Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

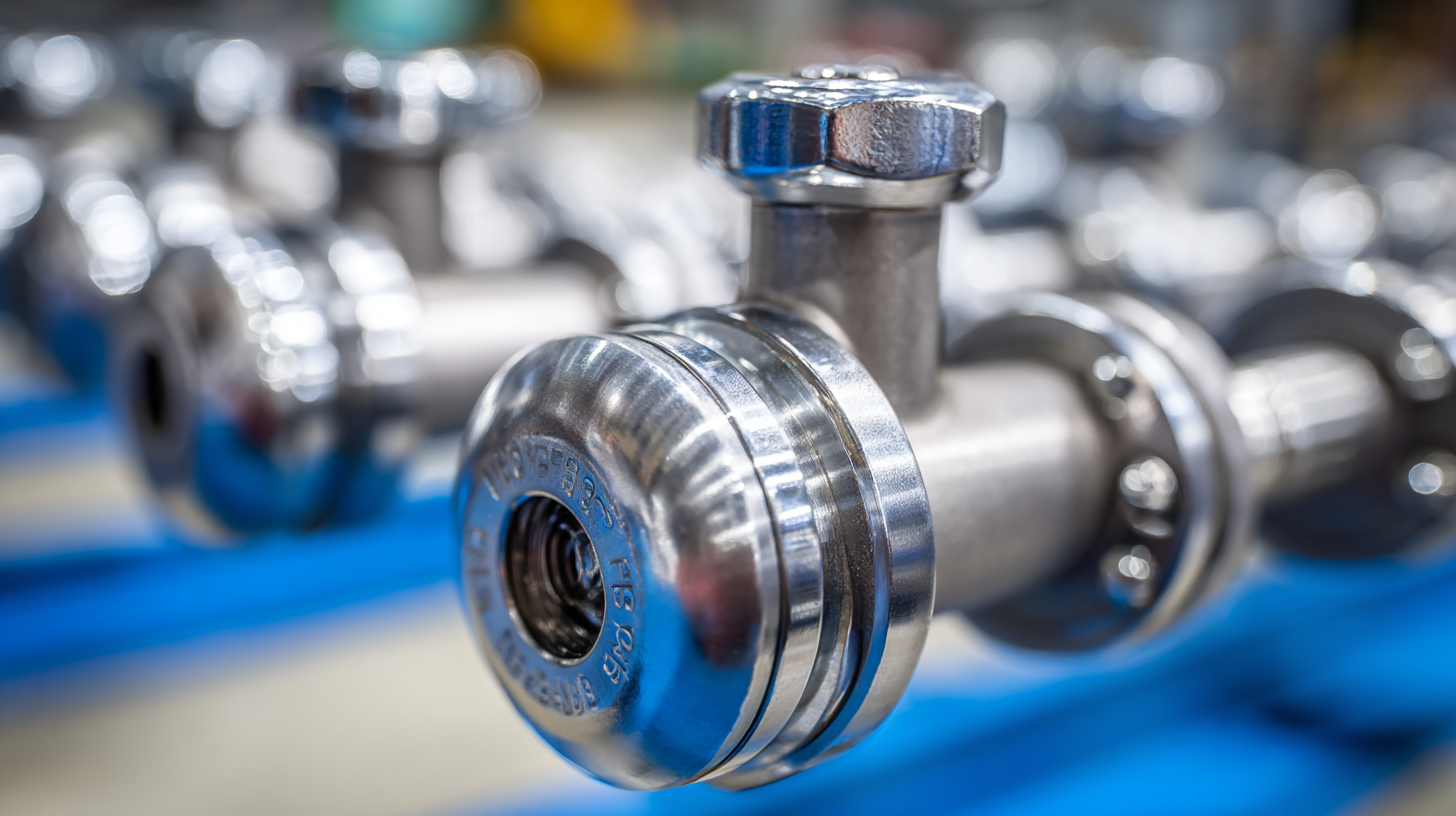

How to Choose the Right Stainless Steel Ball Valves for Your Application

In the realm of fluid control systems, the selection of appropriate stainless steel ball valves is critical to ensuring operational efficiency and longevity. According to a report by MarketsandMarkets, the global ball valve market is projected to reach $14.81 billion by 2025, driven by increased demand across various industries, including oil and gas, water and wastewater treatment, and chemical processing. The durable and corrosion-resistant properties of stainless steel make these valves an ideal choice, especially in harsh environments where reliability and performance are paramount. However, with a plethora of options available, understanding the specific requirements of your application—such as pressure ratings, size, and end connections—is essential for making an informed choice.

This guide will navigate you through the key considerations in selecting the right stainless steel ball valves for your needs, ensuring optimal operational success.

Understanding Different Types of Stainless Steel Ball Valves

When selecting stainless steel ball valves for your application, it's essential to understand the various types available to ensure optimal performance and durability. Stainless steel ball valves can be categorized primarily into two types: floating ball valves and trunnion ball valves. Floating ball valves have a ball that is held in place by the compression of the body seals, allowing it to float and shift under pressure, making them ideal for low-pressure applications. In contrast, trunnion ball valves feature a mounted ball that provides stability and is suitable for high-pressure and large-diameter applications.

When selecting stainless steel ball valves for your application, it's essential to understand the various types available to ensure optimal performance and durability. Stainless steel ball valves can be categorized primarily into two types: floating ball valves and trunnion ball valves. Floating ball valves have a ball that is held in place by the compression of the body seals, allowing it to float and shift under pressure, making them ideal for low-pressure applications. In contrast, trunnion ball valves feature a mounted ball that provides stability and is suitable for high-pressure and large-diameter applications.

