Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

How to Choose the Right Ball Valves for Your Project?

Choosing the right ball valves for your project can be challenging. With various designs available, each has its unique features. Understanding these features is crucial for effective use.

Ball valves are essential components in many systems. They control the flow of liquids and gases. Their design allows for quick on/off operation. However, selecting the right one is not straightforward. You must consider the specific requirements of your project.

Take time to evaluate the material and size of the ball valves. The application may call for corrosion-resistant materials. Also, the pressure rating is vital. Sometimes, a valve may look perfect, yet it fails in specific applications. Learning from these mistakes can lead to better choices in the future.

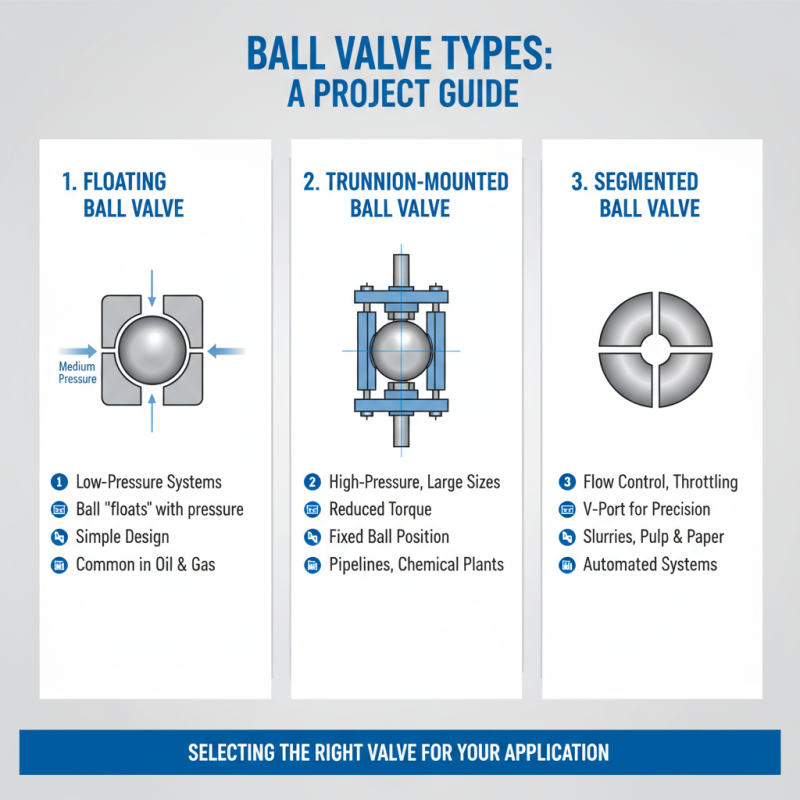

Understanding Different Types of Ball Valves and Their Applications

When selecting ball valves for your project, understanding their types is essential. There are three main types: floating, trunnion-mounted, and segmented. Each type has specific applications and advantages. Floating ball valves are common in low-pressure systems. They rely on the medium pressure to close the valve. This type is often used in oil and gas applications due to its simplicity.

Trunnion-mounted ball valves, however, are suitable for high-pressure operations. They feature a mounted ball that reduces wear on seals. These valves are frequently found in power plants and water treatment facilities. A report from MarketsandMarkets indicates that the global ball valve market is expected to reach $10.56 billion by 2025. The rise in demand for efficient flow control is a driving factor.

Segmented ball valves are less common but very effective for regulating flow. Their design allows for precise control and has made them popular in industries like pharmaceuticals. However, choosing the right type can be challenging. Not all applications benefit from the most advanced valves. It's crucial to evaluate the specific requirements of your project. Consider factors like pressure, temperature, and fluid type. Sometimes, the simplest solution is the most effective.

Key Factors to Consider When Selecting Ball Valves for Your Project

Selecting the right ball valves for your project involves considering several key factors. Valve size is critical. The diameter must match the pipe size for optimal flow. According to industry reports, incorrect sizing can lead to inefficiencies, drastically affecting system performance. A poor fit might cause leaks or even system failure.

Material choice plays an essential role as well. Common materials include stainless steel, brass, and plastic. The chosen material should withstand the media and environmental conditions. For example, corrosive fluids require more robust materials like stainless steel. The wrong material could result in premature wear or leakage. Missteps in material selection can have costly repercussions.

Pressure ratings are another aspect to consider. Not all valves can handle the same pressures. Ensuring that the valve’s rating aligns with your system’s requirements is crucial. A mismatch may lead to dangerous failures. Furthermore, valves must fit the intended application—residential, commercial, or industrial. Failing to account for the application's specifics can lead to inefficient operation. Each project will have unique needs. Taking time to evaluate these factors will yield better results.

Comparison of Key Factors in Selecting Ball Valves

Evaluating Material Compatibility for Ball Valves in Various Environments

When selecting ball valves, material compatibility is crucial. Different environments can impact the performance of a valve. Factors like temperature, pressure, and exposure to chemicals must be considered. For example, a valve used in a corrosive environment should be made from resistant materials. This prevents leaks and ensures longevity.

**Tips:** Consider temperature ratings. Make sure they match your project's requirements. Using the wrong material could lead to failure.

The choice between metals, plastics, or composites is important. Each material has unique properties. Stainless steel is strong, while PVC is lightweight. However, both can degrade under specific conditions. Research is vital to avoid costly mistakes.

**Tips:** Keep a log of the substances the valve will encounter. This will guide your material selection. Disregarding this can compromise safety and efficiency.

Sizing and Pressure Ratings: Ensuring Optimal Performance of Ball Valves

Choosing the right ball valves requires careful consideration of sizing and pressure ratings. These factors directly impact valve performance in any project. A properly sized valve ensures efficient flow control. For instance, a valve too small may restrict flow. This could lead to pressure drops and system inefficiencies.

Pressure ratings are equally critical. Each valve has a maximum pressure it can handle. Exceeding this limit can cause failures or leaks. It's vital to assess the system's pressure requirements. A mismatch between the valve and system pressure can jeopardize safety. For high-pressure applications, selecting valves rated for higher pressures is essential.

Reflecting on past experiences can guide future decisions. Mistakes, like choosing the wrong size or pressure rating, can be costly. Learning from these missteps helps improve future project outcomes. Pay attention to specific requirements and consult with experts if needed. Taking time to ensure the right fit makes all the difference.

How to Choose the Right Ball Valves for Your Project? - Sizing and Pressure Ratings: Ensuring Optimal Performance of Ball Valves

| Valve Type | Size (Inches) | Pressure Rating (PSI) | Material | Temperature Rating (°F) |

|---|---|---|---|---|

| Floating Ball Valve | 1 | 150 | Brass | -20 to 250 |

| Trunnion Ball Valve | 2 | 300 | Stainless Steel | -50 to 400 |

| Full Port Ball Valve | 3 | 600 | Carbon Steel | -20 to 300 |

| Full Port Plastic Ball Valve | 1.5 | 150 | PVC | 32 to 140 |

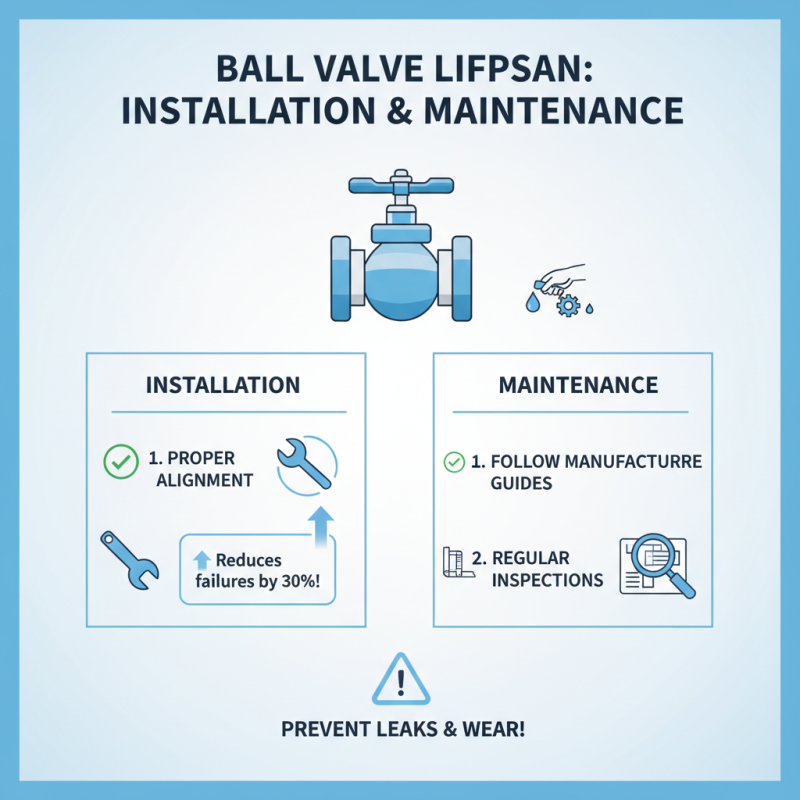

Installation and Maintenance Tips for Longevity of Ball Valves

When it comes to ball valves, installation and maintenance are crucial for extending their lifespan. A study by the Valve Manufacturers Association revealed that improper installation can lead to up to 30% of valve failures. This underscores the importance of ensuring correct alignment and torque during installation. Operators should follow the manufacturer’s guidelines closely. A slightly misaligned valve can increase wear over time, leading to leaks.

Regular maintenance is equally vital. Inspecting ball valves every six months can prevent unexpected failures. A routine check for signs of corrosion or wear can save significant costs in repairs. Interestingly, it’s estimated that 70% of maintenance costs are attributed to unplanned outages. Keeping a close eye on valve performance helps. Use visual inspections and functional tests to assess their condition.

Using the right lubrication is another important aspect. Too much or too little lubrication can cause major issues. Over-lubricating can lead to blockages, while insufficient lubrication could result in catastrophic failure. Many engineers recommend only using manufacturers' specified lubricants to mitigate this risk. Remember, even a small oversight can have significant consequences. Regular training and awareness can help teams stay vigilant about these details.

Related Posts

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

Top 10 Ball Valves for Optimal Performance and Reliability in Your Projects

-

Top 2025 Ball Valves Types You Need to Know for Your Projects

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity