Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

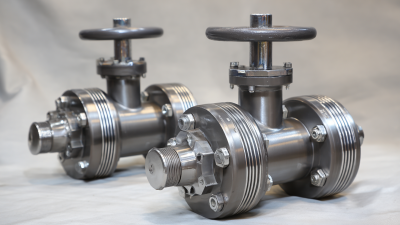

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity

In the modern industrial landscape, the longevity and reliability of equipment are paramount to operational success. One key component that significantly contributes to this longevity is the use of stainless valves. These valves, known for their corrosion resistance and durability, play a crucial role in a variety of industrial applications, from chemical processing to water treatment. The intrinsic properties of stainless steel not only enhance the performance of valves but also lessen the likelihood of equipment failure, thereby reducing maintenance costs and downtime.

Moreover, the adoption of stainless valves is becoming increasingly important as industries face growing demands for efficiency and sustainability. As manufacturers seek solutions that align with environmental regulations and operational excellence, stainless valves stand out due to their ability to withstand harsh conditions while maintaining structural integrity over extended periods of use. This makes them a favorable choice for industries looking to invest in equipment that offers both functional performance and longevity. In this context, we explore the top five benefits of incorporating stainless valves into industrial systems, highlighting their pivotal role in enhancing overall productivity and reliability.

Advantages of Stainless Valves for Enhanced Durability in Harsh Environments

Stainless valves are increasingly becoming the preferred choice in various industrial applications, particularly due to their exceptional durability in harsh environments. According to a report by Allied Market Research, the global stainless steel valve market is projected to reach $22.9 billion by 2027, driven by the rising demand for corrosion-resistant materials in industries such as oil and gas, chemicals, and water management. Stainless valves, particularly those made from grades like 304 and 316, offer excellent resistance to corrosive agents, high temperatures, and pressure fluctuations, ensuring reliability even in the most challenging scenarios.

Moreover, stainless valves are noted for their long service life, which greatly reduces maintenance costs and downtime for industries operating within severe conditions. Research from the Valve Manufacturers Association highlights that switching to stainless steel valves can yield a 30% increase in lifespan compared to traditional carbon steel options. This increased longevity translates into substantial cost savings over time, as companies can avoid frequent replacements and repairs. Furthermore, the inherent strength and fatigue resistance of stainless steel enable these valves to handle extreme operational stresses, making them an ideal choice for critical applications where safety and performance are non-negotiable.

Cost-Effectiveness: Long-Term Savings with Stainless Steel Valves

Stainless steel valves have gained popularity in industrial applications due to their impressive longevity and cost-effectiveness. One of the most significant advantages of these valves is their ability to reduce long-term maintenance and replacement costs. Unlike other materials that may corrode or degrade over time, stainless steel stands the test of time, ensuring that businesses do not need to frequently invest in new valve systems. This durability not only translates into fewer disruptions in operations but also contributes to substantial savings on labor and material costs.

**Tip:** When considering valve materials, assess the specific environmental conditions of your application. Stainless steel's resistance to corrosion makes it ideal for industries exposed to harsh chemicals or extreme temperatures, helping you minimize unexpected costs in the long run.

Additionally, the thermal efficiency of stainless steel valves enhances their performance and effectiveness in various processes. With lower energy losses, businesses experience improved operational efficiency, ultimately driving down costs associated with energy consumption. This aspect further emphasizes the financial prudence of implementing stainless steel valves in industrial settings.

**Tip:** Regular inspections can help maintain the optimum functioning of stainless steel valves. Early identification of wear or issues can prevent costly downtime and ensure that your investment continues to yield savings.

Top 5 Benefits of Using Stainless Valves in Industrial Applications for Longevity - Cost-Effectiveness: Long-Term Savings with Stainless Steel Valves

| Benefit | Description | Long-Term Savings |

|---|---|---|

| Corrosion Resistance | Stainless steel valves resist corrosion, reducing maintenance costs. | Up to 30% on repairs over 10 years. |

| Durability | They withstand high pressure and temperature, ensuring a long lifespan. | Cost savings due to reduced replacement frequency. |

| Maintenance-Free | Minimal upkeep required compared to other materials. | Saves on labor costs and downtime. |

| Versatility | Suitable for various industrial applications. | Reduces the need for multiple valve types. |

| Safety | Minimizes leak risks, enhancing operational safety. | Prevents costly accidents and downtime. |

Corrosion Resistance: Ensuring Reliability in Chemical Processing

Corrosion resistance is a critical factor in ensuring reliability within chemical processing environments, especially in industrial applications where equipment is often exposed to harsh substances. Stainless valves, known for their exceptional resistance to corrosion, play a vital role in minimizing downtime and maintenance costs associated with equipment failure. The use of stainless valves allows facilities to operate efficiently while upholding safety standards, as these valves can withstand the corrosive effects of chemicals, thus extending their lifespan and functionality.

Moreover, advancements in technologies, such as atmospheric plasma treatment, are enhancing the corrosion resistance of materials used in wastewater and chemical processing systems. This approach not only improves the durability of valves and other components but also addresses the necessity for effective corrosion monitoring and inhibition. By incorporating stainless steel valves into such systems, industries can enhance their operational reliability, ultimately achieving long-term benefits and cost efficiencies in their processes. The ongoing developments in materials science further support the integration of stainless valves, ensuring that industrial applications can meet the rigorous demands of modern chemical processing.

Maintenance Ease: Simplifying Upkeep for Industrial Systems

Stainless valves are increasingly favored in industrial applications due to their longevity and ease of maintenance. One of the key advantages they offer is the simplification of upkeep for complex systems. Unlike traditional valves that may require frequent inspections and repairs due to corrosion or wear, stainless valves are resistant to harsh environments and aggressive media, significantly reducing the need for routine maintenance. This durability allows operators to focus on other critical areas of production rather than being bogged down by valve issues.

Additionally, the construction of stainless valves facilitates straightforward maintenance procedures. Their design often allows for easier disassembly and reassembly, which means that technicians can quickly perform necessary inspections or replacement of components without extensive downtime. This not only enhances operational efficiency but also minimizes labor costs associated with maintenance work. Ultimately, the use of stainless valves leads to a more streamlined industrial process, supporting overall productivity while ensuring system reliability.

Versatility: Applicability of Stainless Valves Across Various Industries

Stainless valves are increasingly recognized for their versatility, making them an ideal choice across various industrial applications. These valves are resistant to corrosion, making them suitable for industries such as food processing, pharmaceuticals, and chemical manufacturing. In environments where sanitation is crucial, the smooth surface of stainless steel prevents contamination and facilitates easy cleaning, ensuring compliance with industry standards.

When selecting stainless valves, consider the specific needs of your application. Tip: Always assess the chemical compatibility of the valve materials with the fluids they will handle to avoid potential failures. Additionally, think about the temperature ranges and pressures in your operations, as different stainless steel grades may perform better under varying conditions.

Another essential tip is to keep durability in mind. Investing in high-quality stainless valves not only contributes to longevity but can also reduce maintenance costs in the long run. Selecting valves with appropriate seals and fittings can enhance their performance and reliability, making them a smart choice for any industrial setup.

Related Posts

-

Top 5 Stainless Valves to Invest in for 2025: Best Options and Features

-

5 Essential Tips for Choosing the Right Ball Valves for Your Applications

-

How to Choose the Right Stainless Valves for Your Industrial Applications

-

5 Best Gate Valves for Efficient Fluid Control in Industrial Applications

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

How to Choose the Right Stainless Steel Ball Valves for Your Needs