Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

How to Choose the Right Flange Valves for Your Plumbing System

In the realm of plumbing systems, one of the critical components that ensure operational efficiency and reliability is the selection of appropriate flange valves. These valves, designed to regulate the flow of fluids through piping systems, play a pivotal role in various applications—from industrial processes to residential installations. According to a recent industry report published by Global Market Insights, the flange valve market is anticipated to experience a significant growth rate of over 5% in the coming years, largely driven by rising infrastructure projects and the increasing demand for efficient fluid control solutions.

Choosing the right flange valves can significantly impact the performance and longevity of plumbing systems. Factors such as material compatibility, pressure rating, and installation specifications must be evaluated to ensure optimum functionality. The American Society of Mechanical Engineers (ASME) provides guidelines emphasizing the importance of valve selection based on operating conditions and service requirements, thus highlighting the need for thorough assessment in the decision-making process. This article aims to provide a comprehensive guide to choosing the right flange valves, equipping professionals and homeowners alike with the knowledge to navigate the complexities of valve selection in their plumbing systems.

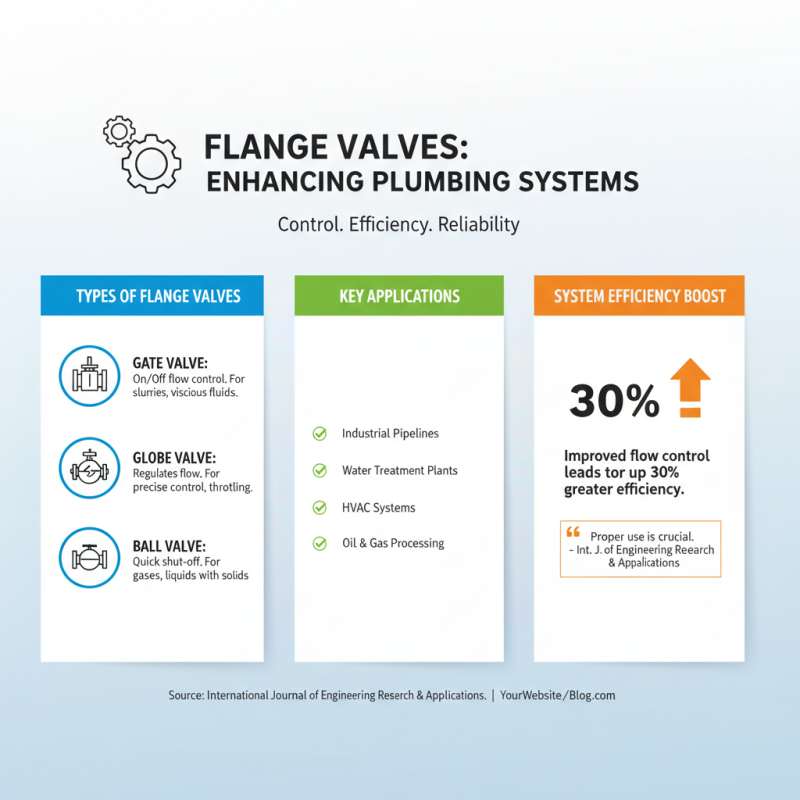

Understanding Flange Valves: Types and Applications

Flange valves play a crucial role in various plumbing systems, offering robust solutions for controlling the flow of liquids and gases. Understanding the different types of flange valves—such as gate, globe, and ball valves—and their specific applications is essential for selecting the right valve for any plumbing project. According to a report by the International Journal of Engineering Research and Applications, the proper use of these valves can enhance system efficiency by up to 30%, depending on the application and operational conditions.

Gate valves are primarily used for on/off control, making them ideal for applications where minimal pressure drop is desired. In contrast, globe valves provide excellent flow regulation, which is necessary in systems where precise control over liquid/gas flow is critical. Ball valves, known for their durability and reliability, are often chosen for quick shutoff applications. Each type has distinct construction features and benefits that cater to specific conditions and requirements within a plumbing system. The Market Research Future report indicates that the demand for flange valves is projected to grow significantly, driven by advances in manufacturing and rising investments in infrastructure.

