Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

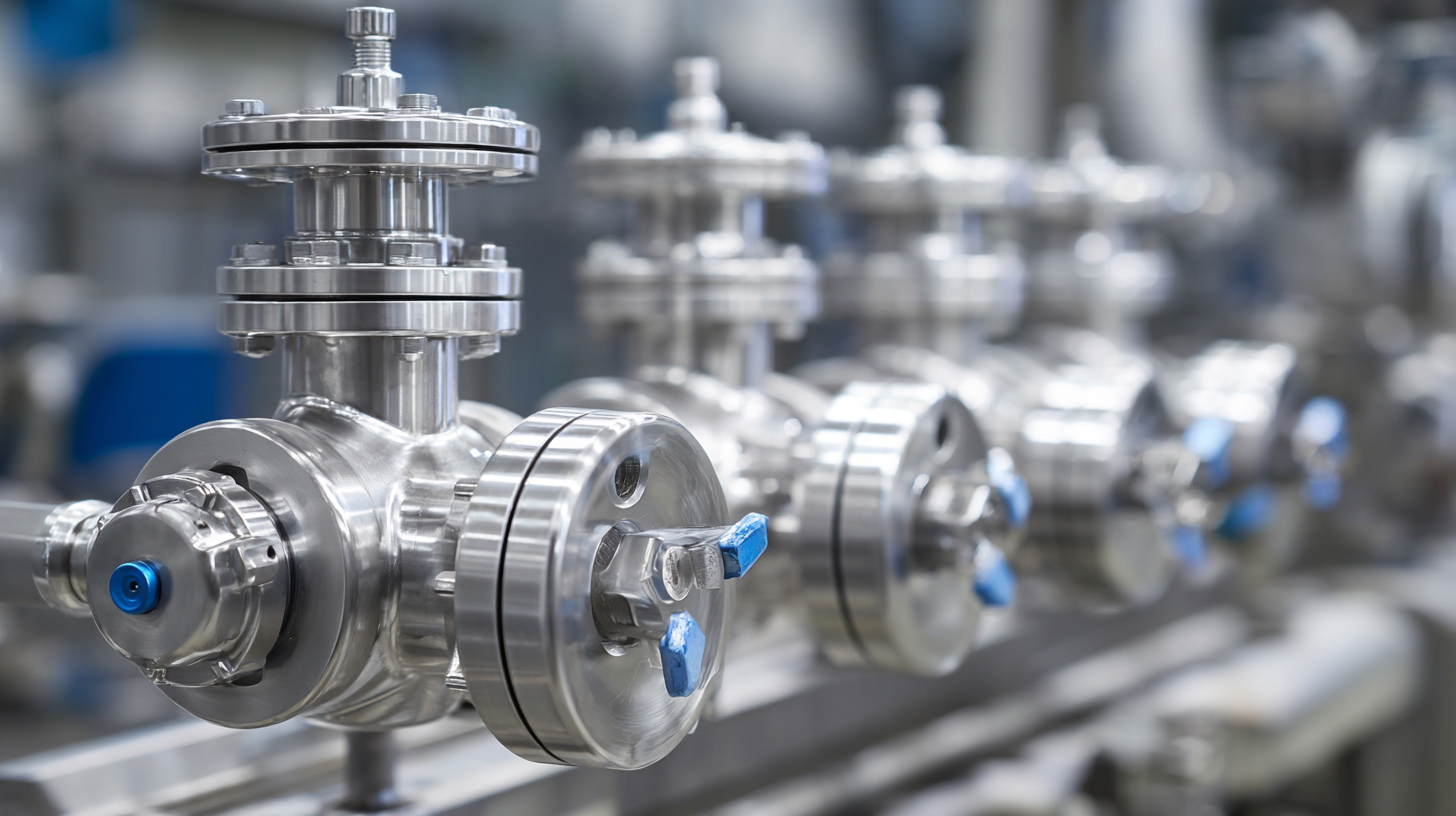

How to Choose the Right Stainless Valves for Your Industrial Applications

In today's industrial landscape, the importance of selecting the right components for operational efficiency is paramount, particularly when it comes to stainless valves. According to a recent market analysis by MarketsandMarkets, the global stainless steel valves market is projected to reach USD 14.80 billion by 2025, growing at a CAGR of 5.7% from 2020 to 2025. This growth can be attributed to the increasing demand for durability and corrosion resistance in various sectors, including chemical processing and water treatment.

As industries strive for enhanced performance and reliability, understanding the specific requirements of stainless valves becomes essential. Whether it’s for high-pressure applications or corrosive environments, making informed decisions can significantly impact productivity and operational costs. This blog will guide you through the critical factors to consider when selecting stainless valves tailored to your industrial needs.

Factors to Consider When Choosing Stainless Valves for Various Industries

When selecting stainless steel valves for industrial applications, several critical factors must be taken into consideration to ensure optimal performance and longevity. One primary consideration is the type of stainless steel used; for instance, a recent industry report by MarketsandMarkets indicates that the global stainless steel market is projected to reach USD 220 billion by 2026, driven by its durability and corrosion resistance. The most commonly used grades, such as 304 and 316, have distinct properties that make them suitable for different environments. Grade 304 is often sufficient for food and beverage applications, while Grade 316 is preferred in more corrosive environments such as chemical processing due to its enhanced resistance to chlorides.

Additionally, valve type and design are paramount. According to a report from Research and Markets, the demand for globe valves in the oil and gas sector is expected to grow significantly, highlighting the necessity of understanding specific industry needs. Whether it's a ball valve for quick shut-off, a butterfly valve for regulating flow, or a check valve to prevent backflow, selecting the right valve type can directly impact operational efficiency. Furthermore, factors such as pressure rating, temperature range, and compatibility with various media should be evaluated to ensure that the chosen valve performs reliably under the specific conditions of the application.

Understanding the Different Types of Stainless Valves and Their Applications

When choosing the right stainless valves for your industrial applications, it's essential to understand the different types available and their specific uses. Stainless steel valves are renowned for their durability and corrosion resistance, making them ideal for industries such as oil and gas, chemical processing, and water treatment.

Common types include ball valves, gate valves, and globe valves, each serving unique functions. For example, ball valves provide excellent sealing and quick shut-off, while gate valves are perfect for on/off control with minimal pressure drop.

Tips for selecting the right valve include assessing the pressure and temperature requirements of your application, as well as considering the type of fluid being transported. It’s crucial to ensure that the valve material is compatible with the fluid to prevent corrosion and leaks. Additionally, factor in the installation space available, as different valves have varying sizes and operational mechanisms.

Another important aspect is understanding the flow direction and the pressure drop across the valve. A valve with a high flow coefficient (Cv) will allow more fluid to pass through with less pressure loss. Always consult with manufacturers or industry experts to get recommendations tailored to your specific needs, ensuring optimal performance and longevity of your system.

Key Performance Metrics for Selecting Stainless Valves in Industrial Settings

Selecting the right stainless valves for your industrial applications requires a thorough understanding of key performance metrics. One essential factor is corrosion resistance, especially in aggressive environments. According to a report by the International Stainless Steel Forum (ISSF), stainless steel valves show a significant reduction in degradation compared to carbon steel valves, allowing a lifespan increase of up to 60% in corrosive media applications. This is particularly crucial in chemical processing, where reactive substances can lead to rapid equipment failure.

Another critical metric is pressure and temperature ratings, which determine a valve's suitability for specific applications. The American Society of Mechanical Engineers (ASME) provides guidelines indicating that valves used in high-pressure systems need to withstand conditions up to 3000 psi. Choosing valves that comply with ASME standards can prevent catastrophic failures and enhance safety.

**Tip:** Always assess the specific conditions of your application, including temperature, pressure, and the chemical composition of the fluids involved.