Tips: When evaluating ball valves, consider factors such as the operating pressure, temperature, and the type of media being handled. Materials like 304 and 316 stainless steel are commonly used, with 316 being preferable for corrosive environments due to its higher nickel and molybdenum content. Additionally, think about the valve's end connections; options include threaded, welded, and flanged connections, each designed for specific installation environments.

Tips: Always check the manufacturer's specifications and certifications, as industry standards play a significant role in ensuring that the valve meets safety and performance requirements. Consulting recent industry reports can provide valuable insights into the trends and innovations in stainless steel ball valve technology, helping you make an informed decision tailored to your system’s needs.

Key Factors to Consider for Your Application Requirements

When selecting stainless steel ball valves for specific applications, several key factors must be considered to ensure optimal performance and durability. According to a report from the Valve Manufacturers Association, over 60% of valve failures can be attributed to improper selection, highlighting the importance of understanding your specific requirements. Key considerations include pressure ratings, temperature ranges, and the type of fluid being handled. For instance, a valve operating in a high-temperature environment may need special seals and materials to prevent degradation, while valves used in corrosive applications might require higher grades of stainless steel, such as 316SS, to withstand chemical attacks.

Another crucial factor is the valve's size and flow characteristics. The American National Standards Institute emphasizes the need to match the valve size to the piping system to ensure efficient flow and minimize pressure drops. Engineers should calculate the required flow rate and consider the Cv (flow coefficient) value of the valve, which indicates its efficiency in allowing fluid to pass through. Proper sizing and selection based on these parameters not only enhance system performance but also extend the lifespan of the valve, ultimately resulting in reduced maintenance costs and improved operational reliability.

How to Choose the Right Stainless Steel Ball Valves for Your Application - Key Factors to Consider for Your Application Requirements

| Factor | Description | Importance Level |

|---|---|---|

| Material | Consider corrosion resistance and suitability for the fluid | High |

| Size | Select based on pipe diameter and flow requirements | Medium |

| Pressure Rating | Ensure the valve can handle the system pressure | High |

| Temperature Range | Select valves that operate within the temperature limits | Medium |

| End Connections | Choose connections compatible with your piping system | Low |

| Actuation Type | Decide between manual, electric, or pneumatic actuation | Medium |

| Standards Compliance | Check if the valve meets industry standards and regulations | High |

Evaluating Material Grades and Pressure Ratings for Valves

When selecting stainless steel ball valves, evaluating material grades and pressure ratings is crucial to ensure optimal performance for your specific application. Stainless steel valves are available in various grades, with 304 and 316 being the most commonly used. For applications exposed to corrosive environments, such as chemical processing or marine settings, 316 stainless steel is preferred due to its enhanced resistance to pitting and corrosion, as supported by reports from the International Stainless Steel Forum (ISSF), which notes that 316 can withstand chloride exposure better than 304.

Pressure ratings also play a significant role in valve selection, as they determine the maximum pressure the valve can handle without failure. The American Society of Mechanical Engineers (ASME) provides guidelines for pressure ratings that can be found in the ASME B16.34 standard. Typically, stainless steel ball valves are rated for ANSI classes such as 150, 300, or 600, where higher classes indicate higher pressure carrying capabilities. In practice, choosing a valve that exceeds your system's maximum operating pressure can add a safety margin.

**Tips:** Always verify the pressure ratings based on the temperature of your application, as the performance of stainless steel may vary significantly with temperature changes. Additionally, consider conducting a thorough compatibility analysis of your valve material with the fluids it will handle to avert corrosion or degradation over time.

Selecting the Right Size and Connection Types for Optimal Performance

Choosing the right size and connection types for stainless steel ball valves is crucial for achieving optimal performance in various industrial applications. According to a 2022 report by MarketsandMarkets, the global ball valve market is projected to reach USD 10.5 billion by 2026, reflecting the growing importance of selecting the correct valve specifications. The size of the valve must be compatible with the piping system in which it will be installed, as improper sizing can lead to flow restrictions or excessive pressure drops, negatively affecting system efficiency.

Connection types also play a significant role in the performance of ball valves. Common connection methods include threaded, flanged, and welded, each offering distinct advantages depending on the application. A recent study in the Journal of Mechanical Engineering reported that flanged connections provide better stability in high-pressure environments, making them preferred for oil and gas applications, where safety and durability are paramount. Conversely, threaded connections are often chosen for low-pressure systems due to their ease of installation and maintenance. Understanding these specifics can significantly enhance the reliability and efficiency of fluid control systems, ultimately contributing to improved operational outcomes.

Maintenance and Longevity: Ensuring Your Valve Choice Pays Off

When selecting stainless steel ball valves, considering maintenance and longevity is paramount to ensure that your investment remains productive over time. Regular inspections and proper maintenance schedules can prevent common issues such as leaks and corrosion. A well-maintained valve can significantly increase its lifespan, reducing the need for costly replacements and minimizing downtime in your operations.

In addition to routine checks, choosing valves that come with durable seals and corrosion-resistant finishes can enhance their longevity. Stainless steel's inherent properties provide an excellent resistance to a variety of chemicals and environmental factors, but specific applications may require additional protective coatings. Assessing the working environment and the compatibility of the valve materials with the fluids they will handle can guide you in making a more informed choice, ultimately benefiting your system’s efficiency and reliability.

Stainless Steel Ball Valves Maintenance and Longevity

Related Posts

-

How to Choose the Right Stainless Fittings for Your Industrial Needs

-

A Comprehensive Guide to Choosing the Right Weld Fittings for Your Projects

-

5 Key Benefits of Choosing the Right Fittings and Valves for Your Projects

-

5 Key Factors for Sourcing the Best Flanges and Fittings in Today's Global Market

-

How to Achieve Perfect Weld Bend Specifications for Your Projects

-

The Role of Butterfly Valves in Modern Industry: A Comprehensive Overview