Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

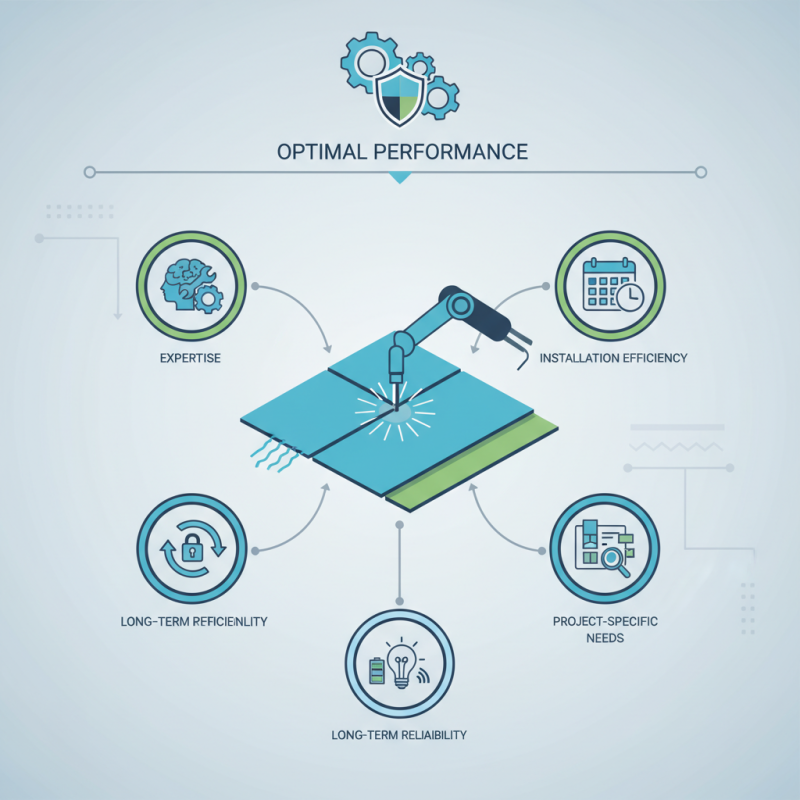

Best Geomembrane Welding Machines for Optimal Performance?

In the world of waterproofing and containment, geomembrane welding machines play a vital role. Experts agree on their importance. Dr. Andrew Smith, a leading figure in this field, states, "The quality of geomembrane welding can significantly impact project durability." This highlights the need for optimal performance from these machines.

The selection of the best geomembrane welding machine is essential. It affects both installation efficiency and long-term reliability. Each machine has unique features, and not all are suitable for every project. Some operators experience difficulties, sometimes due to machine complexities or inadequate training.

Investing in the right equipment is a challenge. Many companies face this dilemma. It's easy to overlook the importance of choosing a machine that matches specific project demands. In this rapidly evolving industry, staying updated with the latest advancements is crucial. Performance and efficiency should never be compromised.

Overview of Geomembrane Welding Machines and Their Applications

Geomembrane welding machines play a crucial role in various construction and engineering applications. These machines are used to join geomembranes, typically made of synthetic materials. They create strong and reliable seals for containment systems. Each project may require different welding techniques. The effectiveness of the weld depends on the machine's specifications and operator skill.

Applications of geomembrane welding machines vary widely. They are used in waste containment facilities, irrigation canals, and mining operations. The choice of machine often depends on the materials being welded and environmental conditions. Unfortunately, not every machine performs optimally in all situations. Factors like temperature and pressure can significantly affect the quality of the weld. Operators must adjust their techniques to maintain standards.

While some machines offer advanced features, they may not be user-friendly. Difficulty in operation can lead to poor welds and project delays. Training and experience are essential for operators to handle these machines effectively. It is critical to test equipment and materials regularly to ensure compatibility. Regular maintenance and careful monitoring can improve performance but may require additional resources. Ultimately, selecting the right machine is vital for achieving better results in geomembrane projects.

Performance Comparison of Geomembrane Welding Machines

Key Features to Consider When Choosing Welding Machines

Choosing the right geomembrane welding machine is crucial for optimal performance. When selecting a machine, consider its temperature control. A machine with precise temperature settings ensures consistent welding quality. Look for models that offer adjustable heat levels. This feature allows welders to adapt to different materials and thicknesses.

Another important feature is the speed of the welding process. Faster machines can increase your productivity. However, speed should never compromise the quality of the weld. A well-welded seam is vital for the integrity of geomembrane installations. Ensure that the machine maintains a good balance between speed and quality.

Tips to remember include checking user reviews. Real-world feedback can provide insights into a machine’s reliability. Additionally, consider the machine’s portability. If you work on various sites, a lightweight option can save you time and effort. Don’t forget to factor in the budget. Quality doesn’t always mean expensive. Some affordable machines deliver excellent results.

Lastly, reflect on your specific needs. What materials do you typically work with? Knowing your main applications can guide you in making the best choice. A machine that excels in one area may not suit another. Take the time to evaluate your options carefully.

Top Brands and Models for Geomembrane Welding Efficiency

When it comes to geomembrane welding, efficiency is crucial. Selecting the right machine can significantly impact project success. Various top models offer features that enhance performance. For instance, some machines have advanced temperature control. This ensures weld quality and minimizes defects during operation. Additionally, portable options allow for flexibility on-site.

Durability in machines is essential. Many models are designed for heavy use, yet portability can compromise sturdiness. Users may find that lightweight machines struggle with larger projects. Some models are better suited for continuous welding, while others excel in precision tasks. Understanding project requirements can guide equipment choices.

Despite the advancements, users often face challenges. It’s common to encounter issues with inconsistent settings or calibration. This can lead to weak seams. Regular maintenance is essential to keep machines performing at their best. Reflecting on past projects, operators often identify areas for improvement and adjustments needed for future tasks.

Maintenance Tips for Enhancing the Performance of Welding Machines

To enhance the performance of geomembrane welding machines, regular maintenance is crucial. Ensure that the machine is clean and free of debris. Each component should be inspected for wear and tear. Over time, parts can degrade, impacting welding quality. A detailed check of the heating elements can prevent uneven welds. If they show signs of damage, immediate replacement is necessary.

Calibration of the welding machine is essential. Misalignment can lead to faulty welds and project delays. Periodically adjust the settings based on the material used. Referencing the manufacturer’s guidelines can help you achieve accurate results. Additionally, training operators on proper handling can reduce mishaps. A lack of skill may lead to wasted materials or improper sealing.

Consider the environment where the machines operate. High humidity or extreme temperatures can affect performance. Storing machinery in a controlled setting can mitigate these issues. Not addressing environmental factors can compromise weld integrity. Keep track of performance metrics to identify areas needing attention. Reflecting on these details will foster improvements in future projects.

Future Trends in Geomembrane Welding Technology

The future of geomembrane welding technology is evolving rapidly. As industries seek more efficient and durable solutions, the integration of advanced materials and automation is becoming essential. Recent reports indicate that the global geomembrane market is projected to grow to $3 billion by 2027, driven by increasing demands in landfill, mining, and water containment sectors. This growth is pushing manufacturers to innovate their welding technologies for better performance.

Emerging trends point toward the use of robotic systems for welding applications. These robots can enhance precision and reduce labor costs. A study highlighted that incorporating robotic welding can increase productivity by up to 30%. However, challenges remain. The initial investment in robotic systems can be substantial, and not every facility may have the budget for such advancements. Companies must weigh the benefits against the costs effectively.

Here are some tips for embracing new welding technologies: Invest in training for your team to leverage these advanced tools effectively. Monitor industry reports for the latest developments and success stories. Also, consider trial projects to evaluate new technologies before full-scale implementation. Adapting to these trends is vital for maintaining a competitive edge. Balancing innovation with practical resources is both a challenge and an opportunity.

| Model | Welder Type | Max Temperature (°C) | Welding Speed (m/min) | Power (W) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | Hot Air Welder | 600 | 10 | 1600 | 3.5 |

| Model B | Extrusion Welder | 500 | 5 | 2000 | 4.2 |

| Model C | Peel & Stick Welder | 650 | 8 | 1800 | 3.0 |

| Model D | Plasma Welder | 700 | 6 | 2200 | 5.0 |