Quality Products

At a Fair Price

Wholesale Provider

Of Valves & Fittings

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- Blog

- Careers

- Get a Quote

- HOME

- Products

- Ball Valves

- Bull Plugs & Swages

- Butterfly Valves

- Check Valves

- Cushion / Flow Tees & Bleed Rings

- Enhanced Oil Recovery

- Floating Ball Valves

- Foot Valves

- Forged Steel Fittings

- Forged Steel Outlets

- Gaskets-Insulation Kits

- Gate Valves

- Gate, Globe & Check Valves

- Malleable Fittings

- Needle Valves

- Nipples

- Piston Valves

- Plug Valves

- Stainless Steel Flanges, Fittings & Nipples

- Strainers

- Studs

- Trunnion

- Unions

- Weld Fittings & Flanges

- Manufacturers

- Advance

- American Block

- Anvil

- Balon

- Bonney Forge

- Champion

- Clayton Mark

- Crane

- Daniel

- DMIC

- GMI

- Galli & Cassina

- Hackney-Ladish

- JMC

- Lone Star

- MATCO

- Marpac-McCanna

- National Flange

- National Gasket

- Nordstrom

- Nutron

- PPI

- SHARPE

- SMI

- TEXSTEAM

- TEX-THREAD

- Titan

- USA Fastner

- Vogt

- Weld Bend

- Westbrook

- Wheatley

- Williams

- WKM

- Wolar

- Locations

- Contact

- About

- Careers

- Get a Quote

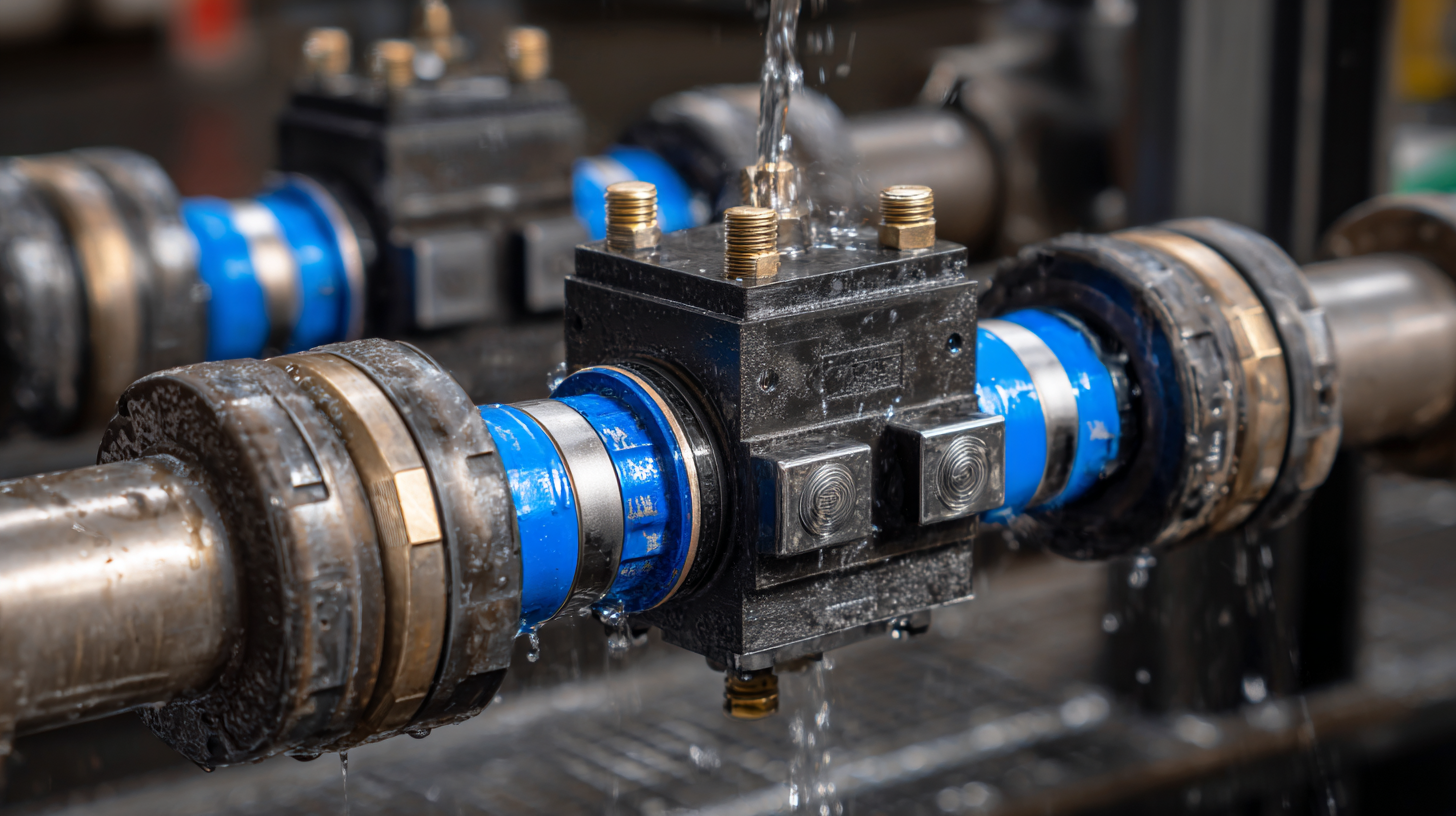

Discover the Benefits of Using Sharpe Ball Valves for Your Industrial Applications

In the ever-evolving industrial landscape, the selection of the right valve type is crucial for optimizing operational efficiency and safety. One standout option gaining traction is the Sharpe ball valve, renowned for its reliability and robust performance across various applications. According to a recent market report by Grand View Research, the global ball valve market is projected to reach $10.68 billion by 2025, with a significant contribution from high-performance variants like the Sharpe ball valves.

These valves not only offer superior flow control and minimal pressure drop but also ensure durability and reduced maintenance costs, attributes that are vital in industries such as oil and gas, water treatment, and chemical processing. By understanding the advantages of implementing Sharpe ball valves, industries can enhance productivity while ensuring compliance with stringent safety standards.

Benefits of Sharpe Ball Valves: Enhanced Flow Control in Industrial Systems

