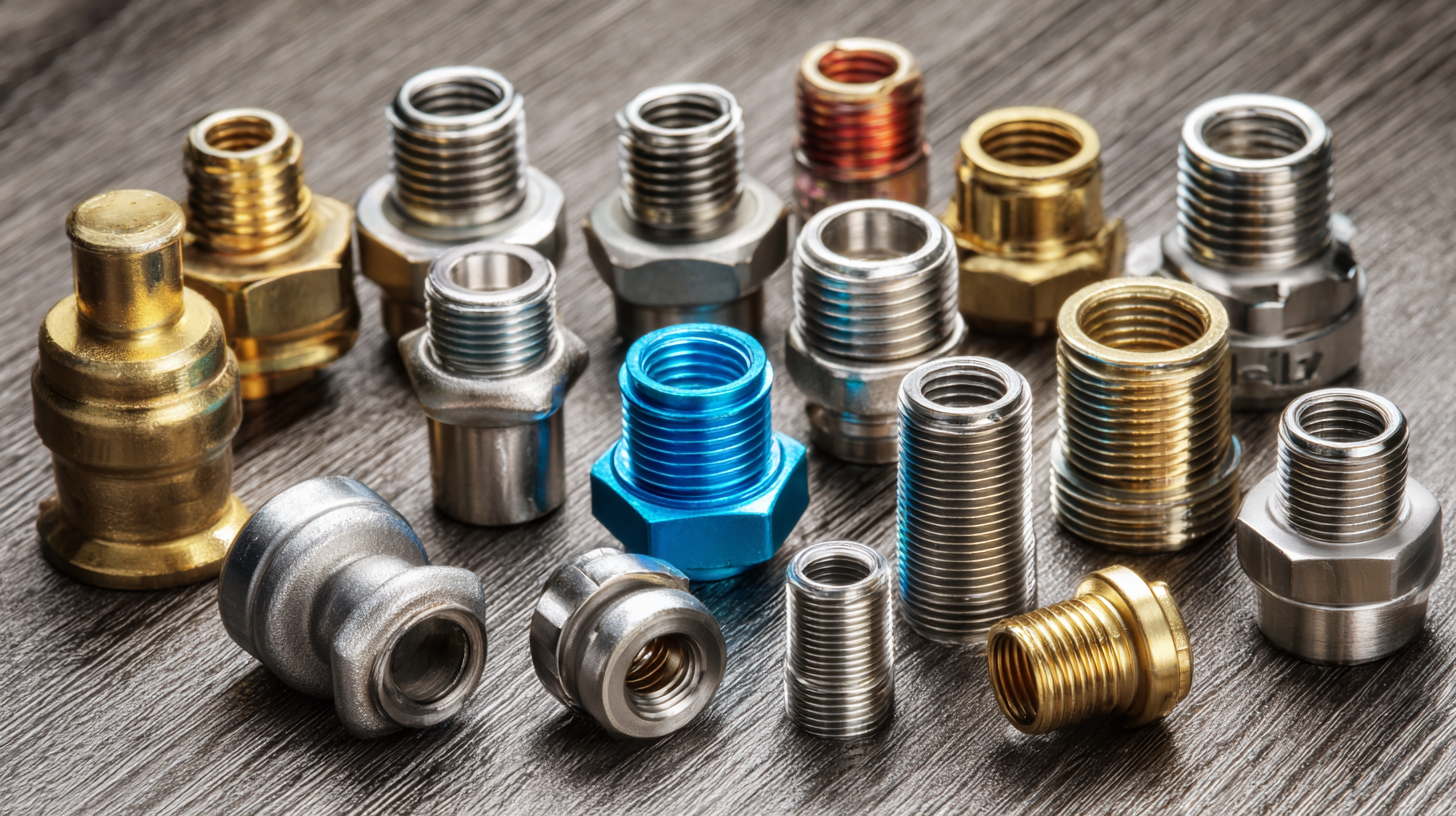

How to Choose the Right Valves Fittings for Your Plumbing Needs

Selecting the appropriate valves fittings for your plumbing needs is critical to ensuring a reliable and efficient water distribution system. According to a report by IBISWorld, the plumbing industry has experienced steady growth, with an estimated market size of $119 billion as of 2022, highlighting the increasing demand for high-quality plumbing components.

Valves fittings play a vital role in regulating flow, pressure, and overall functionality within various plumbing applications. A recent industry analysis indicates that up to 30% of plumbing failures can be traced back to improper fittings selection or installation.

Therefore, understanding the types of valves fittings available and their specific applications is essential for professionals and DIY enthusiasts alike, ensuring not only compliance with safety standards but also enhanced system performance and longevity. With numerous options on the market, making informed decisions regarding valves fittings is paramount to achieving optimal plumbing solutions.

Selecting the appropriate valves fittings for your plumbing needs is critical to ensuring a reliable and efficient water distribution system. According to a report by IBISWorld, the plumbing industry has experienced steady growth, with an estimated market size of $119 billion as of 2022, highlighting the increasing demand for high-quality plumbing components.

Valves fittings play a vital role in regulating flow, pressure, and overall functionality within various plumbing applications. A recent industry analysis indicates that up to 30% of plumbing failures can be traced back to improper fittings selection or installation.

Therefore, understanding the types of valves fittings available and their specific applications is essential for professionals and DIY enthusiasts alike, ensuring not only compliance with safety standards but also enhanced system performance and longevity. With numerous options on the market, making informed decisions regarding valves fittings is paramount to achieving optimal plumbing solutions.

Understanding Different Types of Valves and Fittings for Plumbing

When it comes to plumbing, selecting the appropriate valves and fittings is essential for maintaining an efficient and leak-free system. Various types of valves serve distinct functions; for example, gate valves are excellent for on/off control, while globe valves are better suited for throttling applications. Understanding the difference is crucial for making informed decisions about your plumbing needs.

Tips: Always consider the pressure ratings and material compatibility of the valves and fittings you choose. For high-temperature applications, look for stainless steel or brass options that can withstand the heat without degrading.

Fittings also come in several varieties, including elbows, tees, and couplings, which are integral for connecting pipes and directing flow. Each fitting type has specific functions, so it’s important to understand which one suits your piping layout.

Tips: When installing fittings, ensure that they are properly sized and fit well with your existing pipes to prevent leaks. Using the right solvent or sealant is also vital for ensuring a secure connection.

How to Choose the Right Valves Fittings for Your Plumbing Needs

| Type of Valve | Function | Material | Common Applications |

|---|---|---|---|

| Ball Valve | On/off control | Brass, PVC | Water supply, gas lines |

| Gate Valve | Stop/start flow | Stainless steel, bronze | Water systems, oil pipelines |

| Check Valve | Prevent backflow | PVC, brass | Drainage systems, sewage |

| Pressure Relief Valve | Prevent excessive pressure | Metal | Boiler systems, compressors |

| Ball Valve | On/off control | Brass, PVC | Water supply, gas lines |

| Butterfly Valve | Regulate flow | PVC, metal | HVAC systems, water treatment |

Key Factors to Consider When Selecting Plumbing Valves

When selecting plumbing valves, there are several key factors to consider to ensure proper functionality and longevity. First, it's essential to understand the type of fluid being transported—whether it is water, gas, or another substance—as this will influence the material and design of the valve needed. For instance, different metals and plastics offer varying degrees of resistance to corrosion and pressure, making the right material choice crucial for preventing leaks and ensuring safety.

Tips: Always check the compatibility of the valve material with the fluid it will control. For high-pressure systems, opt for valves specifically rated for those conditions to prevent failures.

Another vital consideration is the valve's size and connection type. Choosing the right diameter is important to maintain efficient flow rates, while the connection type—threaded, soldered, or flanged—must match your existing plumbing system.

Tips: Measure existing pipes carefully and consult compatibility charts to avoid costly mistakes. If you're unsure about the connection style, bringing a sample to a plumbing supply store can help you find the perfect fit.

5 Common Plumbing Issues Addressed by the Right Valves

When it comes to plumbing systems, the choice of valves and fittings is crucial in addressing common plumbing issues. For instance, leaks are one of the most frequent problems homeowners face, often leading to significant water waste. According to the U.S. Environmental Protection Agency (EPA), leaks can waste more than 1 trillion gallons of water annually nationwide. Using quality shut-off valves can help minimize water wastage and quickly address leaks before they escalate.

Another significant issue is water pressure regulation. The American Society of Plumbing Engineers (ASPE) notes that improper pressure can lead to pipe damage and increased water bills. Installing pressure-reducing valves can effectively manage the pressure, ensuring a steady flow without unnecessary strain on the plumbing system. Furthermore, backflow prevention is critical to maintaining safe drinking water. The Centers for Disease Control and Prevention (CDC) emphasize that improper valve selection can lead to contamination, underscoring the importance of backwater valves in protecting potable water sources. Selecting the right valves and fittings plays a vital role in enhancing the longevity and efficiency of your plumbing system.

Essential Tips for Maintaining Your Valves and Fittings

Maintaining valves and fittings is crucial for ensuring the longevity and efficiency of your plumbing system. Regular inspections should be conducted to identify any signs of wear and tear, such as leaks or corrosion. By addressing these issues early, you can prevent more significant problems down the line. It's also advisable to check the tightness of the fittings, as loose connections can lead to water loss and damage.

Routine cleaning is another essential aspect of maintenance. Deposits can accumulate in valves, hindering their performance. Flushing the system periodically helps in removing these deposits and keeps the water flow unobstructed. Additionally, lubricating moving parts of the valves can enhance their operation, ensuring they open and close smoothly.

Keeping a maintenance schedule tailored to your plumbing system's specific requirements is key to achieving optimal performance and avoiding costly repairs in the future.

How to Ensure Compatibility Between Valves and Existing Plumbing Systems

When selecting valves and fittings for your plumbing system, ensuring compatibility with existing components is crucial. Start by examining the type of pipes you currently have—common materials include PVC, copper, and PEX. Each material requires specific fittings that can seal properly and handle the pressure levels in your system. For instance, using a PVC valve with a copper pipe may lead to leaks or damage, as the materials expand and contract differently under pressure.

Additionally, consider the size of the existing pipes when choosing fittings. Valves and fittings come in various sizes, and using the wrong dimensions can disrupt flow and create bottlenecks. Always check the specifications of your pipes and match them with corresponding fittings and valves. It is also wise to consult the plumbing code in your area, as it may stipulate compatibility requirements and best practices for different materials to ensure longevity and safety in your plumbing system. By taking these factors into account, you can make an informed decision that enhances your plumbing’s efficiency.

Related Posts

-

5 Key Benefits of Choosing the Right Fittings and Valves for Your Projects

-

Top Strategies for Sourcing High Quality Steel Fittings

-

How to Choose the Right Flanges and Fittings for Your Project

-

10 Essential Tips for Choosing the Right Flanges and Fittings

-

5 Key Factors for Sourcing the Best Flanges and Fittings in Today's Global Market

-

How to Choose the Right Stainless Valves for Your Industrial Applications