Proper selection hinges not only on the valve type but also on factors such as pressure ratings, temperature resistance, and the media being transported. Each of these factors can influence the longevity and efficiency of the valve and, by extension, the plumbing system as a whole. A thorough understanding of these parameters will ensure that the selected flange valves perform optimally, ultimately supporting the system's overall performance and reliability.

Key Factors to Consider When Selecting Flange Valves

When selecting flange valves for your plumbing system, several key factors must be taken into account to ensure optimal performance and compatibility.

First and foremost, consider the material of the valve. Flange valves are typically available in a variety of materials such as stainless steel, cast iron, and PVC.

The choice of material should be guided by the specific requirements of your plumbing system, including the type of fluids being transported, the temperature and pressure conditions, and the potential for corrosion.

Choosing the wrong material can lead to premature failure and costly repairs.

Another crucial factor is the size and pressure rating of the valve. It is essential to match the valve size with that of the piping to ensure a proper fit and optimal flow rates.

In addition, the pressure rating should correspond with the system’s operating pressure to prevent leaks or system failures. Flange valves come in different pressure classes, so it is vital to assess the pressure conditions of your plumbing system before making a selection.

By taking these factors into consideration, you can ensure that the flange valves you choose will function effectively within your plumbing system.

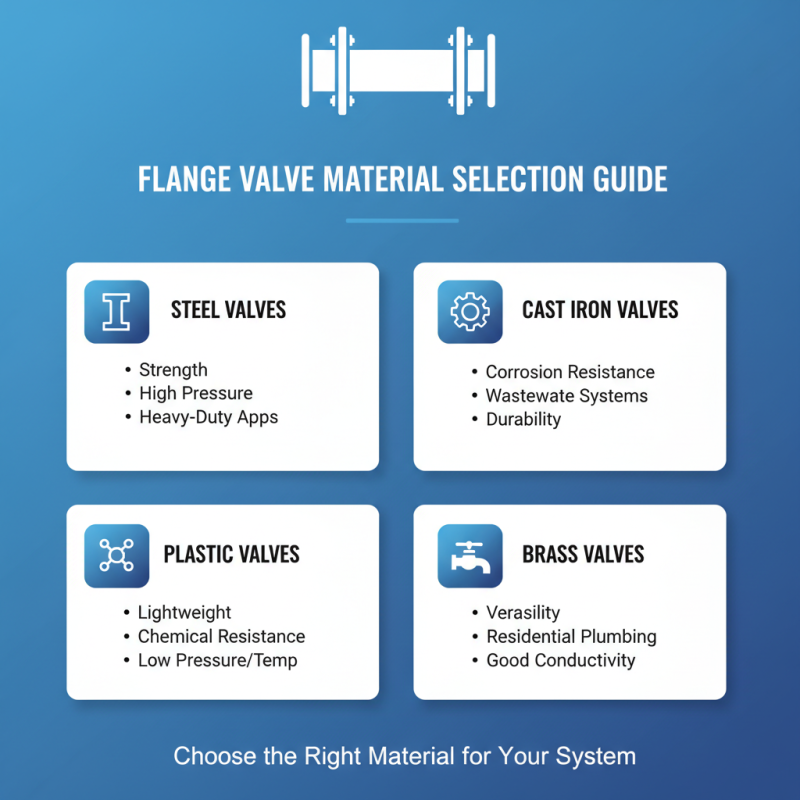

Material Choices for Flange Valves in Plumbing Systems

When selecting flange valves for your plumbing system, it is essential to consider the materials from which the valves are constructed. The choice of material directly impacts the valve's performance, durability, and suitability for specific applications. Common materials for flange valves include steel, cast iron, plastic, and brass. Steel valves are often preferred for their strength and resistance to high pressures, making them ideal for heavy-duty applications. On the other hand, cast iron valves are favored for their strength and corrosion resistance, which is particularly beneficial in wastewater systems.

Transitioning to plastic, these valves offer a lightweight alternative that excels in handling corrosive fluids, making them a popular choice in chemical processing. However, they may not withstand high temperatures as well as metal options. Brass valves are another great choice, particularly in residential plumbing, due to their good resistance to corrosion and ability to perform well under various pressures. By carefully evaluating the material properties, you can select flange valves that meet the specific demands of your plumbing system and ensure optimal functionality and longevity.

Sizing and Pressure Ratings for Proper Flange Valve Selection

When selecting flange valves for your plumbing system, understanding sizing and pressure ratings is crucial. The size of the valve must match the pipe diameter to ensure proper flow and minimize pressure drops. Typically, flange valves are available in various sizes, and choosing the correct diameter is essential for optimal performance. Oversized valves can lead to inefficiencies, while undersized valves may restrict flow, causing potential system failures.

In addition to size, it's imperative to consider the pressure ratings of flange valves. Each valve comes with a specific pressure rating that indicates its maximum operating pressure. This rating should align with the pressure levels in your plumbing system to prevent leaks or bursts. It's essential to assess both the working pressure and any potential surges in your system when making this determination. By prioritizing the correct sizing and appropriate pressure ratings, you can ensure reliable and efficient operation of your plumbing system, ultimately enhancing its longevity and effectiveness.

Flange Valve Selection: Size vs. Pressure Ratings

This chart illustrates the pressure ratings for various flange valve sizes, providing a guide for selecting the appropriate valve for your plumbing system. The values indicate the maximum pressure the valve can handle based on its size.

Installation and Maintenance Tips for Flange Valves

When installing flange valves, it's crucial to ensure proper alignment and tightening of the bolts. Start by cleaning both the valve and the pipe flanges to remove any debris or old sealant. Position the flange valve between the flanges of the piping system, ensuring that the bolt holes are aligned. Use a torque wrench to tighten the bolts in a crisscross pattern to distribute the pressure evenly, which helps to prevent potential leaks. It's essential to follow the recommended torque specifications to avoid damaging the valve or the piping.

Maintaining flange valves is equally important for their longevity and efficiency. Regular inspections should be carried out to check for any signs of wear, corrosion, or leakage. Lubricating the bolts and valve mechanisms can aid in smooth operation and reduce the chances of seizing. Additionally, consider periodic testing of valve functionality to ensure it opens and closes as intended. If any issues are detected, address them immediately—this could involve tightening bolts, replacing seals, or even replacing the valve if necessary. Proper installation and maintenance practices will enhance the performance of flange valves in your plumbing system.

How to Choose the Right Flange Valves for Your Plumbing System - Installation and Maintenance Tips for Flange Valves

| Valve Type | Material | Pressure Rating (psi) | Temperature Rating (°F) | Applications | Maintenance Tips |

|---|---|---|---|---|---|

| Gate Valve | Cast Iron | 150 | -20 to 200 | Water Supply | Check for leaks and rust periodically. |

| Globe Valve | Brass | 200 | -20 to 180 | Oil & Gas | Lubricate moving parts regularly. |

| Ball Valve | PVC | 100 | -10 to 120 | Chemical Processing | Inspect seals and replace damaged parts. |

| Check Valve | Stainless Steel | 300 | -50 to 500 | Water, Oil, Gas | Clean and inspect frequently for proper operation. |

| Butterfly Valve | Aluminum | 150 | -20 to 180 | HVAC Systems | Periodically tighten screws and check for corrosion. |

Related Posts

-

How to Choose the Right Flange Valves for Your Industrial Needs

-

How to Choose the Right Flange Gasket for Your Project

-

How to Choose the Right Flange Gasket for Optimal Sealing Performance: Key Industry Insights

-

How to Choose the Right Floating Ball for Your Industrial Applications

-

How to Choose the Right Stainless Fittings for Your Industrial Needs

-

10 Essential Tips for Choosing the Right Flanges and Fittings