Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

How to Choose the Right Stainless Steel Flanges for Your Project

Choosing the right stainless steel flanges for your project is crucial to ensure durability, reliability, and safety in various applications. As John Smith, a renowned expert in the stainless steel industry, once said, "Understanding the specifications and applications of stainless steel flanges can make or break a project's success." This highlights the importance of making informed decisions when selecting flanges for piping systems.

In the world of stainless steel flanges, the options can be overwhelming, ranging from different grades and sizes to various types tailored for specific applications. Engineers and project managers must navigate these choices with a critical eye to ensure compatibility with the materials and conditions they will face. This article aims to provide a comprehensive guide to help you understand the factors to consider when choosing stainless steel flanges, empowering you to make the right selection for your needs.

By examining the specifications, applications, and types available, we will elucidate how proper selection leads to enhanced performance and longevity in your projects. Whether you're working in construction, manufacturing, or any industry that relies on stainless steel components, this guide will serve as an essential resource for your project planning and execution.

Understanding Different Types of Stainless Steel Flanges Available

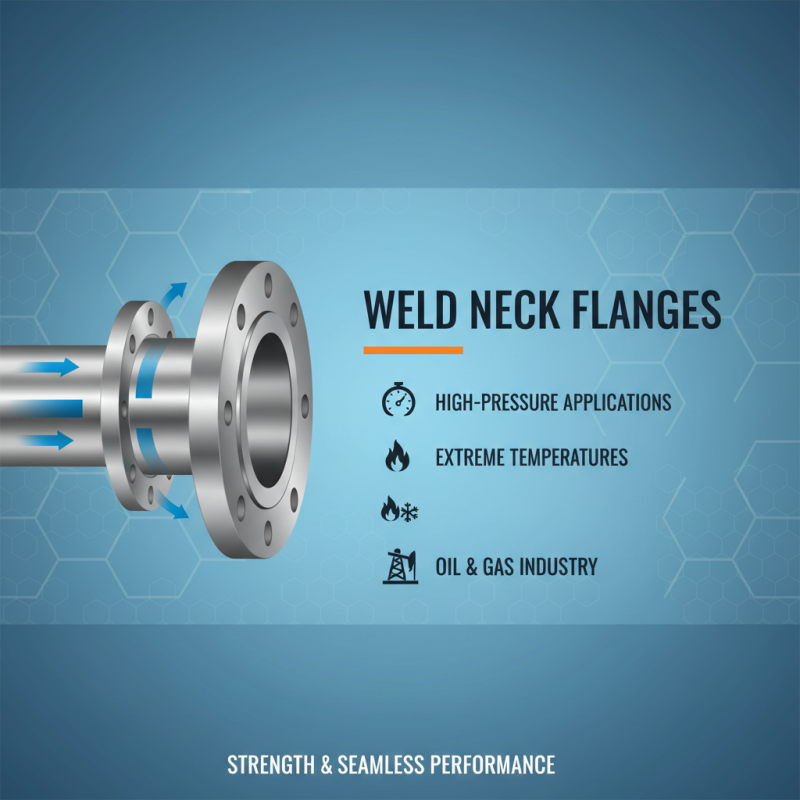

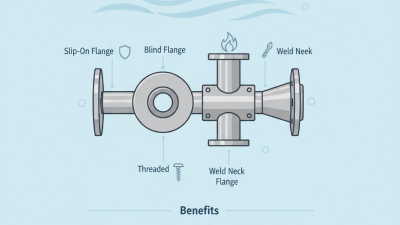

When it comes to selecting stainless steel flanges for your project, understanding the different types available is crucial for ensuring compatibility and performance. Flanges are typically categorized into several types, including weld neck, slip-on, and blind flanges. Weld neck flanges are ideal for high-pressure applications due to their strong, reinforced structure, providing a seamless transition between the flange and the pipe. Their ability to handle extreme temperatures and pressures makes them a popular choice in industries such as oil and gas.

Slip-on flanges, on the other hand, are easier to install and are commonly used in lower-pressure applications. They slide over the pipe and are welded in place, which saves time and labor costs. Similarly, blind flanges serve a unique purpose by closing the ends of pipelines, providing a secure seal while allowing for future access. Understanding the application requirements and the properties of these flange types is essential for selecting the right one for your project, ensuring reliable operation and safety in your piping system.

Factors to Consider When Selecting Stainless Steel Flanges

When selecting stainless steel flanges for your project, there are several key factors to consider. First and foremost, you need to evaluate the application requirements. Understanding the working pressure, temperature, and medium being conveyed is crucial as different flanges are rated for specific conditions. Choosing the right flange material is also essential; not all stainless steels are created equal, and properties such as corrosion resistance and strength should align with your project demands.

Another critical aspect is the flange design and size. Flanges come in various types (such as weld neck, slip-on, and blind) and dimensions. Ensure that the selected flange matches the piping system in terms of size and compatibility. Additionally, consider the connection type—whether it will be welded, bolted, or threaded—as this will affect installation and future maintenance.

Tips: Always consult design standards and guidelines relevant to your industry to ensure compliance and safety. If you are uncertain about material specifications or sizes, seek advice from a professional or use detailed engineering resources. Lastly, keep in mind the availability of flanges, as sourcing the right type promptly can impact your project timeline.

Assessing the Environment and Application for Flange Selection

When choosing stainless steel flanges, understanding the environment and application is crucial for ensuring optimal performance and durability. Different environments can expose flanges to varying levels of temperature, pressure, and corrosive elements. For instance, in extremely high-temperature applications, materials with better thermal stability should be chosen, while corrosive environments might require flanges made from specialized alloys that can withstand harsh chemicals. Assessing factors such as moisture levels and the presence of salt or chemicals can dictate the type of stainless steel required, positioning choices like 304 or 316 grades at the forefront of selection criteria.

In addition to environmental considerations, the specific application also plays a significant role in flange selection. The type of piping system, whether it’s for water, gas, or different industrial fluid services, influences the design and specifications of flanges. For example, a flange used in a water treatment facility may not require the same level of corrosion resistance as one used in an offshore oil rig. Furthermore, ensuring that the flange can handle expected loads and align properly with connecting equipment is essential to avoid leaks and failures. Each project demands a tailored approach to flange selection, taking into account both the immediate operational conditions and the long-term implications of material choices.

Evaluating Quality Standards and Specifications for Flanges

When selecting stainless steel flanges for your project, it is essential to evaluate their quality standards and specifications. One of the first things to consider is the material grade of the stainless steel used in the flanges. Common grades, such as 304 and 316, offer different levels of corrosion resistance and mechanical properties, which can significantly impact the longevity and performance of the flange in specific environments. Understanding the composition and characteristics of these grades will help ensure that the flanges meet the demands of your application, especially in industries like oil and gas, marine, or food processing, where exposure to harsh conditions is prevalent.

In addition to the material grade, it is crucial to check that the flanges conform to relevant industry standards, such as ASTM, ASME, or ANSI. These standards provide guidelines on dimensional tolerances, pressure ratings, and testing methods, ensuring that the flanges can withstand the specified operating conditions. Furthermore, looking for third-party certifications can offer additional assurance of quality, as they indicate that the flanges have undergone rigorous testing and adhere to strict guidelines. By carefully assessing these factors, you can make informed decisions that enhance the reliability and efficiency of your project's piping system.

Common Mistakes to Avoid When Choosing Stainless Steel Flanges

When selecting stainless steel flanges for a project, one of the most common mistakes is overlooking the importance of flange material specifications. Each project may require flanges made from different grades of stainless steel depending on factors like temperature, pressure, and environmental exposure. Failing to match the flange material to the project requirements can lead to corrosion, leaks, or even catastrophic failure. It’s crucial to not only consider the mechanical properties of the material but also its compatibility with the fluids it will come into contact with.

Another frequent error is disregarding flange standards and dimensions. Flanges come in various standards (like ANSI, ASME, or DIN), each with specific dimensional requirements. Ignoring these standards can result in mismatched components, which can complicate installation and ultimately compromise system integrity. Ensuring that the flanges conform to the required specifications helps maintain uniformity across components, thus simplifying the assembly process and ensuring a reliable operation. Taking the time to verify standards and dimensions can save considerable time and resources in the long run.

Related Posts

-

Understanding the Impact of Stainless Steel Flanges in the Oil and Gas Industry with Key Market Insights

-

What is Stainless Steel Flanges Types Uses and Benefits You Should Know

-

Exploring the Rise of Steel Flanges in 2025 China Import Export Trends at the 138th Canton Fair

-

7 Best Butterfly Valves for Enhanced Industrial Performance in 2024

-

How to Choose the Right Flanges and Fittings for Your Project

-

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity