Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

How to Choose the Right Sharpe Ball Valves for Your Needs?

Choosing the right Sharpe ball valves for your needs is crucial. Industry expert John Smith states, “Selecting the right valve ensures system efficiency.” This highlights the impact of proper valve choice.

Sharpe ball valves offer various features suitable for different applications. Their durability and reliability stand out in many industrial settings. However, knowing which specific valve fits your system can be challenging. Factors like pressure, temperature, and fluid type must be considered carefully.

Many users underestimate these variables. They often overlook the importance of matching valve specifications with their operational needs. This can lead to performance issues down the line. Investing time in understanding Sharpe ball valves can save you from costly mistakes. In the end, the right choice can significantly enhance system performance and longevity.

Understanding the Basics of Sharpe Ball Valves and Their Applications

When selecting Sharpe ball valves, understanding their design and applications is crucial. Ball valves are widely used in various industries, such as oil and gas, water treatment, and pharmaceuticals. They provide reliable shut-off capabilities and are essential for controlling flow in piping systems. According to industry data, ball valves account for over 40% of the global valve market.

One critical aspect to consider is the valve material. Stainless steel and brass are common choices, but the right material depends on the fluid being controlled. For aggressive chemicals, a more resistant alloy may be necessary. Understand the chemical properties before making a selection. Many applications fail because of inappropriate material choice.

Tips: Always check the temperature and pressure ratings of the valve. These factors significantly influence long-term performance. It’s also important to consider the valve size. An oversized valve can lead to poor flow conditions. Conversely, an undersized valve may not handle the desired flow rate.

In conclusion, careful selection involves not just focusing on price, but also evaluating the environment in which the valve operates. Errors in selection can lead to costly repairs and operational failures. Regularly reviewing your choices helps to ensure you meet industry standards and maintain efficiency.

Key Factors to Consider When Selecting Sharpe Ball Valves for Industries

Choosing the right ball valves for industrial needs involves several factors. Start by assessing the media they will handle. Different fluids require specific materials. Corrosive substances can damage valves that aren’t made from durable materials. Ensure compatibility to avoid failure.

Next, consider the pressure and temperature conditions. Valves must withstand the operational environment. High-pressure systems need robust construction for safety. Inadequate specifications can lead to leaks or failures. Remember, not all valves can manage extreme conditions.

**Tips:** Always consult technical specifications. This ensures you select the right valve. Sometimes, misjudging required specifications can cause significant problems. Don’t overlook the importance of installation space. Some valves require more space than others.

Finally, evaluate the ease of maintenance. Some designs may be complex and require more downtime. Simpler designs often save time and costs. Take a moment to reflect on maintenance needs before making a choice. Careful selection now can prevent headaches later.

How to Choose the Right Sharpe Ball Valves for Your Needs?

This chart illustrates the key factors to consider when selecting Sharpe ball valves across different industrial applications.

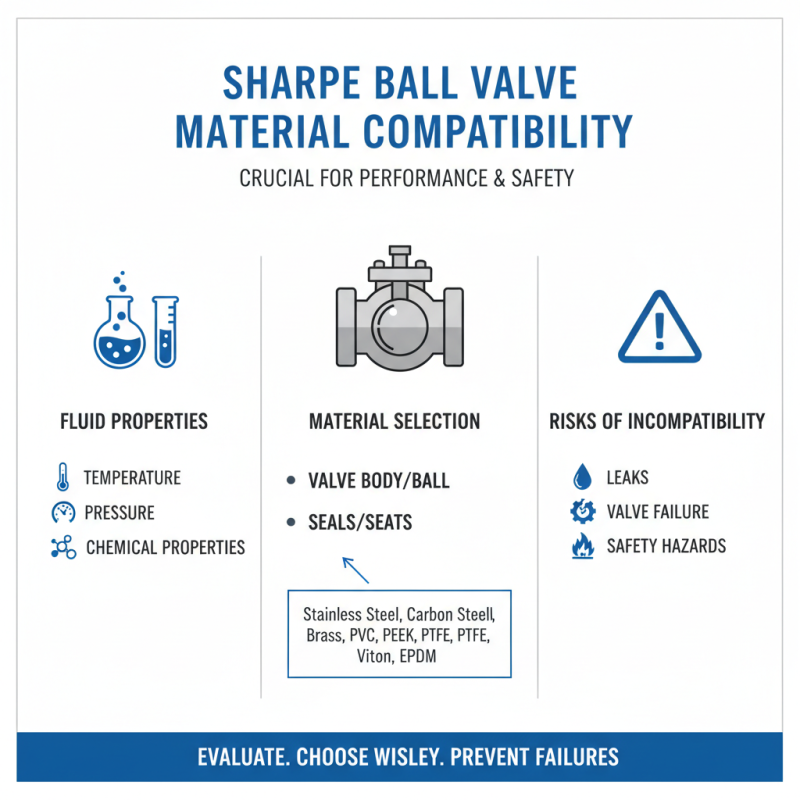

Evaluating Material Compatibility for Sharpe Ball Valves in Fluid Services

When selecting Sharpe ball valves, evaluating material compatibility is crucial. Different fluids interact differently with materials. Consider factors like temperature, pressure, and chemical properties of the fluids involved. Misjudging compatibility can lead to valve failures, leaks, or safety hazards.

Tips: Always refer to material datasheets. Take time to assess the specific service conditions. Cross-check with suppliers about their recommendations.

Not every material is suited for every job. For instance, certain plastics might degrade in high-temperature applications. Metal options can corrode when exposed to aggressive chemicals. Regular assessments can prevent unexpected issues.

Tips: Conduct periodic reviews of material performance. It helps in identifying potential risks early. Stay informed about new materials and technologies emerging in the field.

Analyzing Pressure Ratings and Size Specifications for Optimal Valve Performance

Choosing the right ball valves requires careful consideration of pressure ratings and sizes. Pressure ratings signify the maximum pressure a valve can withstand. This factor directly impacts performance in your specific application. A valve with insufficient pressure rating could fail, leading to leaks and other serious issues. It's crucial to match the valve's rating with the system's operational pressure.

Size specifications also play a vital role. The diameter of the valve affects the flow rate of your system. A valve that is too small can restrict flow, causing inefficiency. Conversely, an oversized valve may lead to turbulence, negatively impacting performance. Evaluating the internal pipe size will help you select the appropriate valve size. Remember, it's a balancing act.

Details matter in this selection. You need to consider the material compatibility with your fluid. The environment around the valve can also lead to problems. The installation area might limit the size you can use. Reflect on these aspects; not addressing them could lead to costly mistakes. Understanding these specifications ensures a smooth operation of your system while optimizing efficiency.

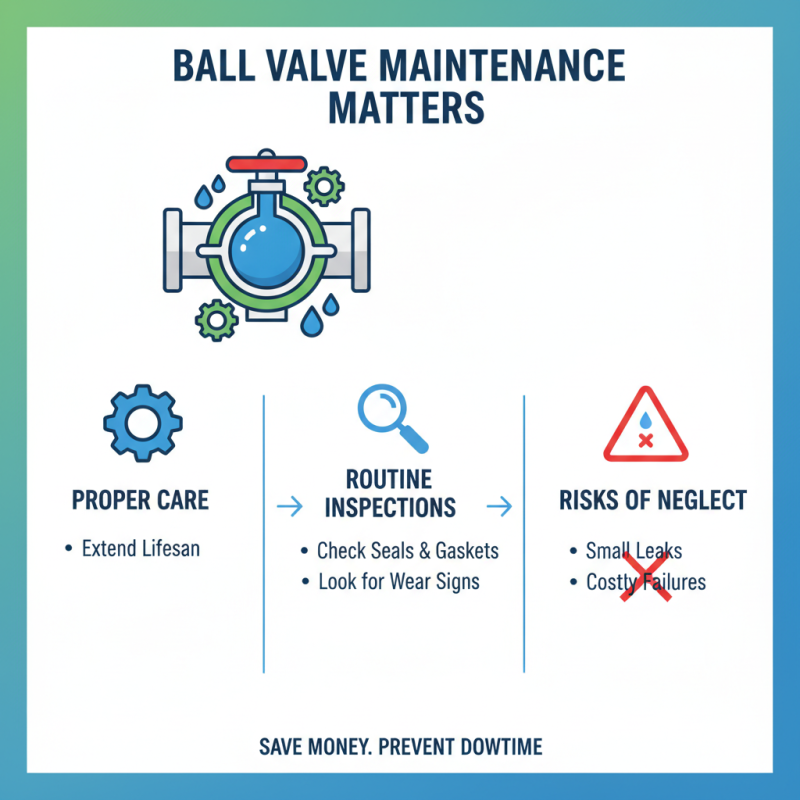

Exploring Maintenance and Durability Aspects of Sharpe Ball Valves in Operations

When selecting ball valves, maintenance is often overlooked. Proper care and routine inspections can lengthen the lifespan of these components. Neglecting maintenance can lead to small leaks, which may escalate into costly failures. Regularly check seals and gaskets for wear. Even small signs of deterioration can indicate future problems.

Durability is another key aspect. The material of the valve significantly impacts its performance. For example, stainless steel valves may withstand harsh environments better than plastic. However, even the strongest materials can fail under extreme conditions. Assessing the operating environment is crucial. Not all valves are designed for every application. Analyze the pressure and temperature requirements.

Another point to consider is the installation process. Poor installation can compromise durability. It’s essential to follow guidelines meticulously. A small oversight here can lead to major issues. Training personnel involved in operations is vital. Encourage them to be vigilant about the state of the valves during routine checks. Ignoring these details can result in safety concerns and operational efficiency loss.

Related Posts

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

-

Top 10 Ball Valves for Optimal Performance and Reliability in Your Projects