Sharpe ball valves stand out in industrial applications primarily due to their ability to provide enhanced flow control, crucial for maintaining efficiency in various systems. Unlike traditional gate valves that often suffer from issues like turbulence and pressure loss, the design of ball valves allows for a smoother flow path. According to recent studies, the dynamics of flow through different valve types highlight the advantages of the ball valve's spherical closure mechanism, which minimizes flow separation and significantly reduces the risk of cavitation compared to their gate counterparts.

Furthermore, the operational efficiency of industrial processes can greatly benefit from the reduction in energy loss provided by Sharpe ball valves. Data indicates that switching from gate valves to ball valves can result in up to a 30% decrease in energy costs associated with flow regulation. This enhanced flow control not only improves system performance but also extends the lifespan of piping systems by reducing wear and tear. Implementing these valves can lead to noticeable improvements in production capacity and reliability in industrial operations, ultimately fostering a more sustainable approach to managing resources.

Discover the Benefits of Using Sharpe Ball Valves for Your Industrial Applications

| Benefit | Description | Application |

|---|---|---|

| Enhanced Flow Control | Provides precise control over fluid flow, improving process efficiency. | Chemical Processing |

| Durability | Manufactured from robust materials, ensuring long service life. | Oil and Gas |

| Low Maintenance | Designed to minimize wear and tear, resulting in lower maintenance costs. | Water Treatment |

| Versatility | Can be used in various industrial applications across different sectors. | Pharmaceuticals |

| Safety Features | Incorporates features that prevent leaks and failures, enhancing operational safety. | Food Processing |

Understanding the Durability of Sharpe Ball Valves: Materials and Lifespan

Sharpe ball valves are renowned in industrial applications for their exceptional durability, primarily attributable to the high-quality materials used in their construction. Typically made from corrosion-resistant alloys such as stainless steel, these valves can withstand harsh operating conditions, including extreme temperatures and pressures. According to a report from the Flow Control Industry Association, stainless steel ball valves have an average lifespan of over 20 years when properly maintained, making them a cost-effective choice for manufacturers looking to minimize downtime and repair costs.

Sharpe ball valves are renowned in industrial applications for their exceptional durability, primarily attributable to the high-quality materials used in their construction. Typically made from corrosion-resistant alloys such as stainless steel, these valves can withstand harsh operating conditions, including extreme temperatures and pressures. According to a report from the Flow Control Industry Association, stainless steel ball valves have an average lifespan of over 20 years when properly maintained, making them a cost-effective choice for manufacturers looking to minimize downtime and repair costs.

The lifespan of Sharpe ball valves is further enhanced by their design, which incorporates features such as blow-out proof stems and resilient seals. These design choices minimize the risk of leaks and failures, allowing for reliable operation in critical applications. In fact, the American Society of Mechanical Engineers (ASME) notes that utilizing high-quality ball valves can improve operational efficiency by as much as 15% by reducing the frequency of maintenance interventions and enhancing system reliability. Thus, investing in Sharpe ball valves not only ensures longevity but also fosters improved performance in industrial processes.

Cost Efficiency: The Economic Advantage of Using Sharpe Ball Valves in Operations

When considering industrial applications, cost efficiency is a paramount concern. Sharpe ball valves offer an economic advantage that can significantly lower operational expenses. Their robust design reduces the risk of leaks and failures, leading to decreased maintenance costs and downtime. By minimizing these disruptions, companies can allocate resources more effectively, enhancing overall productivity. Investing in high-quality Sharpe ball valves ensures long-term reliability, which translates to substantial savings over time.

Moreover, Sharpe ball valves are designed for quick installation and ease of use, further contributing to cost efficiency. The straightforward operation allows for faster project timelines, reducing labor costs associated with installation and maintenance. Their durable construction means they perform well across a range of temperatures and pressures, decreasing the need for frequent replacements or repairs. As industries strive to balance quality and budget, the economic benefits of using Sharpe ball valves make them an attractive option for optimizing operations and ensuring financial sustainability.

Maintenance Simplified: How Sharpe Ball Valves Reduce Downtime and Repair Costs

Sharpe ball valves are revolutionizing industrial applications by simplifying maintenance procedures, leading to significant reductions in both downtime and repair costs. These valves are designed with longevity and reliability in mind, featuring robust materials that withstand harsh operating environments. Their streamlined design allows for quick disassembly and reassembly, making routine inspections and servicing more efficient than traditional valve systems. Consequently, industries can minimize the time spent on maintenance activities, allowing for increased productivity on the production line.

Moreover, the innovative engineering of Sharpe ball valves reduces the likelihood of malfunctions and leaks, which are common causes of costly repairs. With fewer moving parts and a reliable sealing mechanism, these valves often require less frequent replacements. This efficiency translates to lower maintenance budgets and a reduced risk of unexpected shutdowns. Overall, the choice of Sharpe ball valves not only enhances operational effectiveness but also contributes to considerable long-term cost savings for businesses looking to optimize their industrial processes.

Benefits of Using Sharpe Ball Valves in Industrial Applications

Safety First: The Role of Sharpe Ball Valves in Mitigating Industrial Hazards

The role of Sharpe ball valves in industrial settings extends far beyond mere functionality—they are essential in enhancing safety measures within various applications. According to a report by the American National Standards Institute, about 20% of industrial accidents are associated with inadequate valve systems. By utilizing high-quality ball valves, industries can significantly mitigate risks associated with leaks and pressure buildups, securing both the workplace and the workforce.

Sharpe ball valves are specifically designed to withstand high pressures and corrosive environments, which makes them ideal for critical applications in oil and gas, chemical processing, and manufacturing. A study conducted by the Process Safety Institute indicates that facilities that implement robust valve systems, including ball valves, see a reduction in accidents by up to 30%. This enhanced safety is not merely about compliance; it directly correlates to improved operational efficiency and reduced downtime, effectively contributing to the bottom line.

Related Posts

-

How to Choose the Right Flange Gasket for Your Industrial Needs

-

How to Choose the Right Flange Gasket for Your Project

-

The Essential Guide to Choosing the Right Stainless Flanges for Your Projects

-

Exploring Alternative Weld Fittings: Innovative Solutions for Global Procurement Needs

-

Unlocking the Advantages of Custom Steel Flanges for Your Next Project: A Comprehensive Guide

-

Maximizing Efficiency and Longevity with Titan Valves in Industrial Applications