Finally, consider the valve type—ball, gate, or check valves—based on the operational requirements. Some applications necessitate quick shutoff, while others may require precise flow control. Research by the Valve Manufacturers Association highlights that choosing the right type can enhance efficiency by 20% in fluid transport systems.

**Tip:** Consult with valve manufacturers for tailored recommendations on valve selection based on application-specific metrics.

How to Choose the Right Stainless Valves for Your Industrial Applications - Key Performance Metrics for Selecting Stainless Valves in Industrial Settings

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Flow Coefficient (Cv) | Applications |

|---|---|---|---|---|---|

| Ball Valve | 316 Stainless Steel | 1500 | -20 to 450 | 10 | Water, Oil, Gas |

| Gate Valve | 304 Stainless Steel | 2000 | -20 to 400 | 12 | Pipelines, HVAC |

| Globe Valve | 316L Stainless Steel | 600 | -4 to 450 | 8 | Flow Regulation |

| Check Valve | 304 Stainless Steel | 1500 | -20 to 350 | 4 | Backflow Prevention |

| Butterfly Valve | 316 Stainless Steel | 150 | -10 to 300 | 25 | Water Treatment |

The Role of Corrosion Resistance in Stainless Valve Selection Process

When selecting stainless valves for industrial applications, corrosion resistance plays a pivotal role in ensuring long-term performance and reliability. Since these valves will often be exposed to harsh environments, choosing the right material can prevent premature failures and costly downtimes. Stainless steel grades, such as 304 and 316, offer varying levels of corrosion resistance, making it crucial to assess the specific conditions they will face.

Tip: Understand the operating environment of the valves. If exposure to chlorides or other corrosive substances is expected, opting for higher-grade materials like 316 stainless steel can significantly enhance durability.

Moreover, the type of fluid passing through the valves should influence your decision. Corrosive fluids can accelerate wear and tear, leading to leaks and malfunctions. Hence, combining knowledge of the valve's material properties with the characteristics of the fluids can help ensure optimal performance.

Moreover, the type of fluid passing through the valves should influence your decision. Corrosive fluids can accelerate wear and tear, leading to leaks and malfunctions. Hence, combining knowledge of the valve's material properties with the characteristics of the fluids can help ensure optimal performance.

Tip: Conduct a thorough analysis of the fluids involved. Consider factors such as pH levels, temperature, and pressure to select valves that will withstand specific operational stresses without degrading.

Industry Standards and Certifications Impacting Stainless Valve Choices

When it comes to selecting the right stainless valves for industrial applications, understanding industry standards and certifications is crucial. Various regulatory bodies establish guidelines that influence valve performance, safety, and compatibility with specific processes. For instance, adherence to standards such as ISO, ASME, and API ensures that the valves comply with operational requirements and industry best practices. These certifications can affect factors ranging from corrosion resistance to pressure ratings, ultimately impacting the lifespan and reliability of the valves used in complex industrial systems.

Furthermore, the presence of reputable manufacturers in the market, reaffirming their commitment to quality, plays a significant role in guiding purchasing decisions. When selecting stainless valves, it is essential to consider not only the technical specifications aligned with industry standards but also the brand’s reputation for quality and customer support. This multifaceted approach ensures that the valves selected not only meet the necessary safety and performance criteria but also provide long-term cost-effectiveness and operational efficiency in industrial applications.

Related Posts

-

How to Choose the Right Needle Valve for Global Industrial Applications

-

Exploring Innovative Alternatives to Stainless Fittings: Industry Insights and Trends

-

7 Best Butterfly Valves for Enhanced Industrial Performance in 2024

-

Comparative Analysis of Steel and Fittings: Selecting the Best Options for Global Buyers

-

7 Best Flange Gasket Options You Didn't Know Existed

-

5 Key Factors for Sourcing the Best Flanges and Fittings in Today's Global Market